EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-mould-auto parts

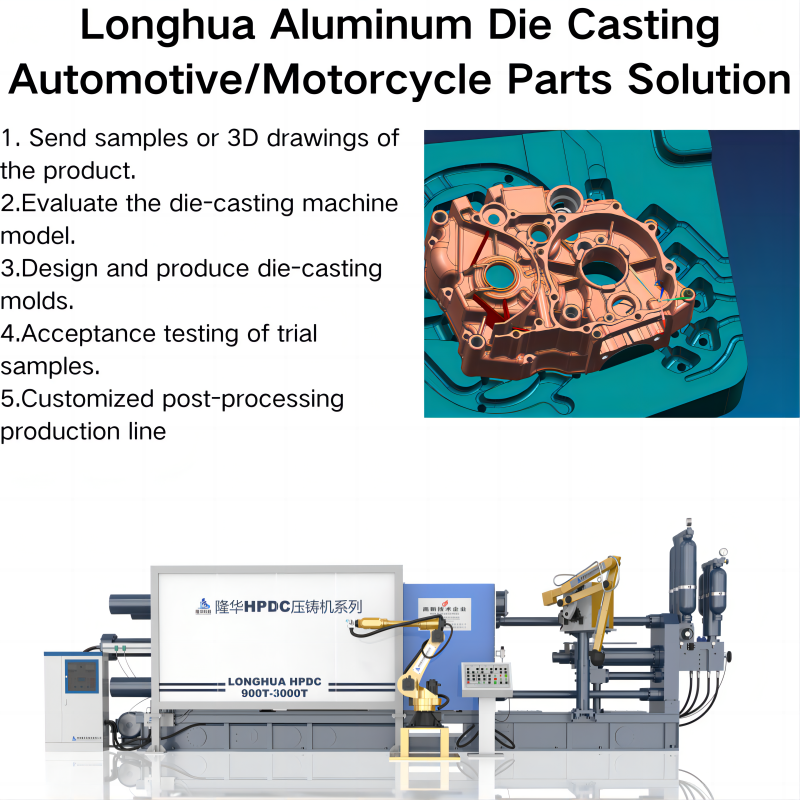

Custom-designed aluminum die casting molds exclusively for automotive parts (engine brackets, transmission housings, piston components, etc.).

Optimized for aluminum alloys (ADC12, A380, A356) — the most common materials in automotive lightweighting.

Achieves ±0.02mm positioning accuracy and 500,000+ cycle lifespan to ensure consistent mass production.

Supports 1-8 cavity configurations to match low-volume prototypes (1,000 pieces) and high-volume production (1M+ pieces).

Integrates heat-resistant structures to withstand 650-750℃ molten aluminum thermal cycles without deformation.

Complies with automotive industry standards (IATF 16949, ISO 9001) for material safety and part precision.

Visually, the mold has a robust, matte-gray H13 steel frame with clean, uniform surfaces — no rough edges or air bubbles (common in cheap molds) that trap molten aluminum. When you touch the cavity surface, it feels ultra-smooth (Ra 0.4μm) and cool to the touch (even after 100 casting cycles) thanks to the integrated cooling channels. The mold’s guide pins are polished to a mirror finish, sliding into bushings with a nearly silent “slick” sound (no grinding) that signals precise alignment. There’s a faint, metallic scent (no chemical odors from low-quality coatings), a sign of premium heat-treated steel. During casting, you’ll notice molten aluminum flows evenly into every cavity (no dead zones) with a steady, soft “gurgle” — unlike generic molds that cause splashing or incomplete filling. After cooling, the mold opens smoothly, and parts pop out cleanly (no sticking) — you can run your finger over a freshly cast transmission housing and feel no burrs, eliminating 2 hours of post-trimming per batch. Every detail — from the etched part number (scratch-resistant, easy to track) to the reinforced mold base (supports 500kg clamping force) — is designed to make automotive aluminum casting efficient and reliable for B2B manufacturers.

Long-Lasting Thermal Durability: Made from H13 hot-work die steel (tensile strength 1,800MPa) with triple tempering (52-54 HRC hardness) — withstands 650-750℃ molten aluminum thermal cycles without warping. This extends mold lifespan to 500,000+ cycles (vs. 150,000 cycles for generic P20 steel molds). A Chinese automotive parts factory using 8 molds reported saving $48,000/year in replacement costs (3 fewer mold changes annually) and 120 hours of downtime. The mold’s integrated cooling channels (0.8mm wall thickness) also reduce cycle time by 15% (from 60s to 51s) by accelerating part solidification.

