EMAIL:

sales@longhuamachine.com

TELL/whatsapp:

+86-18905522221  English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

You will find that hot chamber die casting uses pressures between 150 and 1200 bar (2,200 to 17,400 psi). Pressure in this process plays a key role in achieving high-quality, fast, and precise results. When you use the right pressure, you ensure complete mold filling, minimize defects, and reach tight tolerances. The table below shows how pressure impacts each aspect of the process:

Aspect | Impact of Pressure in Hot Chamber Die Casting |

|---|---|

Quality | Complete mold filling, fewer defects, correct density |

Speed | Faster injection, shorter cycle times |

Precision | Tight tolerances, accurate detail, risk of defects if pressure is too high |

The Hot Chamber Die Casting Machine relies on controlled pressure to deliver these benefits during every cycle.

Hot chamber die casting uses pressure between 150 and 1200 bar to fill molds quickly and accurately.

Correct pressure ensures complete mold filling, fewer defects, and tight tolerances for strong, detailed parts.

This process works best with low melting point metals like zinc and magnesium that flow easily under pressure.

The machine’s design, including the integrated furnace and gooseneck, helps maintain steady pressure and fast cycles.

Smart part design and matching pressure to the alloy improve casting quality and reduce waste.

You will see that the pressure range for hot chamber die casting usually falls between 150 and 1200 bar. This range equals about 2,200 to 17,400 psi. The pressure die casting process uses this force to inject molten metal into the mold quickly and accurately. Most hot chamber die casting machines operate at pressures around 30 MPa, but some advanced systems can reach up to 175 MPa. The pressure must be high enough to fill the mold cavity before the metal starts to solidify. If you use too little pressure, the casting may have defects or incomplete sections. If you use too much pressure, you risk damaging the mold or causing flash around the edges.

Pressure Range | Typical Value (bar) | Typical Value (psi) |

|---|---|---|

Minimum | 150 | 2,200 |

Maximum | 1200 | 17,400 |

Common Value | 300-700 | 4,350-10,150 |

Tip: Always check the recommended pressure for your specific hot chamber die casting machine and alloy. This helps you avoid defects and ensures consistent casting quality.

You will find that the hot chamber die casting machine uses a special mechanism to generate and control pressure. The casting process starts with an integrated furnace that melts the metal. The molten metal fills the pressure chamber by gravity. A hydraulic plunger, which acts like a syringe, pushes the molten metal through a gooseneck and nozzle into the die cavity. The hydraulic system controls the plunger, allowing you to adjust the pressure for each casting cycle.

The pressure die casting process works like this:

The plunger lifts, letting molten metal fill the chamber.

The plunger then moves down, forcing the metal through the gooseneck into the mold.

The nozzle regulates the flow and prevents air from entering the casting.

The mold stays tightly closed by a double toggle system, which stops leaks during high-pressure injection.

The integrated furnace and injection mechanism allow the casting machine to deliver molten metal directly into the mold. This design enables rapid and continuous casting at the required pressure. You get precise and efficient results, especially for small and intricate parts. The gooseneck structure keeps the molten metal at the right level and helps prevent air entrapment, which improves the quality of each casting.

Note: Advanced hot chamber die casting machines use sensors and control systems to monitor pressure, temperature, and injection speed. These features help you optimize the casting process and produce high-quality parts every time.

You can rely on the hot chamber die casting machine to maintain the correct pressure throughout the casting process. This ensures that each casting meets your standards for strength, detail, and consistency.

You need to use the right pressure in hot chamber die casting because the process works best with metals like zinc and magnesium. These metals have low melting points and flow easily when molten. The pressure range, usually between 1,000 to 5,000 PSI, lets you inject molten metal into the mold quickly. This speed helps you fill the mold before the metal starts to cool and solidify. When you use the correct pressure, you get dense, high-quality casting with fewer defects and less porosity. Zinc and magnesium alloys respond well to this pressure range, so you can produce detailed parts with smooth surfaces and strong structure.

Hot chamber die casting uses alloys that melt at lower temperatures. You can rely on this process to make small and intricate parts, such as connectors, housings, and gears. The pressure ensures the molten metal reaches every part of the mold, so you get accurate casting every time. If you use too little pressure, the mold may not fill completely, and your parts may have weak spots or rough surfaces. Too much pressure can damage the mold or cause unwanted flash on the casting.

