EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| ITEMS | Unit | Specification |

| Clamping Force | KN | 1400 |

| Opening stroke | mm | 350 |

| Die thickness(Min--Max) | mm | 200~500 |

| Space between tie bars | mm | 420*420 |

| Ejector stroke | mm | 80 |

| Ejector force | KN | 100 |

| Injection position(0 as center) | mm | 0,-100 |

| Injection force(intensification) | KN | 180 |

| Injection stroke | mm | 320 |

| Plunger diameter | mm | ¢40 ¢50 ¢60 |

| lnjection weight(aluminum) | Kg | 1.3 |

| Casting pressure (intensification) | MPa | 143/92/64 |

| Max. casting area(40Mpa) | CM2 | 350 |

| Injection plunger penetration | mm | 120 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 12 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 4.6*1.2*1.5 |

| Machine lifting reference weight | T | 4.5 |

| Oil tank capacity | L | 300 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 1450 |

| Opening stroke | mm | 350 |

| Die thickness(Min--Max) | mm | 250~500 |

| Space between tie bars | mm | 429*429 |

| Ejector stroke | mm | 85 |

| Ejector force | KN | 108 |

| Injection position(0 as center) | mm | 0,- 100 |

| Injection force(intensification) | KN | 220 |

| Injection stroke | mm | 320 |

| Plunger diameter | mm | ¢40 ¢50 ¢60 |

| lnjection weight(aluminum) | Kg | 1.6 |

| Casting pressure (intensification) | MPa | 175/112/77 |

| Max. casting area(40Mpa) | CM2 | 362 |

| Injection plunger penetration | mm | 115 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 12 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 4.6*1.2*1.5 |

| Machine lifting reference weight | T | 4.5 |

| Oil tank capacity | L | 480 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 1600 |

| Opening stroke | mm | 360 |

| Die thickness(Min--Max) | mm | 200~550 |

| Space between tie bars | mm | 440*440 |

| Ejector stroke | mm | 80 |

| Ejector force | KN | 100 |

| Injection position(0 as center) | mm | 0 ,- 140 |

| Injection force(intensification) | KN | 180 |

| Injection stroke | mm | 320 |

| Plunger diameter | mm | ¢40 ¢50 ¢60 |

| lnjection weight(aluminum) | Kg | 1.5 |

| Casting pressure (intensification) | MPa | 143/92/64 |

| Max. casting area(40Mpa) | CM2 | 400 |

| Injection plunger penetration | mm | 120 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 12 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.2*1.5*2.05 |

| Machine lifting reference weight | T | 5.2 |

| Oil tank capacity | L | 500 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 1600 |

| Opening stroke | mm | 380 |

| Die thickness(Min--Max) | mm | 200~550 |

| Space between tie bars | mm | 460*460 |

| Ejector stroke | mm | 85 |

| Ejector force | KN | 108 |

| Injection position(0 as center) | mm | 0,-140 |

| Injection force(intensification) | KN | 270 |

| Injection stroke | mm | 340 |

| Plunger diameter | mm | ¢40 ¢50 ¢60 |

| lnjection weight(aluminum) | Kg | 1.8 |

| Casting pressure (intensification) | MPa | 214/137/95 |

| Max. casting area(40Mpa) | CM2 | 400 |

| Injection plunger penetration | mm | 110 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.5*1.5*2.35 |

| Machine lifting reference weight | T | 6 |

| Oil tank capacity | L | 520 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 1800 |

| Opening stroke | mm | 380 |

| Die thickness(Min--Max) | mm | 200~550 |

| Space between tie bars | mm | 480*450 |

| Ejector stroke | mm | 80 |

| Ejector force | KN | 110 |

| Injection position(0 as center) | mm | 0,-140 |

| Injection force(intensification) | KN | 270 |

| Injection stroke | mm | 350 |

| Plunger diameter | mm | ¢50 ¢60 ¢70 |

| lnjection weight(aluminum) | Kg | 2.4 |

| Casting pressure (intensification) | Mpa | 112/78/57 |

| Max. casting area(40Mpa) | CM2 | 450 |

| Injection plunger penetration | mm | 130 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.22*1.5*2.35 |

| Machine lifting reference weight | T | 6.7 |

| Oil tank capacity | L | 600 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 2000 |

