EMAIL:

sales@longhuamachine.com

TELL/whatsapp:

+86-18905522221  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

You cannot use metals like iron, steel, or titanium in a cold chamber die casting machine. These metals have high melting points that can damage the equipment and cause safety risks during the cold chamber die casting process. In cold chamber die-casting, you face problems such as increased machine wear, casting defects, and longer cycle times. The cold chamber die method works best for metals with lower melting points. If you try to use iron or steel in cold chamber die-casting, you risk equipment failure and poor results. You should consider other casting methods for these metals.

Cold chamber die casting works best for metals like aluminum, magnesium, and copper alloys with melting points below about 1,100°C.

Metals such as iron, steel, and titanium have very high melting points and poor flow, making them unsuitable for cold chamber die casting.

Using wrong metals can damage the machine, cause casting defects, and create safety hazards like toxic fumes and equipment failure.

Alternative casting methods like sand casting and investment casting are better choices for high-melting-point metals like iron and titanium.

Always check metal properties and match them to the casting process to ensure quality parts, protect equipment, and maintain safe operations.

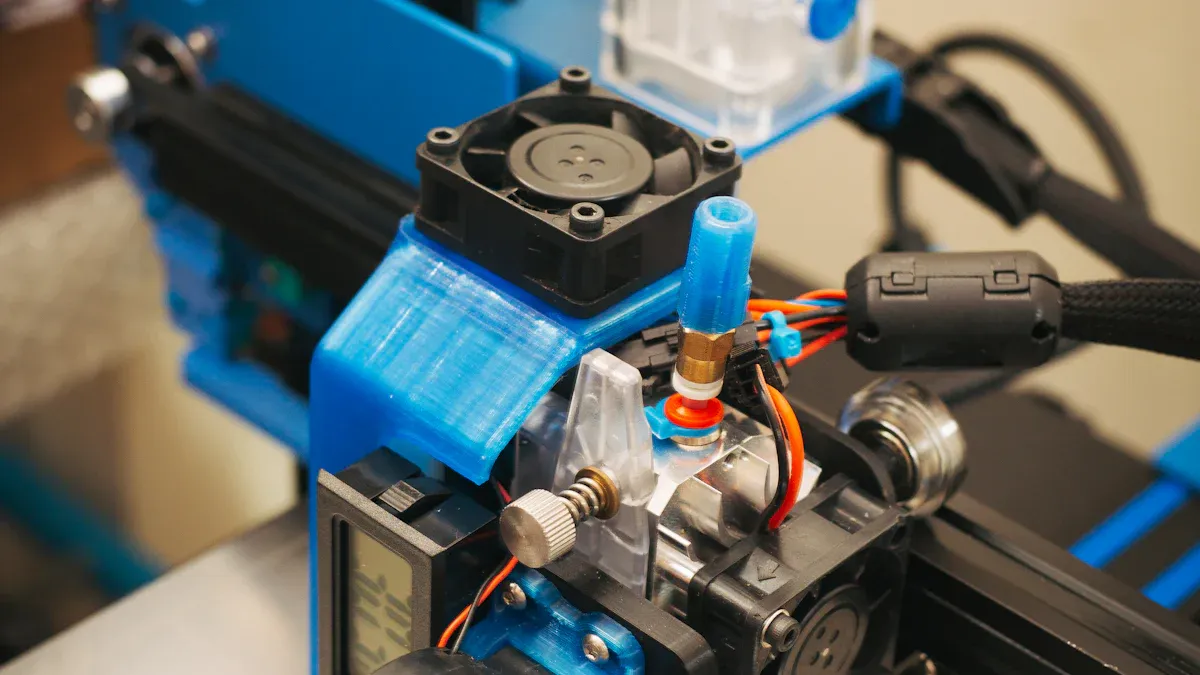

You use the cold chamber die casting process when you need to cast metals with higher melting points. This process keeps the molten metal outside the cold chamber die casting machine until you are ready to inject it. You first build the die and mold tooling system, making sure the runners and gates guide the molten metal into the cold chamber die. You then prepare the components of a cold chamber die casting machine, including the hydraulic piston, molten metal chamber, and clamping units. You align the die and test the flow before heating the machine.

