EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-HDC-68T

LONGHUA

Utilizing the hot chamber technology, it allows for the direct feeding of molten metal into the casting chamber, facilitating rapid and efficient production cycles. This machine is particularly effective for casting metals like zinc and aluminum alloys and is widely used in industries requiring high - precision metal components. Its compact size and high - efficiency operation make it suitable for both small - batch production and mass manufacturing.

Stable Clamping Force

Provides a reliable clamping force of 68 tons to ensure precise mold closure during casting. This stability results in castings with excellent dimensional accuracy and surface finish.

Integrated Melting Unit

Built - in melting unit keeps metal in a molten state, enabling continuous and efficient operation. The melting unit is designed for quick and efficient metal turnover.

Precision Metering

Accurately measures and controls the volume of molten metal injected into the mold for consistent product quality. The metering system ensures precise control over the casting weight and size.

Quick Cycle Times

Designed for fast operation cycles to maximize production output. The machine's hydraulic system is optimized for rapid injection and mold opening/closing sequences.

Safety Protections

Includes various safety features such as emergency stop buttons, protective shielding, and safety interlocks to protect operators and ensure safe machine operation.

Easy - to - Use Controls

Equipped with a straightforward control system featuring digital displays and programmable settings for easy setup and operation. The control panel allows for quick adjustment of casting parameters.

Compact Design

The machine's footprint is minimized without sacrificing functionality, making it suitable for workshops with limited space.

Low Maintenance

Features components that are easily accessible for maintenance and equipped with wear - resistant materials to reduce downtime and maintenance frequency.

Consumer Electronics

Produces precision parts for devices such as smartphones and tablets. The machine's ability to produce small, intricate castings makes it ideal for electronic components.

Lighting Industry

Used to manufacture metal components for lighting fixtures and LED products. It produces heat - sinks and housing components with excellent thermal conductivity and mechanical strength.

Telecommunications

Creates metal parts for communication equipment and infrastructure, such as connectors and enclosures.

Small - Scale Industrial Components

Suited for producing a variety of small - sized industrial metal parts, including gears, fasteners, and decorative components.

Medical Devices

Produces precision - engineered parts for medical equipment where high - tolerance casting and material purity are critical.