| Opening stroke | mm | 380 |

| Die thickness(Min--Max) | mm | 200~550 |

| Space between tie bars | mm | 480*480 |

| Ejector stroke | mm | 80 |

| Ejector force | KN | 110 |

| Injection position(0 as center) | mm | 0,-140 |

| Injection force(intensification) | KN | 270 |

| Injection stroke | mm | 350 |

| Plunger diameter | mm | ¢50 ¢60 ¢70 |

| lnjection weight(aluminum) | Kg | 2.4 |

| Casting pressure (intensification) | MPa | 135/93 |

| Max. casting area(40Mpa) | CM2 | 500 |

| Injection plunger penetration | mm | 135 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.32*1.6*2.35 |

| Machine lifting reference weight | T | 7.5 |

| Oil tank capacity | L | 600 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 2200 |

| Opening stroke | mm | 400 |

| Die thickness(Min--Max) | mm | 200~600 |

| Space between tie bars | mm | 510*510 |

| Ejector stroke | mm | 90 |

| Ejector force | KN | 120 |

| Injection position(0 as center) | mm | 0,-140 |

| Injection force(intensification) | KN | 270 |

| Injection stroke | mm | 370 |

| Plunger diameter | mm | ¢40 --¢70 |

| lnjection weight(aluminum) | Kg | 2.8 |

| Casting pressure (intensification) | MPa | 152/106/77 |

| Max. casting area(40Mpa) | CM2 | 550 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.8*1.6*2.4 |

| Machine lifting reference weight | T | 8.5 |

| Oil tank capacity | L | 600 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 2800 |

| Opening stroke | mm | 420 |

| Die thickness(Min--Max) | mm | 250~600 |

| Space between tie bars | mm | 560*560 |

| Ejector stroke | mm | 100 |

| Ejector force | KN | 110 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 300 |

| Injection stroke | mm | 350 |

| Plunger diameter | mm | ¢50 ¢60 ¢70 |

| lnjection weight(aluminum) | Kg | 2.8 |

| Casting pressure (intensification) | MPa | 168/116/85 |

| Max. casting area(40Mpa) | CM2 | 680 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 15 |

| Dimensions (L*W*H) | m | 6.4*1.7*2.8 |

| Machine lifting reference weight | T | 12 |

| Oil tank capacity | L | 650 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 3000 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250~650 |

| Space between tie bars | mm | 560*560 |

| Ejector stroke | mm | 100 |

| Ejector force | KN | 110 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 330 |

| Injection stroke | mm | 380 |

| Plunger diameter | mm | ¢50 ¢60¢70 |

| lnjection weight(aluminum) | Kg | 3 |

| Casting pressure (intensification) | MPa | 168/116/85 |

| Max. casting area(40Mpa) | CM2 | 700 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 15 |

| Dimensions (L*W*H) | m | 6.4*1.7*2.8 |

| Machine lifting reference weight | T | 12 |

| Oil tank capacity | L | 650 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 3300 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250~750 |

| Space between tie bars | mm | 600*600 |

| Ejector stroke | mm | 110 |

| Ejector force | KN | 160 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 360 |

| Injection stroke | mm | 480 |

| Plunger diameter | mm | ¢50 --¢80 |

| lnjection weight(aluminum) | Kg | 3.8 |

| Casting pressure (intensification) | MPa | 184/127/96 |

| Max. casting area(40Mpa) | CM2 | 865 |

| Injection plunger penetration | mm | 180 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 18.5 |

| Dimensions (L*W*H) | m | 6.8*1.8*2.7 |

| Machine lifting reference weight | T | 14.5 |

| Oil tank capacity | L | 800 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 3500 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250-750 |

| Space between tie bars | mm | 600*600 |

| Ejector stroke | mm | 110 |

| Ejector force | KN | 160 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 360 |

| Injection stroke | mm | 480 |

| Plunger diameter | mm | ¢50 -- ¢80 |

| lnjection weight(aluminum) | Kg | 3.8 |

| Casting pressure (intensification) | MPa | 184/127/96 |

| Max. casting area(40Mpa) | CM2 | 865 |

| Injection plunger penetration | mm | 180 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 12 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 18.5 |

| Dimensions (L*W*H) | m | 6.8*1.8*2.7 |

| Machine lifting reference weight | T | 14.5 |

| Oil tank capacity | L | 800 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 4000 |