Tip: Always match the pressure setting to the alloy you use. This helps you avoid defects and keeps your casting process efficient.

The design of the hot chamber die casting machine affects the pressure you can use and the reliability of your casting process. The machine has an integrated furnace that keeps the metal molten and ready for injection. The gooseneck mechanism plays a key role in maintaining consistent pressure during casting. Here is how it works:

The gooseneck is a bent metal pipe made of heat-resistant steel, submerged in molten metal.

The piston retracts to draw molten metal into the chamber.

The piston then forces the metal through the gooseneck into the mold at high speed and pressure.

The gooseneck transfers molten metal and works with the plunger to inject metal into the die cavity.

This setup ensures a continuous, pressurized flow of molten metal, so you get consistent casting results.

Hot chamber die casting machines operate at lower pressures than cold chamber machines because the injection system is immersed in molten metal. This design lets you fill the mold rapidly and reduces cycle time. You get reliable casting for metals with low melting points, but you cannot use this machine for metals like aluminum that need higher pressures. The integrated design also helps you control the flow of molten metal, so you can optimize mold filling and reduce defects in your parts.

Simulation software helps you adjust casting parameters, such as pressure and temperature, to improve quality. You can use these tools to make sure the molten metal fills the mold evenly and cools at the right rate. This approach reduces scrap and helps you produce strong, detailed parts with every casting cycle.

You need to control pressure carefully during the pressure die casting process to achieve complete mold filling. When you use the right pressure, molten metal flows rapidly and evenly into every part of the mold. This action fills even the smallest gaps and reduces the chance of bubbles or surface irregularities. The table below shows how different pressure levels affect mold filling quality at each stage:

Pressure Range (bar) | Effect on Mold Filling Quality | Process Stage |

|---|---|---|

100–1000 | High pressure forces molten metal rapidly and evenly into the die, filling tiny gaps and reducing bubble formation and surface irregularities | Initial mold filling |

200–400 | Applied after initial filling to remove air gaps, ensuring dense structural integrity and reducing porosity | Injection & solidification |

~500 | Example pressure that can fill the die in 0.02 seconds, demonstrating rapid and complete filling | Mold filling speed |

You also benefit from special design features in the mold. Gating channels control the speed of molten metal, usually between 1–5 m/s, to avoid turbulence and air entrapment. Runner designs help distribute metal evenly, and small vents remove trapped air. These features, combined with pressure die casting, help you produce high-quality die-cast parts with smooth surfaces and strong structure.

Simulation studies show that when you manage pressure well, you reduce turbulence and air entrapment. This leads to better mold filling quality and fewer casting defects.

Pressure die casting plays a key role in preventing defects during the casting process. When you maintain high pressure during both injection and solidification, you make sure the molten metal fills the mold completely. This reduces the risk of incomplete filling and porosity. Pressure also helps push out trapped gases, which can cause gas porosity, and compensates for shrinkage as the metal cools.

You keep the mold tightly closed under pressure, which prevents flash and ensures the casting stays accurate. By holding pressure after filling, you avoid shrinkage porosity and cold shuts. Proper mold design, venting, and temperature control work together with pressure die casting to keep the flow of molten metal smooth and gas-free.

If you want to avoid defects, always monitor and adjust the pressure throughout the casting process. This approach helps you produce strong, reliable castings with consistent quality.

You will notice that both hot chamber die casting and cold chamber die casting machines use high pressure to inject molten metal into the mold. The pressure range for each method is similar, usually between 2,000 and 20,000 psi. The table below shows how these two methods compare:

Die Casting Type | Pressure Range (psi) |

|---|---|

Hot Chamber | 2,000 to 20,000 |

Cold Chamber | 2,000 to 20,000 |

You use a hot chamber die casting machine for metals with low melting points, such as zinc and magnesium. The casting machine keeps molten metal ready for rapid injection, which helps you fill molds quickly and consistently. Cold chamber die casting machines work with metals like aluminum and copper, but the process takes longer because you must transfer molten metal from a separate furnace. Both machines need strong clamping force to keep the mold closed during high-pressure injection, which prevents defects in your castings.

Note: Pressure requirements do not change much for different part sizes, but machine capacity limits the maximum size of castings you can produce.