Here are the main steps in the cold chamber die-casting process:

Make the die casting tooling system with runners and gates for accuracy.

Prepare the cold chamber die casting machine and align the die.

Choose the right material, such as aluminum, magnesium, or copper alloys, and melt it in an external furnace.

Pour molten metal into the cold chamber, then inject it under high pressure into the die cavity.

Allow the metal to cool and solidify inside the cold chamber die.

Perform post die casting operations like trimming, deburring, and surface treatments.

The cold chamber die casting process uses high pressure to fill the die cavity quickly. You get parts with smooth surfaces and precise dimensions. The cold chamber die-casting method differs from hot chamber die casting because the molten metal stays outside the machine until injection. This process works best for metals that need higher temperatures.

Tip: Cold chamber die-casting takes longer than hot chamber die casting, but it handles metals with higher melting points.

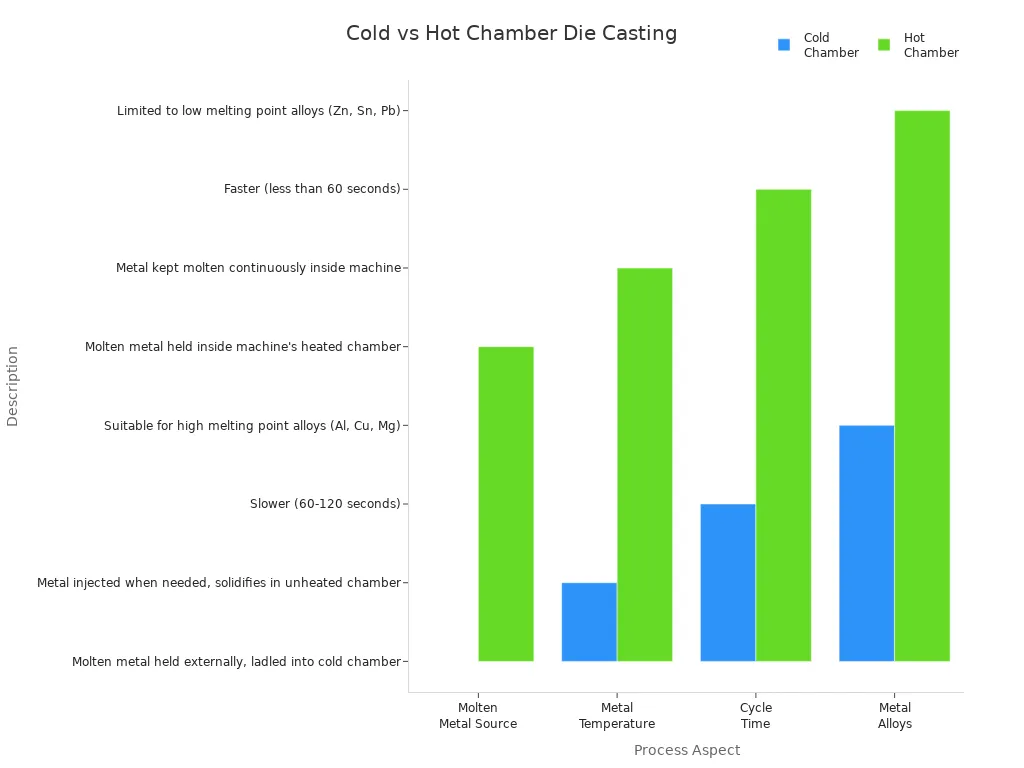

Here is a table comparing cold chamber die casting and hot chamber die casting:

