EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Die casting is a vital process in modern manufacturing, used to create high-precision, durable parts quickly and efficiently. Two primary methods for die casting are hot chamber die casting and cold chamber die casting. Both processes are essential in the production of metal components, but they differ in their approaches, applications, and benefits. This article explores these two methods in detail and helps you determine which is the best fit for your specific needs.

Hot chamber die casting is a process where molten metal is injected into a mold using a machine that is directly connected to the molten metal source. This method is most suitable for metals with a lower melting point, such as zinc, magnesium, and lead alloys. The key advantages of hot chamber die casting include: - **Faster Cycle Times**: Because the machine is constantly connected to the molten metal, the process is quicker compared to cold chamber die casting. - **Precision and Consistency**: Hot chamber machines can produce parts with great consistency, making them ideal for high-volume production. - Cost-Effective: The process is less energy-intensive, which results in lower operational costs for mass production. This method is commonly used in industries like automotive and electronics, where speed and efficiency are critical for producing smaller parts with high precision.

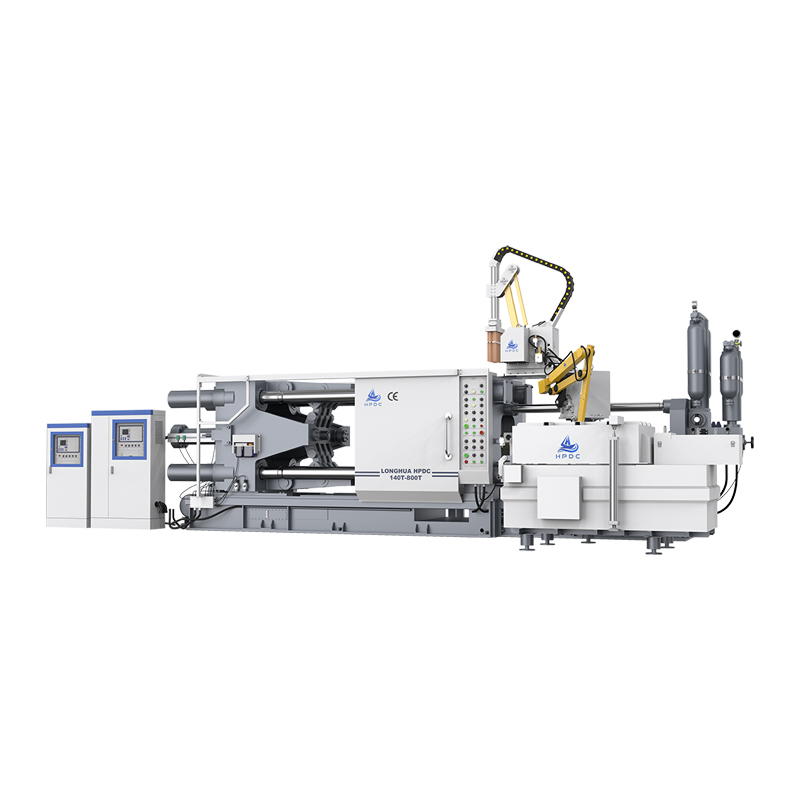

Cold chamber die casting involves transferring molten metal into the die casting machine, which is not directly connected to the molten metal source. This method is typically used for metals with higher melting points, such as aluminum, brass, and copper. Key benefits of cold chamber die casting include: - **Versatility**: Cold chamber machines can work with a variety of metals, including those that cannot be handled in hot chamber die casting. - **High-Pressure Applications**: This method is suited for high-pressure die casting, making it ideal for applications that require strong, durable parts. - **Durability**: Cold chamber machines are generally more robust, as they do not experience the same wear from constant exposure to molten metal. Cold chamber die casting is widely used in industries like aerospace, industrial equipment, and automotive for parts that require higher strength and heat resistance.

Understanding the differences between these two die casting methods is crucial when deciding which process best suits your production needs.

In hot chamber die casting, the molten metal is injected into the mold directly from the furnace through a gooseneck. In contrast, cold chamber die casting requires the molten metal to be manually transferred to the injection chamber before being forced into the mold.