You will find that the hot chamber die casting machine offers much faster cycle times than cold chamber machines. The built-in furnace and direct injection system let you produce hundreds to thousands of castings per hour. The table below highlights the difference in production speed:

Die Casting Method | Production Speed (Castings per Hour) | Key Process Characteristics |

|---|---|---|

Hot Chamber Die Casting | Hundreds to thousands | Direct molten metal feeding, rapid injection, ideal for small and intricate parts. |

Cold Chamber Die Casting | 15 to 250 | Separate melting and transfer steps, slower cycles, suitable for larger or higher melting point metals. |

You benefit from shorter cycle times with the hot chamber die casting machine, sometimes as fast as 7 seconds per casting. This speed makes it perfect for mass production of small, detailed parts. You also save on tooling costs because the process uses lower operating temperatures, which extends die life and reduces replacement expenses. Hot chamber die casting minimizes waste and oxidation, so you get cleaner castings and lower material costs.

Hot chamber die casting is best for:

Small, intricate parts made from zinc or magnesium.

High-volume applications where speed and cost matter.

Applications of die casting that require smooth surfaces and tight tolerances.

Cold chamber die casting is better for:

Larger castings or parts made from aluminum and copper alloys.

Applications of die casting that need higher melting point metals.

You should choose a hot chamber die casting machine when you want fast, cost-effective production for small parts. The process is not suitable for aluminum, but it excels in applications where you need many castings with precise details. The casting machine helps you achieve high efficiency and lower costs in mass production environments.

You can improve the hot chamber die casting process by focusing on smart part design. The way you design your parts affects how easily molten metal fills the mold and how much pressure you need. Here are some important design tips:

Use uniform wall thickness, usually between 2.5 and 4 mm. This helps molten metal flow smoothly and cool evenly, which lowers the pressure needed to fill the mold.

Add rounded corners and fillets. These features let metal flow better, help gases escape, and reduce stress points. You avoid defects that would otherwise require higher injection pressure.

Minimize undercuts. Fewer undercuts make it easier for metal to move through the mold and for you to remove finished parts. This prevents jamming and keeps pressure requirements lower.

When you follow these design rules, you make the casting process more efficient. Well-designed parts with smooth corners and even walls allow the process to run at lower pressures, which helps you avoid defects and get better results in many applications.

