EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

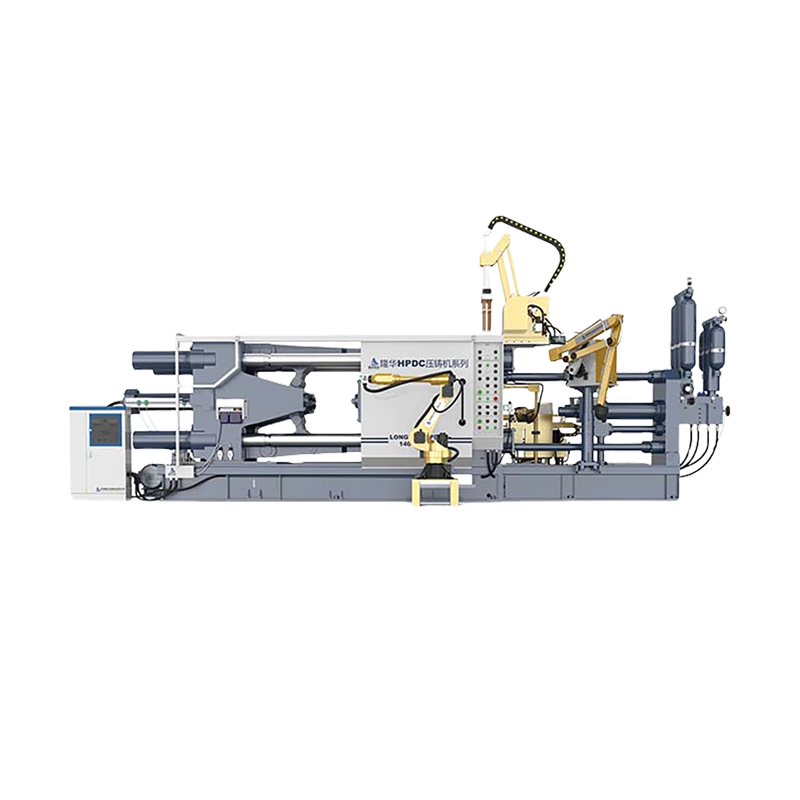

In modern manufacturing, precision, speed, and cost-efficiency are key drivers in the choice of casting methods. A hot chamber die casting machine offers all these benefits, making it a popular choice for producing high-volume, small-to-medium-sized parts with low-melting point alloys. This article will explain the working process of a hot chamber die casting machine, its core components, advantages, limitations, and its applications.

A hot chamber die casting machine is a specialized machine used in manufacturing processes that involve injecting molten metal into a die cavity under high pressure. The key feature of this system is its internal melting chamber, where the metal is kept molten until it is injected into the die. This contrasts with cold chamber die casting machines, where the molten metal is poured into the injection chamber from an external furnace.

Hot chamber die casting is typically used for materials with lower melting points, such as zinc, magnesium, and lead/tin alloys. This machine is designed for high-volume production, making it ideal for industries that require consistent, large quantities of parts.

The hot chamber die casting machine consists of several essential components that work together to produce high-quality castings:

Melting Furnace: The molten metal is stored in the machine’s internal furnace, which keeps the metal at the desired temperature.

Gooseneck (or Shot Tube): This is the conduit that transfers the molten metal from the furnace to the die. It is often made of durable materials to withstand the extreme temperatures.

Nozzle: This part of the system directs the molten metal into the die cavity. It is connected to the gooseneck and is carefully designed to ensure smooth flow.

Hydraulic Plunger/Piston: This is the mechanism that forces the molten metal into the die cavity under high pressure, ensuring a precise fill.

Die: The die is the mold that gives the part its shape. It consists of two halves – the fixed half and the movable half – that are clamped together during the injection process.

Understanding the detailed steps of how a hot chamber die casting machine operates will provide clarity on its efficiency and capabilities. The process includes the following stages:

Melting the Metal: The metal is heated in the internal furnace of the machine and maintained at the correct molten state. This ensures that the injection process will occur smoothly.

Die Clamping: Once the die is in place, the two halves of the mold are closed securely, preparing for the injection of molten metal.

Injection: The hydraulic plunger forces the molten metal from the furnace into the gooseneck and through the nozzle into the die. This high-pressure injection fills the cavity completely, ensuring high precision.