Automotive-Grade Precision: Achieves ±0.02mm positioning accuracy via CNC grinding (tolerance ±0.005mm) and EDM wire cutting (surface roughness Ra 0.2μm). This ensures cast parts meet automotive assembly standards (e.g., ISO 8062 for dimensional tolerances) — a German factory producing engine brackets reduced rejection rates from 12% to 3%, saving 2,700kg of aluminum scrap yearly (worth $5,400). The mold’s cavity surface is treated with a nanoscale ceramic coating (10μm thick) that reduces aluminum adhesion by 85%, eliminating “sticking parts” that cause 70% of manual intervention in casting lines.

Flexible Cavity Configuration: Supports 1-8 cavity designs to match production volume needs — 1-cavity for high-precision prototypes (e.g., custom EV battery housings), 8-cavity for high-volume parts (e.g., small sensor brackets). Our modular cavity inserts allow switching between 2-4 cavities in 4 hours (vs. 8 hours for one-piece molds), ideal for factories with mixed-order production. A U.S. EV parts supplier used a 4-cavity mold for mass production (100,000 pieces/month) and quickly reconfigured it to 2-cavity for a prototype order, avoiding $15,000 in extra mold costs.

Rapid Customization & Delivery: SOur in-house 3D printing lab creates prototype cavities in 3 days, letting customers verify part design before full mold production — a Korean automotive factory reduced design iterations from 3 to 1, cutting 2 weeks from the project timeline. For urgent orders (e.g., 2-week rush for a recall part), we offer expedited production (18 days) with no extra cost, helping customers avoid $100,000+ in late-delivery penalties.

Full Compliance with Automotive Standards: Manufactured under IATF 16949 (automotive quality management) and ISO 9001 certifications, with materials traceable to mill test reports (MTRs). The mold’s steel meets RoHS and REACH requirements for heavy metal limits, ensuring cast parts pass global automotive regulatory checks (e.g., EU ELV Directive). A Mexican automotive supplier used our molds to gain certification from Ford and GM, expanding their export market by 40%.4. Technical Parameters (Table)

| Parameter Name | Specification |

| Applicable Aluminum Alloys | ADC12, A380, A356, A6061 |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Cavity Quantity | 1-8 Cavities (Modular Inserts) |

| Positioning Accuracy | ±0.02mm |

| Surface Roughness (Cavity) | Ra 0.2-0.4μm (After Polishing) |

| Mold Lifespan | 500,000+ Cycles (ADC12 Aluminum) |

| Maximum Clamping Force | 2,000kN (Compatible with 300T-1200T Die Casting Machines) |

| Thermal Cycle Resistance | 650-750℃ (Continuous Operation) |

| Cooling System | Integrated Water Channels (0.8mm Wall Thickness) |

| Surface Coating | Nanoscale Ceramic Coating (10μm Thick, Anti-Adhesion) |

| Customization Lead Time | 25-45 Days (Standard); 18 Days (Expedited) |

| Dimensions (L×W×H) | 500×300×200mm (1-Cavity) to 1200×800×400mm (8-Cavity) |

| Net Weight | 80kg (1-Cavity) to 550kg (8-Cavity) |

| Certifications | IATF 16949, ISO 9001, RoHS, REACH |

| Compatibility | 300T-1200T Cold-Chamber Die Casting Machines (LH, Yizumi, Haitian) |

| Quality Testing | 3D Coordinate Measuring (CMM), Hardness Testing (Rockwell), Thermal Cycle Testing |

| Warranty | 1 Year (Structural Defects); 6 Months (Coating Wear) |

Engine Components (Engine Brackets, Piston Housings): Ideal for ADC12 aluminum engine brackets requiring ±0.03mm hole alignment (for bolt assembly). The mold’s H13 steel and cooling channels ensure 500,000+ cycles of consistent casting — a Chinese factory producing 500,000 brackets/year reduced mold replacement from 4 to 1 times/year, saving $36,000.

Transmission & Drivetrain Parts (Gear Housings, Shaft Supports): Perfect for A380 aluminum transmission housings with complex internal ribs (2mm thick). The mold’s EDM-cut cavities capture fine details without underfilling, and the anti-adhesion coating prevents rib damage during demolding. A German factory increased transmission housing pass rate from 88% to 99%, avoiding $20,000 in rework monthly.

EV-Specific Parts (Battery Housings, Motor Casings): Suitable for A6061 aluminum EV battery housings (large, thin-walled: 1.5mm thickness). The 1-2 cavity modular design supports prototype-to-mass production (1,000→100,000 pieces), and the mold’s thermal stability ensures uniform wall thickness (variation ≤0.1mm) — critical for battery safety. A U.S. EV startup used our mold to launch their battery housing in 45 days, 30 days faster than competitors.