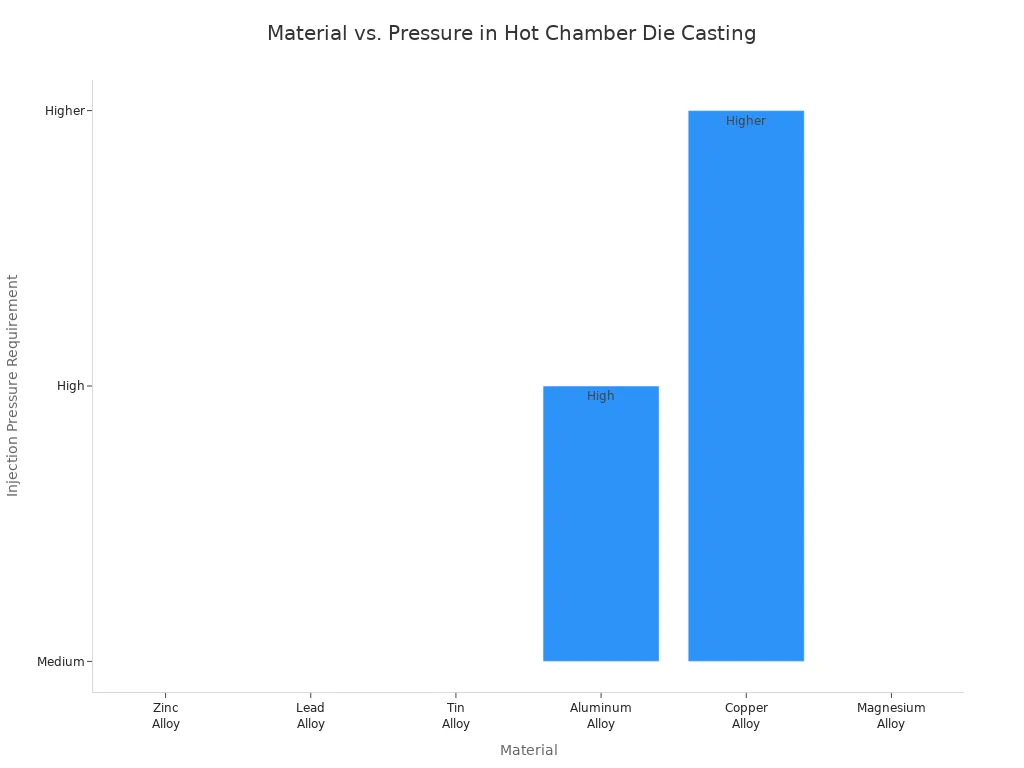

The material you choose for your parts has a big impact on the pressure needed in hot chamber die casting. Alloys with low melting points, like zinc, lead, and tin, work best. These metals flow easily at lower temperatures, so you can use medium injection pressures. Magnesium alloys also work well, needing pressures between 40 and 100 MPa because of their good fluidity and fast solidification. Aluminum and copper alloys need much higher temperatures and pressures, which can damage the equipment and cause oxidation. For most applications, you should pick materials with good fluidity and low melting points to keep the process efficient and the mold safe.

Material | Melting Point (°C) | Suitability for Hot Chamber Die Casting | Injection Pressure Requirement | Notes on Pressure and Equipment |

|---|---|---|---|---|

Zinc Alloy | ~419 | Suitable | Medium | Good fluidity, low pressure needed |

Lead Alloy | ~327 | Suitable | Medium | Very low melting point, easy casting |

Tin Alloy | ~230 | Suitable | Medium | Low melting point, smooth flow |

Aluminum Alloy | ~660 | Not suitable | High | High pressure, equipment strain |

Copper Alloy | ~1000 | Caution | Higher | High pressure, not ideal |

Magnesium Alloy | ~650 | Suitable | Medium | Good fluidity, manageable pressure |

Your machine’s features set the limits for pressure and quality in the casting process. The integrated furnace system keeps molten metal at the right temperature, which helps you produce many parts quickly. High-speed injection mechanisms, like hydraulic pistons, let you inject metal into the mold at high pressure and speed. This ensures the mold fills completely and captures fine details. Automated ejection and die lubrication systems make it easier to remove parts and protect the mold, which improves efficiency and extends mold life. Touchscreen controls let you adjust settings for each application, so you can match the process to your part’s needs. Safety and cooling systems keep the machine running smoothly and prevent overheating, which supports consistent quality.

Machine Capability | Influence on Pressure and Product Quality |

|---|---|

Integrated Furnace System | Keeps metal ready for fast cycles and stable pressure. |

High-Speed Injection Mechanism | Ensures precise mold filling and smooth surfaces. |

Automated Ejection/Lubrication | Reduces cycle time and protects the mold. |

Touchscreen Controls | Lets you fine-tune pressure and monitor the casting process. |

Safety and Cooling Systems | Prevents overheating and keeps quality consistent. |

When you select a hot chamber die casting machine, always check that its maximum pressure, shot volume, and clamping force match your part size and mold requirements. This helps you avoid defects and ensures the casting process runs smoothly for all your applications.

You need to set the right pressure in your Hot Chamber Die Casting Machine to achieve strong, precise castings. Correct pressure selection improves mold filling, reduces defects, and boosts production speed.

Higher pressure enhances tensile strength and lowers porosity, but excessive pressure can damage your hot chamber die casting machine and shorten mold life.

Optimizing pressure helps you save on maintenance costs and increases output, especially when working with hot chamber die casting machine manufacturers.

Regular monitoring and maintenance prevent long-term issues like hydraulic failures and casting defects.

Always balance pressure with temperature, injection speed, and machine capability to maintain quality and efficiency in hot chamber die casting.

A Hot Chamber Die Casting Machine melts metal inside an integrated furnace. You inject molten metal directly into the mold using a hydraulic plunger. This machine works best for metals like zinc and magnesium. You get fast cycles and high-quality parts.

You should use hot chamber die casting for small parts because the process offers fast cycle times and precise detail. The Hot Chamber Die Casting Machine fills molds quickly, making it ideal for high-volume production of intricate components.

You set the right pressure by following the machine’s guidelines and matching it to your alloy. Most hot chamber die casting machines let you adjust pressure using touchscreen controls. Always check the recommended settings from hot chamber die casting machine manufacturers.

You get the best results with zinc, magnesium, lead, and tin alloys. These metals have low melting points and flow easily. Hot chamber die casting machines cannot handle aluminum or copper because they require higher temperatures and pressures.

Hot chamber die casting machine manufacturers add features like automated controls, advanced sensors, and efficient cooling systems. These upgrades help you maintain stable pressure, reduce defects, and produce consistent, high-quality castings every cycle.