EMAIL:

sales@longhuamachine.com

TELL/whatsapp:

+86-18905522221  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

You can expect a cold chamber die casting machine to cost anywhere from $10,000 to $20,000 for small models with clamping forces between 30 and 150 tons. Larger machines for automotive or industrial applications will cost more, especially as tonnage and automation levels increase. Features like servo energy-saving systems, advanced control panels, and high-quality hydraulic components add value but also raise the price. Understanding how the cold chamber die casting process works—using external melting and high-pressure injection—helps you see why machines designed for precise, high-strength castings carry higher costs.

Cold chamber die casting machines cost between $10,000 and over $1,600,000 depending on size, tonnage, and features.

Higher tonnage machines handle bigger parts and higher pressures but cost more upfront and offer better production capacity.

Automation and advanced control systems increase machine price but improve efficiency, quality, and reduce labor costs.

Choosing the right machine size and features based on your production needs helps balance initial cost with long-term savings.

Comparing quotes, checking included equipment, and planning your budget carefully ensures you get the best value and support.

When you look for a cold chamber die casting machine, you will see a wide range of prices. Entry-level machines cost much less than advanced models. Entry-level machines work well for small production runs or prototyping. These machines often have a clamping force below 100 tons. You can find prices starting at $10,000 and going up to $25,000. For example, Foshan Tejin offers basic models for about $10,000. Ningbo Dongfang sells a 38-ton machine for $15,000 to $17,500.

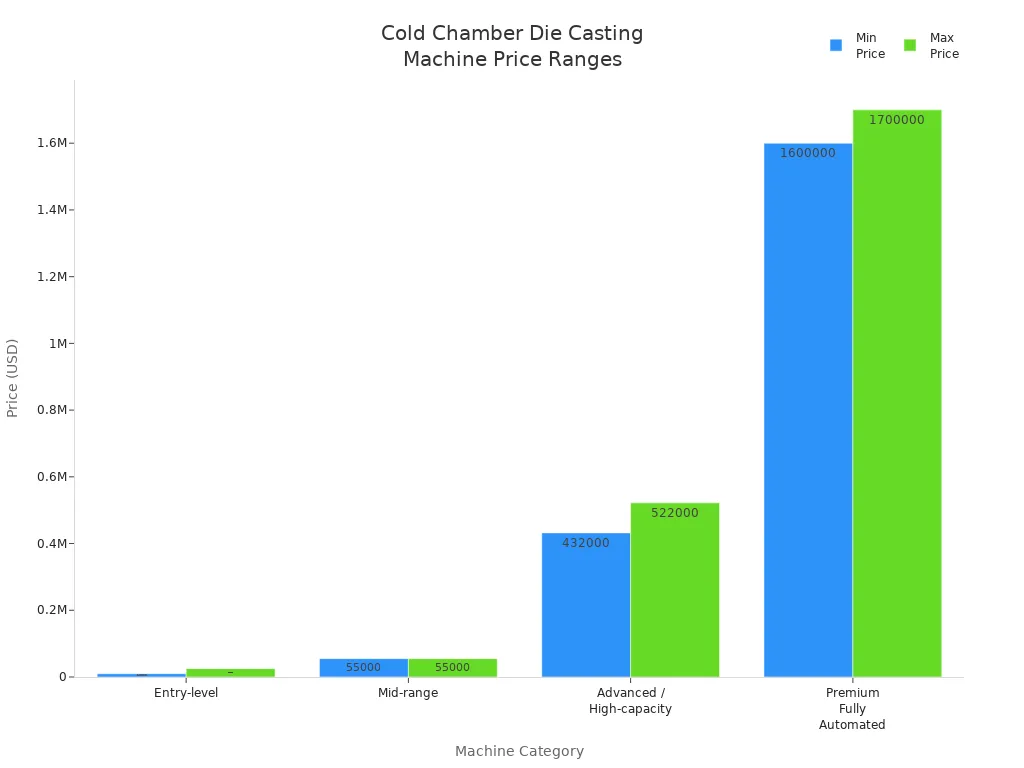

As you move to mid-range machines, the price increases. A 300-ton machine from Jiangmen Zhenli Machinery costs around $55,000. Advanced or high-capacity machines, which you often see in automotive or aerospace factories, have much higher prices. Machines with 1600 to 2000 tons of clamping force can cost between $432,000 and $522,000. If you need a premium, fully automated system with integrated quality control, the price can reach $1,600,000 or more.