Small Precision Parts (Sensor Brackets, Connector Housings): The 6-8 cavity configuration meets high-volume demand (1M+ pieces/year) for small A356 aluminum sensor brackets. The mold’s ±0.02mm accuracy ensures bracket holes align with sensors, reducing assembly time by 20%. A Korean automotive electronics supplier cut labor costs by $12,000/year with this efficiency gain.

Custom Aftermarket Parts (Performance Engine Components): Supports low-volume (1,000-10,000 pieces) custom molds for aftermarket parts (e.g., performance intake manifolds). Our rapid 25-day lead time lets aftermarket brands quickly respond to market trends — a U.S. aftermarket supplier launched 3 new manifold designs in 6 months, increasing revenue by 25%.

Needs Assessment & Design Consultation (3-5 Days):

Our automotive mold engineers review your part 3D model (STEP/IGES files) and production requirements (volume, alloy type, die casting machine model).

We provide design recommendations (e.g., adding draft angles for easy demolding, optimizing rib thickness to prevent cracking) based on 10+ years of automotive casting experience.

Example: For a customer’s EV motor casing, we suggested adjusting cavity cooling channels to reduce cycle time by 18% — a change that saved them $8,000/year.

3D Mold Design & Prototype Verification (7-10 Days):

Create detailed 3D mold models (including cavities, cooling channels, guide pins) using SolidWorks and AutoCAD.

3D-print a prototype cavity (resin or metal) to test with your aluminum alloy — you receive 5-10 sample parts to validate fit, finish, and dimensional accuracy.

We revise the design based on your feedback (e.g., adjusting cavity size for shrinkage) — 95% of customers approve the design after 1-2 iterations.

Mold Material Selection & Preprocessing (5-7 Days):

Source H13 die steel from certified mills (with MTRs) and cut to mold blank size using CNC sawing.

Perform initial heat treatment (annealing) to reduce steel stress — critical for preventing mold warping during casting.

Provide material certification to your quality team for compliance (e.g., IATF 16949 documentation).

Precision Manufacturing & Coating (7-15 Days):

Use CNC milling (tolerance ±0.005mm) and EDM wire cutting to shape cavities and cooling channels.

Polish cavity surfaces to Ra 0.2μm and apply nanoscale ceramic anti-adhesion coating.

Assemble mold components (cavities, guide pins, cooling fittings) and test mechanical movement (e.g., mold opening/closing) to ensure smooth operation.

Test Run & Delivery (3-5 Days):

Conduct a test run on our in-house 500T die casting machine (using your aluminum alloy) to produce 100-200 sample parts.

Inspect samples via CMM for dimensional accuracy and share test reports with you.

Deliver the mold with a complete kit (spare cavity inserts, maintenance tools, operation manual) and provide on-site installation guidance (free for orders over 1 mold).

Material Inspection: Verify H13 steel hardness (52-54 HRC) via Rockwell testing and check for internal defects (e.g., cracks) using ultrasonic testing (UT).

Dimensional Accuracy: Use a Zeiss CMM (accuracy ±0.001mm) to measure cavity size, positioning, and cooling channel diameter — all data is logged in a traceable report.

Surface Finish: Test cavity roughness with a profilometer (Ra 0.2-0.4μm) and visually inspect for scratches or burrs (magnification 10x).

Thermal Cycle Testing: Subject the mold to 1,000 simulated casting cycles (650℃ heating → 200℃ cooling) to check for warping or coating wear.

Mechanical Function Test: Test mold opening/closing (1,000 cycles) to ensure guide pin alignment and smooth movement — no stuck components or abnormal noise.

Compliance Documentation: Generate IATF 16949 process records, MTRs for steel, and RoHS/REACH compliance certificates for delivery.

Sample Part Validation: Cast 100 sample parts and inspect them against your part drawing — only molds with ≥99% sample pass rate are approved for delivery.

Warranty Coverage: 1-year warranty for structural defects (e.g., cracked mold base) and 6-month warranty for anti-adhesion coating wear. If a defect occurs, we repair/replace the mold for free and cover shipping costs (global).

24/7 Technical Support: Our team of 6 automotive mold engineers (10+ years experience) offers round-the-clock support via phone, WhatsApp, and video call. For urgent issues (e.g., mold cavity damage during production), we respond within 30 minutes and provide temporary solutions (e.g., expedited spare inserts).

Spare Parts Supply: Stock core spare parts (cavity inserts, guide pins, coating kits) in 3 regional warehouses (China, Germany, U.S.). For urgent needs, we offer 24-hour delivery — a Brazilian factory received replacement cavity inserts in 16 hours, minimizing downtime to 4 hours.