Holding Pressure and Solidification: As the molten metal fills the cavity, pressure is maintained to keep the metal in place and ensure solidification. The cooling process begins almost immediately.

Die Opening and Ejection: After the metal solidifies, the die is opened, and the casting is ejected from the mold. The part is ready for trimming and further processing if necessary.

Recycling and Repeat: The machine is ready to begin the next cycle, making it a highly efficient and fast process for mass production.

The hot chamber die casting machine offers several significant advantages:

Fast Cycle Times: The molten metal is already inside the machine, which eliminates the need to transfer molten metal from an external furnace, speeding up the overall process.

High Precision: The high pressure and efficient injection process result in parts with excellent dimensional accuracy and a smooth surface finish.

Reduced Material Waste: Less handling of molten metal means less chance for spillage and material waste.

High Production Rates: This machine is designed for high-volume production, making it ideal for producing large quantities of parts quickly and cost-effectively.

While the hot chamber die casting machine offers many benefits, it does come with certain limitations:

Limited Material Use: The process is generally limited to low-melting-point alloys like zinc, magnesium, and lead/tin. It is not suitable for high-melting-point metals such as aluminum or copper.

Size and Weight Constraints: Hot chamber die casting machines are better suited for producing smaller to medium-sized parts. Large parts may not be suitable for this process due to the limitations of the machine’s size.

Wear and Tear: The gooseneck, nozzle, and other components exposed to high temperatures can wear out over time and require maintenance or replacement.

High Initial Investment: While the machine offers rapid production speeds, the initial investment in equipment and tooling can be significant.

The hot chamber die casting machine is designed primarily for alloys with lower melting points. The most common materials used are:

Zinc Alloys: The most frequently used material due to its low melting point, excellent casting properties, and versatility.

Magnesium Alloys: These are used for lightweight parts, especially in the automotive and aerospace industries.

Lead/Tin Alloys: Commonly used in specialized applications where corrosion resistance is important.

However, it is not suitable for high-melting-point materials such as aluminum or copper, which require a cold chamber die casting machine.

The hot chamber die casting machine is widely used across various industries due to its efficiency and precision. Some common applications include:

Automotive: Small components such as gearbox housings, levers, and fittings.

Electronics: Enclosures and connectors for electrical devices.

Consumer Goods: Manufacturing parts that require high precision and are produced in large quantities.

Hardware: Small fittings, fasteners, and components used in tools and machinery.

The hot chamber die casting machine is ideal for certain materials, but a cold chamber die casting machine may be a better choice for high-melting-point alloys like aluminum. Here are the key differences:

Hot Chamber: Faster cycle times, better suited for low-melting alloys like zinc, magnesium, and lead.

Cold Chamber: Slower cycle times, better suited for high-melting alloys like aluminum.

Choosing between these two methods depends on the material being used, the size of the part, and the production volume.

When selecting a hot chamber die casting machine, it is important to consider the following:

Machine Tonnage: Ensure the machine has the appropriate clamp force for your part size and material.

Injection System: Evaluate the nozzle design, injection speed, and temperature control capabilities.

Maintenance Requirements: Be prepared for the maintenance of components that experience wear, such as the gooseneck and nozzle.

Production Volume: This process is ideal for high-volume production. Ensure your machine can handle the expected production rate.

Tooling and Die Design: Consider the material and design of your dies to ensure compatibility with the hot chamber process.

What alloys can be used in a hot chamber die casting machine?

Zinc, magnesium, and lead/tin alloys are the most commonly used.

Why can't I die-cast aluminum in a hot chamber machine?

Aluminum has a high melting point that exceeds the limits of the hot chamber system, requiring a cold chamber die casting machine.

What is the typical cycle time for a hot chamber die casting machine?

Cycle times can range from a few seconds to a minute, depending on the complexity and size of the part.

What are the maintenance concerns for a hot chamber die casting machine?

Components exposed to molten metal, such as the gooseneck and nozzle, will wear out over time and need to be replaced regularly.

The hot chamber die casting machine is a powerful tool for high-precision, high-volume production of parts using low-melting-point alloys. Its speed, efficiency, and ability to deliver consistent results make it a popular choice in industries such as automotive, electronics, and consumer goods manufacturing. However, it is important to consider the material compatibility, part size, and maintenance needs when selecting the right machine for your business.