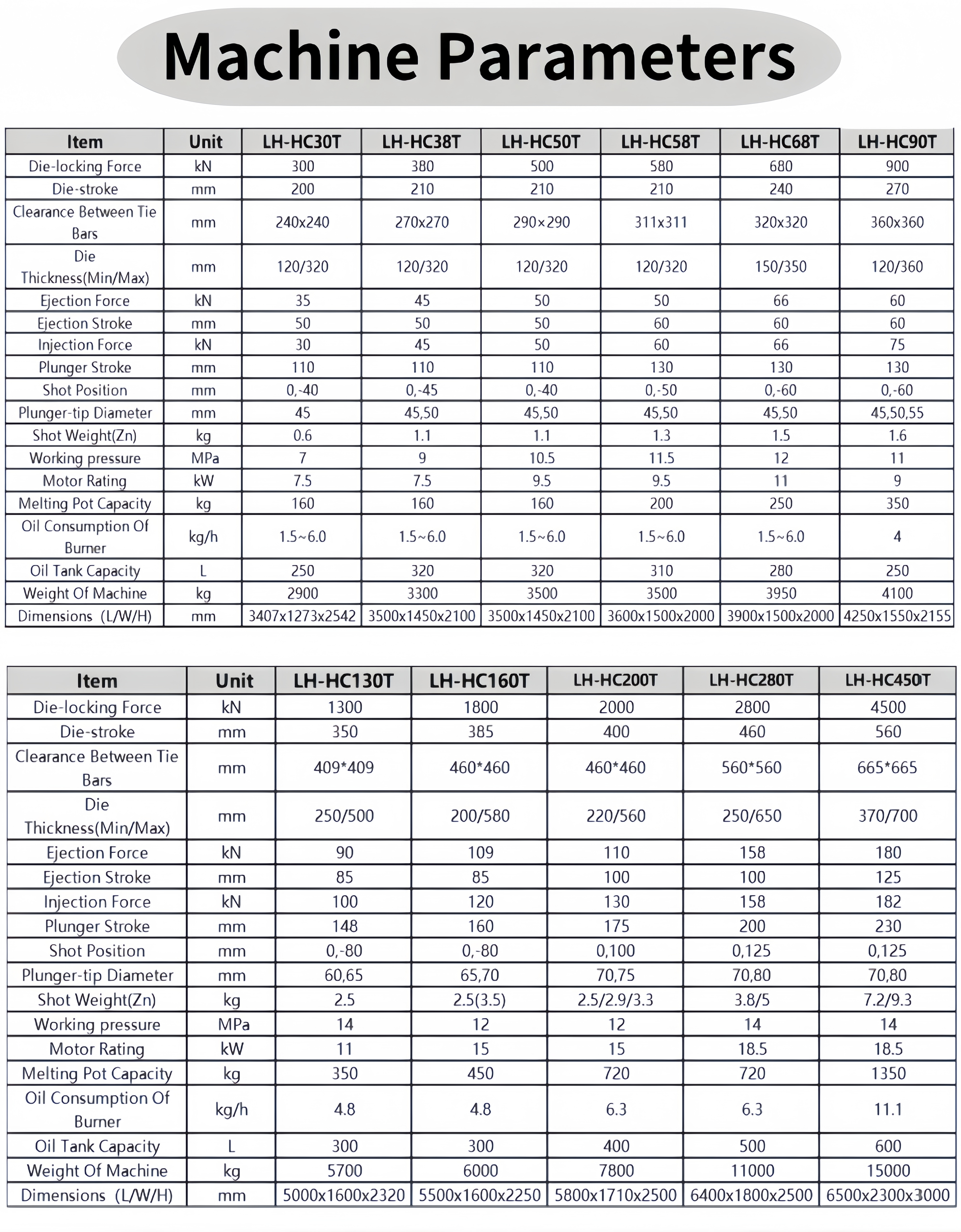

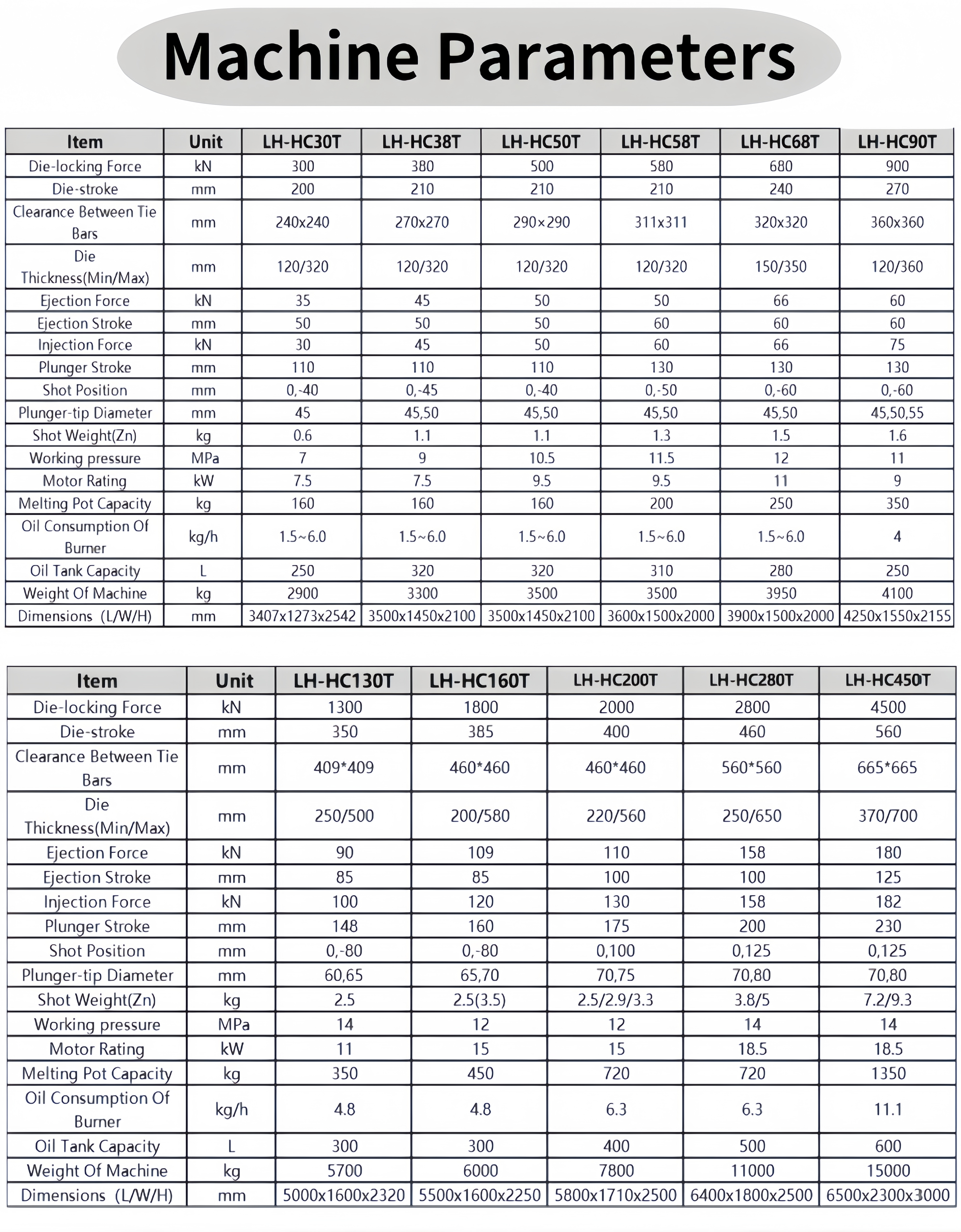

(Due to the continuous progress of science and technology, the picture,parameter configuration, etc. will not be changed without notice)

Utilizing the hot chamber technology, it allows for the direct feeding of molten metal into the casting chamber, facilitating rapid and efficient production cycles. This machine is particularly effective for casting metals like zinc and aluminum alloys and is widely used in industries requiring high - precision metal components. Its compact size and high - efficiency operation make it suitable for both small - batch production and mass manufacturing.

Stable Clamping Force

Provides a reliable clamping force of 68 tons to ensure precise mold closure during casting. This stability results in castings with excellent dimensional accuracy and surface finish.

Integrated Melting Unit

Built - in melting unit keeps metal in a molten state, enabling continuous and efficient operation. The melting unit is designed for quick and efficient metal turnover.

Precision Metering

Accurately measures and controls the volume of molten metal injected into the mold for consistent product quality. The metering system ensures precise control over the casting weight and size.

Quick Cycle Times

Designed for fast operation cycles to maximize production output. The machine's hydraulic system is optimized for rapid injection and mold opening/closing sequences.

Safety Protections

Includes various safety features such as emergency stop buttons, protective shielding, and safety interlocks to protect operators and ensure safe machine operation.

Easy - to - Use Controls

Equipped with a straightforward control system featuring digital displays and programmable settings for easy setup and operation. The control panel allows for quick adjustment of casting parameters.

Compact Design

The machine's footprint is minimized without sacrificing functionality, making it suitable for workshops with limited space.

Low Maintenance

Features components that are easily accessible for maintenance and equipped with wear - resistant materials to reduce downtime and maintenance frequency.

Consumer Electronics

Produces precision parts for devices such as smartphones and tablets. The machine's ability to produce small, intricate castings makes it ideal for electronic components.

Lighting Industry

Used to manufacture metal components for lighting fixtures and LED products. It produces heat - sinks and housing components with excellent thermal conductivity and mechanical strength.

Telecommunications

Creates metal parts for communication equipment and infrastructure, such as connectors and enclosures.

Small - Scale Industrial Components

Suited for producing a variety of small - sized industrial metal parts, including gears, fasteners, and decorative components.

Medical Devices

Produces precision - engineered parts for medical equipment where high - tolerance casting and material purity are critical.

(Due to the continuous progress of science and technology, the picture,parameter configuration, etc. will not be changed without notice)