Aspect | Cold Chamber Die Casting | Hot Chamber Die Casting |

|---|---|---|

Molten Metal Source | Molten metal held externally, ladled into cold chamber | Molten metal held inside machine's heated chamber |

Metal Temperature | Metal injected when needed, solidifies in unheated chamber | Metal kept molten continuously inside machine |

Cycle Time | Slower (60-120 seconds) | Faster (less than 60 seconds) |

Metal Alloys | Suitable for high melting point alloys (Al, Cu, Mg) | Limited to low melting point alloys (Zn, Sn, Pb) |

You should use metals with higher melting points in the cold chamber die-casting process. The most common metals for cold chamber die-casting are aluminum, magnesium alloys, copper alloys, and zinc alloys with high aluminum content. These metals work well because the cold chamber die casting machine uses an external furnace, which gives you better temperature control.

Aluminum is popular for aluminum die casting because it is lightweight and strong.

Magnesium alloys are even lighter and used when you need low weight.

Copper alloys offer excellent electrical conductivity.

Zinc alloys with high aluminum content are used selectively in cold chamber die-casting.

The cold chamber die casting process is ideal for metals with melting points above 600°C. You get strong, precise parts with good surface finish when you use the right metals in the cold chamber die-casting process. The components of a cold chamber die casting machine help you achieve these results by handling high temperatures and pressures.

When you choose metals for cold chamber die casting, you must consider several important factors. Not every metal works well in the cold chamber die casting process. Some metals create serious problems for your cold chamber die, leading to poor results and even equipment damage. Let’s look at the main reasons why metals like iron, steel, and titanium cannot be used in cold chamber die-casting.

You face major challenges when you try to use metals with very high melting points in cold chamber die-casting. Iron, steel, and titanium all melt at temperatures much higher than aluminum, copper, or magnesium alloys. For example, zinc alloys melt around 385°C, which is perfect for hot chamber die casting. Aluminum and copper alloys have higher melting points, so you use the cold chamber die casting process for them. However, iron and steel melt at temperatures above 1,400°C. Your cold chamber die cannot handle these extreme temperatures. The die-casting machine and tooling will wear out quickly or even fail. You risk damaging the cold chamber die and creating unsafe working conditions.

Note: If you try to cast iron or steel in a cold chamber die, you will likely destroy the die and the casting machine. Always check the melting point before you select a metal for cold chamber die-casting.

Here is a table showing melting points for common metals:

Metal | Melting Point (°C) | Suitable for Cold Chamber Die-Casting? |

|---|---|---|

Zinc | ~385 | Yes |

Magnesium | ~650 | Yes |

Aluminum | ~660 | Yes |

Copper | ~1,085 | Yes |

Iron | ~1,538 | No |

Steel | ~1,370-1,540 | No |

Titanium | ~1,668 | No |

Some metals react strongly with the materials used in cold chamber die-casting. Titanium and certain steel alloys can corrode or bond with the cold chamber die surface. You will see rapid wear, pitting, and even chemical reactions that ruin the die. These metals may also react with lubricants or release harmful gases during casting. Your cold chamber die casting machine cannot safely process these reactive metals. You must avoid using metals that corrode or react with the die-casting environment.

Tip: Always check the chemical properties of your metal before you use it in cold chamber die-casting. Reactive metals can shorten the life of your cold chamber die and increase maintenance costs.

Successful cold chamber die-casting depends on how well the molten metal flows into the die. You need steady, laminar flow and proper fusion of the metal fronts. Metals like iron and titanium do not flow easily at casting temperatures. They have poor fluidity, which leads to defects such as cold shuts, shrinkage, and incomplete fusion. Your cold chamber die casting machine needs precise control of pouring temperature and mold temperature. If the metal does not flow well, you will see incomplete filling, porosity, and weak castings.

You must use metals with good fluidity for cold chamber die-casting.

Poor flow causes defects and reduces the quality of your cast parts.

Metals with high impurity content or improper alloy composition also fail to meet flow criteria.