| Opening stroke | mm | 520 |

| Die thickness(Min--Max) | mm | 250-700 |

| Space between tie bars | mm | 620*620 |

| Ejector stroke | mm | 110 |

| Ejector force | KN | 160 |

| Injection position(0 as center) | mm | 0,-175 |

| Injection force(intensification) | KN | 410 |

| Injection stroke | mm | 480 |

| Plunger diameter | mm | ¢60--¢80 |

| lnjection weight(aluminum) | Kg | 4.5 |

| Casting pressure (intensification) | MPa | 145/106/81 |

| Max. casting area(40Mpa) | CM2 | 875 |

| Injection plunger penetration | mm | 180 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 18.5 |

| Dimensions (L*W*H) | m | 6.7*1.9*2.88 |

| Machine lifting reference weight | T | 15 |

| Oil tank capacity | L | 810 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 4500 |

| Opening stroke | mm | 550 |

| Die thickness(Min--Max) | mm | 300~750 |

| Space between tie bars | mm | 660*660 |

| Ejector stroke | mm | 130 |

| Ejector force | KN | 200 |

| Injection position(0 as center) | mm | 0,-175 |

| Injection force(intensification) | KN | 415 |

| Injection stroke | mm | 570 |

| Plunger diameter | mm | ¢60--¢80 |

| lnjection weight(aluminum) | Kg | 4.8 |

| Casting pressure (intensification) | MPa | 148/109/83 |

| Max. casting area(40Mpa) | CM2 | 1000 |

| Injection plunger penetration | mm | 210 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 22 |

| Dimensions (L*W*H) | m | 7*2*2.87 |

| Machine lifting reference weight | T | 16 |

| Oil tank capacity | L | 820 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 5000 |

| Opening stroke | mm | 580 |

| Die thickness(Min--Max) | mm | 320~800 |

| Space between tie bars | mm | 760*660 |

| Ejector stroke | mm | 120 |

| Ejector force | KN | 240 |

| Injection position(0 as center) | mm | 0,-220 |

| Injection force(intensification) | KN | 450 |

| Injection stroke | mm | 580 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 6.9 |

| Casting pressure (intensification) | MPa | 135/117/92 |

| Max. casting area(40Mpa) | CM2 | 1250 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 22 |

| Dimensions (L*W*H) | m | 7.7*2.1*3.1 |

| Machine lifting reference weight | T | 20 |

| Oil tank capacity | L | 1000 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 6300 |

| Opening stroke | mm | 650 |

| Die thickness(Min--Max) | mm | 350~850 |

| Space between tie bars | mm | 750*750 |

| Ejector stroke | mm | 150 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 590 |

| Injection stroke | mm | 600 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 7.2 |

| Casting pressure (intensification) | MPa | 153/117/92 |

| Max. casting area(40Mpa) | CM2 | 1575 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8*2.2*3 |

| Machine lifting reference weight | T | 25 |

| Oil tank capacity | L | 1050 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 6500 |

| Opening stroke | mm | 650 |

| Die thickness(Min--Max) | mm | 350~900 |

| Space between tie bars | mm | 810*810 |

| Ejector stroke | mm | 160 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 590 |

| Injection stroke | mm | 650 |

| Plunger diameter | mm | ¢80 ¢90¢100 |

| lnjection weight(aluminum) | Kg | 10 |

| Casting pressure (intensification) | MPa | 123/79 |

| Max. casting area(40Mpa) | CM2 | 1525 |

| Injection plunger penetration | mm | 280 |

| Diameter of pressure chamber flange | mm | 165 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8*2.1*3.1 |

| Machine lifting reference weight | T | 30 |

| Oil tank capacity | L | 1100 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 7000 |

| Opening stroke | mm | 650 |

| Die thickness(Min--Max) | mm | 350~850 |

| Space between tie bars | mm | 760*760 |

| Ejector stroke | mm | 150 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 590 |

| Injection stroke | mm | 600 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 7.2 |

| Casting pressure (intensification) | MPa | 153/117/92 |

| Max. casting area(40Mpa) | CM2 | 1575 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8*2.2*3 |

| Machine lifting reference weight | T | 25 |

| Oil tank capacity | L | 1050 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 8000 |

| Opening stroke | mm | 760 |

| Die thickness(Min--Max) | mm | 400~950 |

| Space between tie bars | mm | 910*910 |

| Ejector stroke | mm | 180 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 680 |

