EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

The price of a hot chamber die casting machine is determined by several factors that influence the overall cost, making it important for manufacturers and businesses to understand these elements when making a purchase. In this article, we will explore the various factors that influence the price of hot chamber die casting machines and what to consider when investing in these essential pieces of equipment for die casting processes.

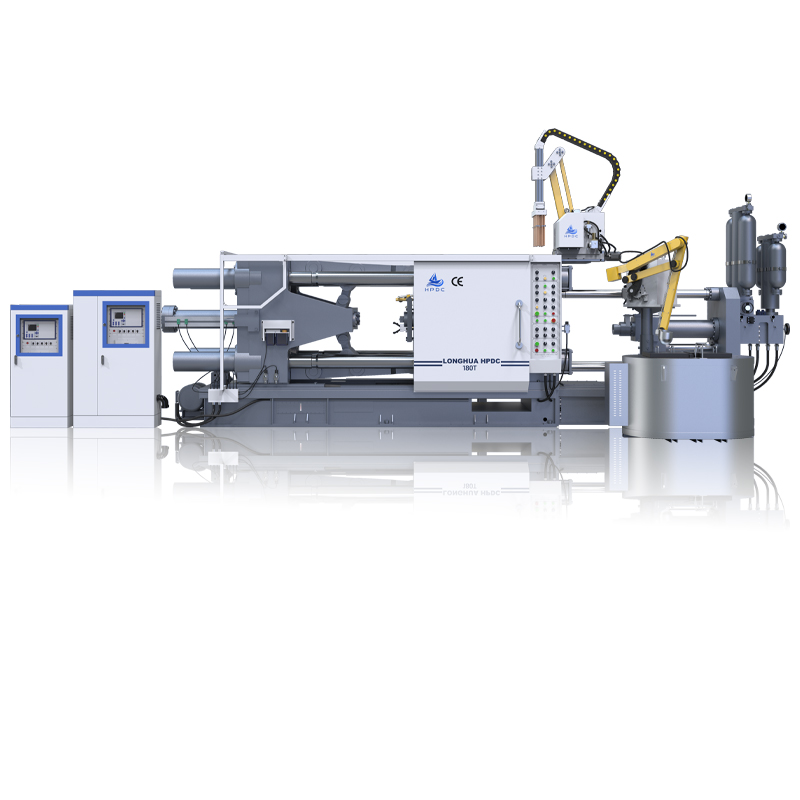

A hot chamber die casting machine is a specialized piece of equipment used in the manufacturing process to cast metal into predefined molds under high pressure. It is particularly used for metals with low melting points, such as zinc, magnesium, and aluminum alloys. These machines offer high precision, efficiency, and fast production cycles, making them ideal for producing large volumes of small, complex parts.

The machine works by melting the metal in a heated chamber and then forcing the molten metal into a mold under pressure, creating parts that are highly detailed and precise. Hot chamber machines are typically faster than cold chamber machines, making them more suitable for high-volume production.

Several factors contribute to the pricing of hot chamber die casting machines, ranging from machine size and capacity to the level of automation and customization. Understanding these elements can help businesses make more informed purchasing decisions.

The size of the machine plays a significant role in determining its price. Larger machines designed to handle bigger molds and higher production volumes come with a higher price tag. The capacity of the machine to handle varying volumes of metal and different mold sizes directly impacts its cost, as more powerful machines require more complex engineering and larger components.

The materials used in constructing the die casting machine are essential to its durability, efficiency, and cost. High-quality materials, such as hardened steel and alloys, increase the machine's price due to their enhanced performance and longevity. Moreover, machines designed for specific industries or applications may require special materials that further drive up the cost.

Modern hot chamber die casting machines often come equipped with advanced automation, robotics, and precision control systems. These features are designed to improve the machine's efficiency and reduce the need for manual labor. Machines with high-tech features such as automated feeding systems, precise temperature control, and real-time monitoring capabilities typically come at a premium price. The addition of digital integration and smart technology further raises the machine's cost but offers increased productivity and reduced downtime.

Machines that offer high efficiency in terms of production speed and cycle time are often more expensive. Shorter cycle times mean higher output, which is crucial in high-demand industries. Machines that can produce parts faster while maintaining precision tend to have a higher price, but they provide a better return on investment due to their increased production capacity.

The reputation of the manufacturer and the brand name also play a significant role in the pricing of hot chamber die casting machines. Established manufacturers with a history of producing high-quality machines generally charge higher prices. This is because customers are paying for the reliability, support, and warranty services that come with a reputable brand. Leading brands often offer better after-sales service, making them a preferred choice despite the higher upfront cost.

Customization is another factor that influences the price. Some businesses may need machines tailored to their specific production needs, such as unique mold designs, additional cooling systems, or multi-material capabilities. Customizing a machine to suit unique requirements adds to the overall cost, but it can be a worthwhile investment if it significantly enhances production quality and efficiency.

Economic conditions, supply chain disruptions, and demand in various industries also impact the cost of hot chamber die casting machines. For instance, periods of high demand for die-cast products or metal alloys can drive up prices due to material shortages and increased competition for resources. Manufacturers need to account for global market conditions when estimating the cost of acquiring these machines.

Due to their size and complexity, hot chamber die casting machines require significant shipping and installation efforts. Depending on the location of the buyer and the machine's manufacturer, shipping costs can add a substantial amount to the overall price. Additionally, the complexity of installing and calibrating the machine can also incur extra costs for professional services.

Calculating the cost of a hot chamber die casting machine involves factoring in several key variables, such as machine size, features, and the cost of installation and maintenance. A basic cost estimation formula might include:

Base Machine Cost: The initial price of the machine, depending on its size, automation level, and features.

Customization Costs: If the machine needs any customization, these additional costs must be considered.

Operational Costs: Includes energy consumption, maintenance, and parts replacement.

Shipping and Installation Costs: The costs associated with transporting and setting up the machine at the business location.

By considering these factors, businesses can get a more accurate idea of the total cost of owning and operating a hot chamber die casting machine.

Global market trends and technological advancements are key contributors to the fluctuation in prices. As the demand for aluminum and other die-casting materials increases, prices for machines capable of handling these materials may rise as well. Technological advancements, such as the development of faster and more efficient casting processes, can also influence machine prices. Additionally, the rise of eco-friendly manufacturing processes may push manufacturers to develop more sustainable machines, which could lead to higher costs.

RapidDirect: RapidDirect emphasizes that the price of hot chamber die casting machines is closely linked to the machine's productivity. The more efficient the machine, the higher the cost, but the greater the return on investment.

UnityManufacture: UnityManufacture highlights the importance of machine size and complexity in determining price. Machines with specialized features for unique applications typically cost more.

Haichen DCM: Haichen DCM points out that automation is one of the major contributors to higher machine costs. Machines with advanced robotics and automated systems can significantly reduce labor costs and improve production efficiency.

Casting-YZ: Casting-YZ notes that the material used in the construction of the machine is critical to its durability and efficiency, which influences the cost. The use of high-quality materials raises the price but ensures longer machine life and lower maintenance costs.

CastingOD: CastingOD discusses how different die casting machines are priced based on the capabilities they offer. Machines designed for high-volume, high-precision manufacturing typically come at a premium.

The price of a hot chamber die casting machine is influenced by various factors, including machine size, automation features, material quality, and market conditions. Understanding these factors can help businesses make more informed decisions when investing in these machines. By considering both the upfront costs and the long-term operational efficiency, businesses can find the right machine that offers the best value for their production needs.