Callout: If you notice cold shuts or incomplete fusion in your castings, check the flow characteristics of your metal. Metals with poor fluidity are not suitable for cold chamber die-casting.

Here are some flow requirements for cold chamber die-casting:

Proper pouring temperature and mold temperature.

Correct runner and gating system design.

Adequate filling speed to prevent cold shuts.

Steady, laminar flow to avoid turbulence.

Good exhaust and venting to prevent gas entrapment.

Metals that do not meet these requirements will not produce strong, reliable castings in a cold chamber die. You should always select metals with proven flow characteristics for the cold chamber die casting process.

When you use a cold chamber die casting machine with unsuitable metals, you face several technical failures. The cold chamber die cannot handle metals with high melting points or poor flow properties. If you try to cast iron, steel, or titanium, you will see defects in your castings. These problems include cold flow, shrinkage cavities, blisters, and soldering points. Each defect results from the metal’s properties or incorrect process parameters.

Here is a table showing common technical failures in cold chamber die-casting:

Defect Name | Description | Causes Related to Unsuitable Metal Properties or Process Parameters |

|---|---|---|

Cold Flow | Premature solidification of two melt fronts during die filling, resulting in poor bonding and scar-like surface defects. | Low melt or die temperature, slow die filling speed, poor die ventilation, incorrect release agent application, unfavorable runner/sprue design. |

Shrinkage Cavity | Irregular cavities inside or on the surface due to volume contraction during solidification. | Low melt or die temperature, slow die filling, alloy composition issues, insufficient holding pressure (e.g., hydraulic defects), plunger jamming. |

Blister | Bulging cavities on the surface caused by trapped gas pores expanding after die opening. | Excessive process chemicals, residual moisture, inadequate die ventilation, low shot sleeve filling, slow casting velocity, too warm melt or die surface. |

Soldering Points | Rough surface areas caused by liquid metal bonding to the die surface due to defective release agent film. | Inhomogeneous or missing release agent, high local melt flow velocity, high solid particle content, hot spots on die surface, poor cooling, too hot melt. |

You must select metals that match the temperature and flow limits of your cold chamber die. If you ignore these barriers, you will waste time and resources on defective castings.

Using the wrong metals in a cold chamber die casting machine creates serious safety hazards. High-melting-point or reactive metals can damage your equipment and put you at risk. You may face the following dangers:

Exposure to toxic fumes and vapors that harm your health.

Explosions or fires if the metal reacts with air or moisture.

Burns from molten metal splashes.

Electrical shocks from faulty equipment.

Chemical spills during casting operations.

These risks increase when you work with high temperatures and pressures in cold chamber die-casting. You must always use proper personal protective equipment (PPE), ensure good ventilation, and train operators to handle emergencies. The cold chamber die cannot protect you from all hazards if you use metals outside its design limits.

Note: Always check the compatibility of your metal with the cold chamber die casting machine. Ignoring safety protocols can lead to severe accidents and equipment failure.

The cold chamber die casting process works best with metals like aluminum, magnesium, and copper alloys. If you use metals with unsuitable properties, you risk technical failures, safety hazards, and costly downtime. You should always match your casting metal to the capabilities of your cold chamber die and machine.

When you cannot use the die-casting process for metals like iron, steel, or titanium, you have several alternative casting methods. Each method offers unique advantages and limitations. You should choose the casting process that matches your metal’s properties and your production needs.

Sand casting uses sand molds to shape molten metal. You can use this casting process for high-melting-point metals such as iron and steel. Sand casting works well for large parts and small production runs. The main advantages include low tooling costs and the ability to recycle sand. You can cast almost any metal, making sand casting very flexible. However, sand casting produces rougher surfaces and less precise dimensions than die-casting. You may need extra machining to achieve tight tolerances.