| Injection stroke | mm | 760 |

| Plunger diameter | mm | ¢80 ¢90 ¢100 |

| lnjection weight(aluminum) | Kg | 11.2 |

| Casting pressure (intensification) | MPa | 135/106/86 |

| Max. casting area(40Mpa) | CM2 | 2000 |

| Injection plunger penetration | mm | 295 |

| Diameter of pressure chamber flange | mm | 200 |

| Height of pressure chamber flange | mm | 20 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8.7*2.5*3 |

| Machine lifting reference weight | T | 38 |

| Oil tank capacity | L | 1300 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 9000 |

| Opening stroke | mm | 800 |

| Die thickness(Min--Max) | mm | 400~1000 |

| Space between tie bars | mm | 960*960 |

| Ejector stroke | mm | 190 |

| Ejector force | KN | 360 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 775 |

| Injection stroke | mm | 760 |

| Plunger diameter | mm | ¢80 -- ¢110 |

| lnjection weight(aluminum) | Kg | 13.5 |

| Casting pressure (intensification) | MPa | 154/121/81 |

| Max. casting area(40Mpa) | CM2 | 2350 |

| Injection plunger penetration | mm | 300 |

| Diameter of pressure chamber flange | mm | 200 |

| Height of pressure chamber flange | mm | 20 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 37 |

| Dimensions (L*W*H) | m | 10*3*3.5 |

| Machine lifting reference weight | T | 45 |

| Oil tank capacity | L | 1500 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 10000 |

| Opening stroke | mm | 880 |

| Die thickness(Min--Max) | mm | 450~1150 |

| Space between tie bars | mm | 1030*1030 |

| Ejector stroke | mm | 200 |

| Ejector force | KN | 500 |

| Injection position(0 as center) | mm | 0,-300 |

| Injection force(intensification) | KN | 882 |

| Injection stroke | mm | 800 |

| Plunger diameter | mm | ¢90----¢120 |

| lnjection weight(aluminum) | Kg | 17 |

| Casting pressure (intensification) | MPa | 138.6/78 |

| Max. casting area(40Mpa) | CM2 | 2500 |

| Injection plunger penetration | mm | 300 |

| Diameter of pressure chamber flange | mm | 240 |

| Height of pressure chamber flange | mm | 20 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 45 |

| Dimensions (L*W*H) | m | 9.3*3.9*4 |

| Machine lifting reference weight | T | 70 |

| Oil tank capacity | L | 2000 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 12500 |

| Opening stroke | mm | 860 |

| Die thickness(Min--Max) | mm | 550~1100 |

| Space between tie bars | mm | 1100*1100 |

| Ejector stroke | mm | 200 |

| Ejector force | KN | 570 |

| Injection position(0 as center) | mm | -160,-320 |

| Injection force(intensification) | KN | 1075 |

| Injection stroke | mm | 880 |

| Plunger diameter | mm | ¢100-¢140 |

| lnjection weight(aluminum) | Kg | 25.4 |

| Casting pressure (intensification) | MPa | 137/70 |

| Max. casting area(40Mpa) | CM2 | 3125 |

| Injection plunger penetration | mm | 320 |

| Diameter of pressure chamber flange | mm | 200 |

| Height of pressure chamber flange | mm | 20 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 30*2 |

| Dimensions (L*W*H) | m | 11.3*4.3*4.5 |

| Machine lifting reference weight | T | 80 |

| Oil tank capacity | L | 3000 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 16000 |

| Opening stroke | mm | 1200 |

| Die thickness(Min--Max) | mm | 500~1400 |

| Space between tie bars | mm | 1250*1250 |

| Ejector stroke | mm | 250 |

| Ejector force | KN | 570 |

| Injection position(0 as center) | mm | -175,-350 |

| Injection force(intensification) | KN | 1298 |

| Injection stroke | mm | 930 |

| Plunger diameter | mm | ¢110-¢150 |

| lnjection weight(aluminum) | Kg | 30.8 |

| Casting pressure (intensification) | MPa | 174/32.3 |

| Max. casting area(40Mpa) | CM2 | 4000 |

| Injection plunger penetration | mm | 360 |

| Diameter of pressure chamber flange | mm | 260 |

| Height of pressure chamber flange | mm | 30 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 37*2 |