Here is a table that shows the price differences between entry-level and advanced cold chamber die casting machines:

Machine Category | Clamping Force (tons) | Price Range (USD) | Example Manufacturer(s) |

|---|---|---|---|

Entry-level | < 100 | $10,000 - $25,000 | Foshan Tejin, Ningbo Dongfang |

Mid-range | ~300 | Around $55,000 | Jiangmen Zhenli Machinery |

Advanced / High-capacity | 1600 - 2000 | $432,000 - $522,000 | Jiangmen Zhenli, Bengbu Longhua |

Premium Fully Automated | 2000+ | $1,600,000 - $1,700,000 | High-end automated systems |

Tip: Entry-level machines suit small businesses or those new to cold chamber die casting. Advanced machines fit large-scale production and industries with strict quality needs.

You can also see the price spectrum in this chart:

The price of a cold chamber die casting machine depends a lot on its tonnage and size. Tonnage means the locking force that keeps the mold closed during injection. If you need to make bigger or more complex parts, you need a machine with higher tonnage. Higher tonnage machines cost more because they have stronger frames, bigger pressure chambers, and advanced control systems.

Here is a table with real-world examples of machines by size and price:

Machine Model / Brand | Capacity (KW) | Tonnage / Force (KN) | Origin | Price (USD) |

|---|---|---|---|---|

Very small machine (30T) | 28 KW | N/A | China | $2,000 |

Small capacity machine | ~18.5 KW | N/A | China | $40,000 - $83,000 |

800T model | N/A | 8000 KN | China | $75,280 |

HAITIAN HDC700-SF | 68.26 KW | N/A | China | $111,700 |

TOYO BD-350V7EX | 40 KW | N/A | Japan | $173,100 |

TOYO BD-1250V7EX | N/A | N/A | Japan | $488,873 |

SHIBAURA DC1100R-E | 150 KVA | N/A | Japan | $975,518 |

You will notice that prices rise as the machine’s tonnage and capacity increase. Machines from China often cost less than those from Japan, especially for larger models. For example, a very small 30-ton machine from China can cost as little as $2,000. A large, high-capacity machine from Japan can reach almost $1 million.

The tonnage rating tells you how much force the machine can use to keep the mold closed. This is important for making sure the mold does not open during the high-pressure injection of molten metal.

Machines with higher tonnage can handle larger parts and higher injection pressures. These machines often include advanced features like servo-hydraulic systems and real-time process control.

If you choose a higher tonnage machine, you pay more, but you also get better production capacity and energy efficiency.

Smaller machines cost less and work well for less demanding jobs. Larger machines cost more but give you more options for complex or large-scale die casting.

Note: The demand for aluminum and magnesium parts in industries like automotive and aerospace pushes companies to invest in high-tonnage, advanced cold chamber die casting machines.

When you select a machine, think about your production needs. If you only need to make small parts, a lower-tonnage machine will save you money. If you plan to produce large or complex parts, you will need a machine with higher tonnage and more advanced features.

When you compare prices for a cold chamber die casting machine, you need to look at several important factors. The design and process requirements for cold chamber die casting make these machines more complex and expensive than other types. Let’s break down the main cost drivers so you can make a smart decision.

The size and tonnage of your machine play a huge role in its price. If you want to cast larger parts, you need a machine with higher clamping force. This force keeps the mold cavity closed while molten metal is injected at high pressure. Bigger machines have stronger frames and larger pressure chambers, which increases their cost.

Machines with higher tonnage handle more molten metal and withstand greater injection pressures.

The pressure chamber must be robust to manage the force needed for cold chamber die casting.

If you choose a machine for aluminum or other metals with high melting points, you need even more strength and durability.

The design must support external melting and ladling, which adds complexity and expense.

Note: Cold chamber die casting uses external melting. You ladle molten metal into the pressure chamber before each cycle. This process takes more time and requires extra equipment, which raises the price compared to hot chamber machines.