Aspect | Sand Casting | Cold Chamber Die Casting |

|---|---|---|

Initial Cost | Low tooling and setup costs | High initial tooling costs due to complex dies |

Production Rate | Lower production rates, longer cycle times | Higher production rates, shorter cycle times (than sand casting) |

Precision | Moderate tolerances, less precise | High precision with tight tolerances (<0.1 mm) |

Material Suitability | Versatile, can handle high melting point metals | Specifically used for high melting point metals like aluminum, brass, copper |

Cost Efficiency | More cost-effective for small to medium runs | More economical for large volume production despite higher initial costs |

Tip: Sand casting is ideal when you need flexibility and low cost, but it cannot match the precision or speed of die-casting.

Investment casting, also called lost-wax casting, uses wax patterns and ceramic molds. You can use this casting process for complex shapes and hard alloys, including stainless steel and titanium. The main advantages include excellent surface finish and the ability to create thin walls and detailed features. Investment casting achieves precise tolerances, often better than die-casting. However, the process takes longer and costs more due to the need for new wax patterns and ceramic molds for each cycle.

Casting Method | Typical Tolerance | Surface Finish Quality | Additional Notes |

|---|---|---|---|

Investment Casting | Precise tolerance IT5-6 | Superior surface finish (~125 microinch) | Minimal secondary machining needed; complex shapes achievable |

Cold Chamber Die Casting | Good tolerances (less tight than investment casting) | Good surface finish but usually requires more machining | High-pressure injection; suited for high-volume production |

Investment casting gives you smooth surfaces and accurate dimensions, reducing the need for extra machining.

You can also consider other casting methods for metals that cannot be die-cast. Centrifugal casting uses rotational force to create dense, round parts, such as rings and pipes. Gravity die casting uses permanent metal molds and gravity to fill the mold, offering better surface quality than sand casting. Metal injection casting combines powder metallurgy and casting for small, complex parts, especially in medical or dental applications. Each casting process has its own advantages and limitations. You should consider factors such as part size, shape, production volume, and required properties.

Turbulence during pouring can cause defects.

Fluidity of molten metal affects mold filling.

Shrinkage during cooling may require special mold design.

When you compare these methods to die-casting, you see that the advantages of cold chamber die casting include high production rates, tight tolerances, and good surface finish for suitable metals. However, for metals with high melting points or reactivity, alternative casting processes offer better results and safety.

You need to match each metal to the right casting process. Cold chamber die casting works best for metals with high melting points and corrosion resistance, but not for iron, steel, or titanium. If you use the wrong metal, you risk equipment damage and poor results. Always check metal properties, production volume, and part design before choosing a casting method. The table below highlights key differences:

Casting Method | Suitable Metals | Advantages for Manufacturers |

|---|---|---|

Cold Chamber Die Casting | Aluminum, brass, copper | Handles high melting points, complex alloys |

Hot Chamber Die Casting | Zinc, magnesium, lead | Fast cycles, efficient for low melting point metals |

Alternatives (Sand, Investment) | Iron, steel, titanium | Flexible, good for complex shapes or small batches |

Tip: Consider sand or investment casting for metals that cannot be die-cast. This ensures quality and safety in your manufacturing process.

You should avoid iron, steel, and titanium in a cold chamber die casting machine. These metals have high melting points and poor flow, which can damage your equipment and cause casting defects.

You cannot use cold chamber die casting for stainless steel. Stainless steel melts at very high temperatures. The cold chamber die casting machine cannot handle these conditions safely or efficiently.

Cold chamber die casting uses an external furnace for melting metals like aluminum and copper. Hot chamber die casting keeps the molten metal inside the machine and works best for zinc and magnesium alloys.

Tip: Choose cold chamber casting for metals with higher melting points.

You can use sand casting, investment casting, or gravity die casting for metals like iron, steel, or titanium. These methods work well for high-melting-point metals and complex shapes.

The cold chamber die casting machine needs metals with good fluidity and melting points below its design limits. Using the wrong metal can cause equipment failure, safety risks, and poor-quality castings.