| Dimensions (L*W*H) | m | 12.2*4.7*4.6 |

| Machine lifting reference weight | T | 95 |

| Oil tank capacity | L | 3000 |

| ITEMS | Unit | Specification |

| Clamping Force | KN | 20000 |

| Opening stroke | mm | 1400 |

| Die thickness(Min--Max) | mm | 650~1600 |

| Space between tie bars | mm | 1350*1350 |

| Ejector stroke | mm | 300 |

| Ejector force | KN | 650 |

| Injection position(0 as center) | mm | -175,-350 |

| Injection force(intensification) | KN | 1510 |

| Injection stroke | mm | 960 |

| Plunger diameter | mm | ¢130-¢170 |

| lnjection weight(aluminum) | Kg | 40 |

| Casting pressure (intensification) | MPa | 113/66 |

| Max. casting area(40Mpa) | CM2 | 5000 |

| Injection plunger penetration | mm | 400 |

| Diameter of pressure chamber flange | mm | 260 |

| Height of pressure chamber flange | mm | 30 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 55*3 |

| Dimensions (L*W*H) | m | 13.5*4.7*4.8 |

| Machine lifting reference weight | T | 120 |

| Oil tank capacity | L | 3600 |

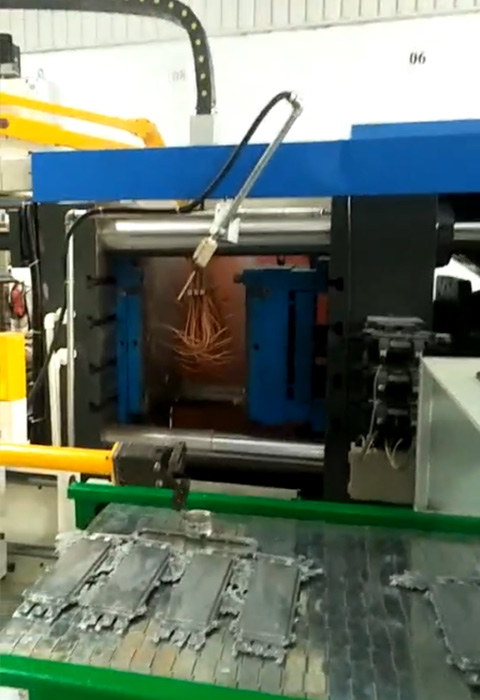

The working steps of the die casting machine are as follows:

(1) Close the mold;

(2) Pour molten metal into the press chamber by manual or automated robotic arm;

(3) The upper punch moves down at a lower injection speed, enters the pressure chamber and just touches the molten metal surface;

(4) The upper punch is turned to a higher injection speed and pressed down, while the lower punch and the upper punch keep the relative distance between the upper punch and the molten metal and move down synchronously;

(5) When the lower punch moves down to let out the nozzle orifice, it just goes down to the bottom and is supported; therefore, the upper and lower punches squeeze the molten metal at high speed to the nozzle hole (part of sprue 6) injection;

(6) The molten metal passes through the sprue 6 composed of the nozzle, the sprue sleeve 4, the tapered hole of the fixed mold and the diverter 2, and fills into the mold cavity from the inner gate 3;

(7) The filling is completed, but the upper punch still maintains a certain pressure until the molten metal in the cavity is completely solidified into the die casting 1; the molten metal in the runner and the pressure chamber solidifies into the sprue and the remaining cake 9 respectively. ;

(8) The upper punch lifts and resets; at the same time, the lower punch moves upwards to cut away the remaining cake that is still connected to the straight gate;

(9) The lower punch continues to rise, lift the remaining cake out of the top surface of the pressure chamber, and then take it away manually or by other means;

(10) Move the lower punch down and reset to block the nozzle orifice;

(11) Open the mold, the die-casting part and the straight gate stay on the movable mold together, and then eject and take out the die-casting part; once the remaining cake is cut away, the mold opening action can be executed immediately, or it can be slightly slowed to an appropriate time Execution has nothing to do with the lifting and resetting of the lower punch; at this point, a die-casting cycle is completed.

Customer satisfaction is our eternal pursuit, longhua always pay attention to customer needs, in order to reduce customer mechanical failure time, longhua service center after ten years precipitation a set of perfect server process, with the fastest response cycle for customers to repair machines, improve customer machine operating rate.