Hot chamber die casting is primarily used for metals with lower melting points, such as zinc, magnesium, and lead. Cold chamber die casting, on the other hand, can handle metals with higher melting points like aluminum, brass, and copper.

Hot chamber die casting offers faster cycle times, which can significantly reduce production costs, especially in high-volume runs. Cold chamber die casting, while versatile, tends to have longer cycle times due to the additional step of transferring molten metal to the machine.

Hot chamber die casting machines are simpler in design and require less maintenance compared to cold chamber machines, as they don’t need to handle high-pressure applications. However, the frequent exposure to molten metal leads to more wear and tear. Cold chamber die casting machines are more robust and durable but are more expensive to maintain and repair.

Hot chamber die casting is best suited for smaller, high-volume parts made from metals like zinc and magnesium, while cold chamber die casting is ideal for larger, stronger parts made from metals like aluminum and copper. The choice depends on your specific requirements for part size, strength, and production speed.

- **Faster Cycle Times**: The process is highly efficient for mass production, especially when using metals with lower melting points. - **Precision and Consistency**: The ability to produce parts with high accuracy makes it ideal for small, intricate components. - **Cost-Efficient**: Hot chamber die casting is less energy-intensive, leading to lower operational costs.

- **Limited Metal Types**: It is restricted to metals with lower melting points, limiting its range of applications. - **Machine Wear**: The constant exposure to molten metal results in more frequent machine maintenance.

- **Metal Versatility**: Can handle metals with higher melting points, such as aluminum and brass, allowing for a wider range of applications. - **High-Pressure Capability**: Ideal for casting large, high-strength parts that require greater durability and precision. - **Robust Machinery**: Cold chamber machines are designed for long-term use and can withstand high pressures.

- **Slower Cycle Times**: Cold chamber die casting is slower due to the manual transfer of molten metal. - **Higher Operational Costs**: The process is more energy-intensive, leading to higher operational costs.

Hot chamber die casting is the best choice when you need to produce small to medium-sized parts in high volumes. It is particularly effective for parts that don’t require high-strength metals and where quick turnaround times are crucial. Industries such as electronics and automotive often prefer hot chamber die casting for its efficiency and cost-effectiveness.

Cold chamber die casting is better suited for parts that require high-strength metals like aluminum, brass, and copper. It is the ideal choice when the parts must withstand higher temperatures and pressures. This method is widely used in industries such as aerospace and heavy machinery, where durability and precision are paramount.

When comparing the cost-efficiency of hot and cold chamber die casting, the key factors to consider include: - **Initial Setup Costs**: Hot chamber machines tend to have lower initial setup costs compared to cold chamber machines. - **Operating Costs**: Hot chamber die casting is more energy-efficient and typically results in lower operating costs, especially for high-volume production. - **Maintenance Costs**: Cold chamber machines have higher maintenance costs due to their more complex design and the need for more robust components.

- **Tazimac**: Hot chamber die casting offers faster production times, making it ideal for industries where speed is essential. However, it is limited to lower-melting-point metals. - **CSMFG**: Cold chamber die casting excels in handling high-temperature metals like aluminum, making it the preferred choice for industries requiring high-strength parts. - **Beta Die Casting**: Hot chamber die casting is highly efficient for mass production but is best for smaller, non-ferrous metal parts. - **Surewingaming**: Cold chamber die casting offers more versatility for complex, high-precision parts that need to withstand higher temperatures. - **Aludie Casting**: Hot chamber die casting is cost-effective for industries focused on high-volume production, but cold chamber die casting is better for tougher, high-pressure applications. - **CEX Casting**: Cold chamber die casting is recommended for industries like aerospace that require parts made from high-strength metals.

Both hot chamber and cold chamber die casting have their unique advantages and disadvantages. Hot chamber die casting is faster and more cost-effective for high-volume production of smaller parts made from lower-melting-point metals. Cold chamber die casting, on the other hand, is better suited for high-strength applications requiring tougher metals like aluminum and brass. The choice between the two methods depends on your production requirements, the metals being used, and the part specifications. By understanding the strengths of each method, you can make an informed decision that meets your manufacturing needs.