Automation can change the cost of your cold chamber die casting machine. If you add robotics, automated ladling, or advanced control systems, you pay more upfront. These features help you run faster cycles, reduce labor costs, and improve consistency.

Automated systems control the injection of molten metal into the pressure chamber.

Robotics can handle ladling, mold release, and part removal, making your process more efficient.

Industry 4.0 features, like IoT monitoring and AI-based process control, increase the initial investment but can lower your long-term costs by reducing downtime and improving quality.

Tip: If you plan to produce high volumes or need precise control, automation pays off over time. You spend more at first, but you save money with fewer errors and lower labor costs.

The brand and features you choose also affect the price. Well-known brands offer machines with advanced pressure chamber designs, reliable hydraulic systems, and safety features. These machines often last longer and require less maintenance.

Brand | Approximate Price (Rs) | Standard Features | Optional Features | Pricing Impact |

|---|---|---|---|---|

EVERGREAT | ~1,00,000 per piece | Hydraulic system, automatic lubricator, piston-type accumulator, safety door | Two injection centers, automatic tie bar pull-out, multi-stage injection control, energy-saving hydraulic device, electric injection valve | Baseline price for new machines; advanced options increase cost |

PRODUCER | ~1,00,000 per piece | Automation, control features, operator-friendly interface | N/A | Similar baseline price; focus on automation and control |

Machines with more features, like adjustable shot and die strokes, auxiliary hydraulic circuits, and real-time monitoring, cost more. If you need to cast metals with higher melting points, you need specialized materials for the shot sleeve, plunger, and pressure systems. These components must handle high temperatures and pressures, which increases the price.

Advanced control systems regulate the flow of molten metal into the pressure chamber, reducing defects and improving casting quality.

Automatic lubrication and process monitoring systems help extend machine life and lower maintenance costs.

Brand reputation and machine specifications, such as locking force and platen size, also influence the final price.

Note: If you choose a machine with precise control systems and advanced automation, you pay more upfront. However, you get better casting quality, longer service life, and lower operational costs.

Cold chamber die casting uses external melting and a horizontal injection system. You ladle molten metal into the pressure chamber for each cycle. The machine uses a hydraulic plunger to inject the metal at pressures between 2,000 and 20,000 psi. This process requires strong, durable components and precise control.

The pressure chamber must withstand high injection pressures and temperatures.

External melting and ladling systems add complexity and cost.

Machines designed for cold chamber die casting are more expensive than hot chamber machines because they handle metals like aluminum, brass, and copper.

The need for precise control systems increases the price but improves casting quality and reduces defects.

If you need to cast metals with high melting points, you must invest in a machine with specialized materials and advanced pressure regulation. These features help you achieve consistent metal flow and minimize wear on key components.

⚙️ Quick List: What Drives Up Cost?

Higher tonnage and larger pressure chamber

Automation and robotics

Brand reputation and advanced features

Ability to handle high melting point metals

Precise control systems for molten metal injection

When you choose a cold chamber die casting machine, consider your production needs, the size of your parts, and the level of automation you want. The right combination of size, features, and process design will help you balance upfront costs with long-term savings and quality.

When you buy a cold chamber die casting machine, you usually get the main casting unit, a hydraulic system, and a basic control panel. Most cold chamber die casting machines come with a shot sleeve, plunger, and pressure chamber. You also receive standard safety guards and a cooling system. Many manufacturers include a basic set of tools and spare parts for your cold chamber die casting machine. Some suppliers add a simple mold clamping system and a manual ladle for cold chamber casting. You can expect a user manual and basic training for your operators.

Note: The quoted price often covers only the essential cold chamber die casting machine and standard accessories. Always check the list of included items before you buy.

You can upgrade your cold chamber die casting machine with several optional features. Automated ladle transfer systems help you move molten metal into the chamber die casting unit faster. Advanced cooling systems keep your cold chamber die casting machine running at the right temperature. Safety systems, such as light curtains and emergency stops, protect your workers. You might want to add real-time monitoring, servo-driven injection, or robotic part removal. Some cold chamber die casting machines offer energy-saving packages or advanced control software.

Optional Add-On | Benefit |

|---|---|

Automated Ladle Transfer | Faster, safer metal loading |

Advanced Cooling System | Better temperature control |

Safety Systems | Improved operator protection |

Robotic Part Removal | Higher efficiency, less manual labor |

Energy-Saving Features | Lower power costs |

Tip: Optional features can raise the price of your cold chamber die casting machine, but they often improve productivity and safety.

Most suppliers offer installation and setup for your cold chamber die casting machine. You get help with machine alignment, testing, and first runs. Many companies provide operator training and basic maintenance lessons. Some cold chamber die casting machine suppliers include remote support or on-site visits for troubleshooting. You should ask about warranty terms and after-sales service. Good support helps you keep your cold chamber die casting machine running smoothly and reduces downtime.

If you want the best results from your cold chamber die casting machine, choose a supplier with strong installation and support services.

When you choose a cold chamber die casting machine, your production volume plays a big role in cost. For small runs, you face high upfront costs for equipment and tooling. These costs are hard to recover if you only make a few hundred parts. In contrast, large production runs let you spread these costs over thousands of pieces, making each part cheaper.

Here’s a quick comparison:

Production Volume Range | Casting Process Recommendation | Cost Characteristics |

|---|---|---|

Small runs (up to 500/year) | Sand Casting | Low tooling costs, flexible design, but lower surface finish and tolerances |

Medium runs (500-15,000/year) | Permanent Mold Casting | Moderate tooling costs, suitable for medium volumes |

Large runs (10,000+ pieces) | Cold Chamber Die Casting | High initial tooling costs, but cost-effective for large volumes due to high throughput and accuracy |

Tip: Cold chamber die casting machines become more cost-effective as you increase production. The high initial investment pays off with fast cycle times and consistent quality in large runs.

You should compare quotes from several cold chamber die casting machine suppliers to find the best value. Follow these steps to make a smart choice:

Make a shortlist of suppliers using research and referrals.

Request detailed quotes based on your project needs.

Check each supplier’s certifications and customer reviews.

Compare pricing, looking at material selection, part size, and production volume.

Review lead times to match your schedule.

Ask about customization options for your cold chamber die casting machine.

Assess each supplier’s range of materials and machining capabilities.

Evaluate customer support and responsiveness.

Note: Always check for hidden costs like tooling, trimming, and post-processing. These can add up quickly in cold chamber die casting.

You can save money on your cold chamber die casting machine by planning carefully:

Match machine size and clamping force to your actual production needs.

Choose reputable suppliers with good service and spare parts availability.

Balance upfront costs with long-term expenses like energy and maintenance.

Pick machines with energy-saving features to lower operating costs.

Test production dies before final purchase to avoid costly mistakes.

Consider automation to improve efficiency and reduce labor costs.

Watch for extra costs in secondary operations and tooling.

Smart budgeting helps you get the most from your cold chamber die casting machine investment and keeps your production on track.

You will find that cold chamber die casting machine costs range from $10,000 for simple dies to over $200,000 for large, complex dies. Key factors include die complexity, material, production volume, and added features. Here is a quick overview:

Aspect | Cost Range / Details |

|---|---|

Simple Die | $10,000–$20,000 |

Complex Die | $50,000–$100,000+ |

Large Automotive Die | $100,000–$200,000+ |

When you select a cold chamber die casting machine, follow these steps for the best value:

Identify your production needs and metal type.

Compare included features and support.

Request detailed quotes from several suppliers.

Check machine reliability, safety, and efficiency.

Choose equipment that matches your technical standards.

Careful planning helps you make a smart investment and ensures your cold chamber die casting process runs smoothly.

You can use metals with high melting points, such as aluminum, magnesium, and copper alloys. These metals do not work well in hot chamber machines because they can damage the injection system.

The pressure chamber must handle high forces during injection. A strong chamber helps you achieve better part detail and reduces defects. You get more consistent results when the chamber maintains stable pressure.

You must ladle molten metal into the machine because the melting process happens outside the casting unit. This step protects the machine’s internal parts from heat damage and allows you to use metals with higher melting points.

The mold cavity shapes the final part. When you inject molten metal into the cavity, it fills every detail. A well-designed cavity gives you accurate, high-quality castings with smooth surfaces.

You should clean the machine regularly and check for wear on moving parts. Lubricate the system and inspect the hydraulic lines. Routine maintenance helps you avoid breakdowns and keeps your machine running smoothly.