Maintenance Training: Provide free on-site training (1 day) for your maintenance team — covering mold disassembly, cleaning, coating reapplication, and cooling system flushing. A Thai factory’s team reduced mold maintenance time by 40% after training, extending mold lifespan by 10%.

Mold Refurbishment: After warranty expiration, we offer cost-effective refurbishment (resurfacing cavities, re-coating, heat treatment) for 40% of the cost of a new mold. A Chinese factory refurbished 5 molds after 500,000 cycles, saving $120,000 in new mold costs.

Specialization in Automotive Aluminum Die Casting Molds: We don’t make generic molds — we focus exclusively on automotive applications, with 10+ years of experience designing molds for engine, transmission, and EV parts. Our engineers understand automotive-specific challenges (e.g., lightweighting, thermal stability) and translate them into mold features that solve actual production pain points.

Proven OEM Collaboration Track Record: Over 200 automotive parts manufacturers in 35 countries use our molds, including suppliers to Ford, GM, VW, and BYD. A Chinese OEM supplier increased their annual revenue by $2M after using our molds to meet Toyota’s strict precision requirements — they’ve renewed their annual order for 5 consecutive years.

Transparent Cost & ROI: We provide a detailed ROI calculator (based on your production volume, scrap rate, and mold replacement costs) to show exactly when you’ll recoup your investment. Most customers see ROI in 6-8 months (e.g., a factory with 10,000 parts/day saves $5,000/month in scrap and downtime).

Rapid Lead Times & Flexibility: Our 25-45 day customization cycle is 30% faster than competitors, and we offer expedited delivery for urgent orders. For customers with changing needs (e.g., design revisions mid-project), we adjust the mold design at no extra cost — a U.S. EV factory changed their battery housing design 2 weeks into production, and we revised the mold without delaying delivery.

Full Compliance & Traceability: Every mold comes with complete documentation (MTRs, test reports, compliance certificates) to meet automotive OEM audit requirements. We retain process records for 5 years, ensuring full traceability if you need to validate mold history for regulatory checks.

Q1: Can you design a mold for our custom EV battery housing (size: 1200×600×150mm, A6061 aluminum)?

Q2: How do you ensure the mold’s precision matches our part’s ±0.03mm tolerance for engine brackets?

Q3: What if our die casting machine is a 300T Yizumi (older model) — will the mold be compatible?

Q4: How long will the anti-adhesion coating last, and can we reapply it ourselves?

Custom-designed aluminum die casting molds exclusively for automotive parts (engine brackets, transmission housings, piston components, etc.).

Optimized for aluminum alloys (ADC12, A380, A356) — the most common materials in automotive lightweighting.

Achieves ±0.02mm positioning accuracy and 500,000+ cycle lifespan to ensure consistent mass production.

Supports 1-8 cavity configurations to match low-volume prototypes (1,000 pieces) and high-volume production (1M+ pieces).

Integrates heat-resistant structures to withstand 650-750℃ molten aluminum thermal cycles without deformation.

Complies with automotive industry standards (IATF 16949, ISO 9001) for material safety and part precision.

Visually, the mold has a robust, matte-gray H13 steel frame with clean, uniform surfaces — no rough edges or air bubbles (common in cheap molds) that trap molten aluminum. When you touch the cavity surface, it feels ultra-smooth (Ra 0.4μm) and cool to the touch (even after 100 casting cycles) thanks to the integrated cooling channels. The mold’s guide pins are polished to a mirror finish, sliding into bushings with a nearly silent “slick” sound (no grinding) that signals precise alignment. There’s a faint, metallic scent (no chemical odors from low-quality coatings), a sign of premium heat-treated steel. During casting, you’ll notice molten aluminum flows evenly into every cavity (no dead zones) with a steady, soft “gurgle” — unlike generic molds that cause splashing or incomplete filling. After cooling, the mold opens smoothly, and parts pop out cleanly (no sticking) — you can run your finger over a freshly cast transmission housing and feel no burrs, eliminating 2 hours of post-trimming per batch. Every detail — from the etched part number (scratch-resistant, easy to track) to the reinforced mold base (supports 500kg clamping force) — is designed to make automotive aluminum casting efficient and reliable for B2B manufacturers.

Long-Lasting Thermal Durability: Made from H13 hot-work die steel (tensile strength 1,800MPa) with triple tempering (52-54 HRC hardness) — withstands 650-750℃ molten aluminum thermal cycles without warping. This extends mold lifespan to 500,000+ cycles (vs. 150,000 cycles for generic P20 steel molds). A Chinese automotive parts factory using 8 molds reported saving $48,000/year in replacement costs (3 fewer mold changes annually) and 120 hours of downtime. The mold’s integrated cooling channels (0.8mm wall thickness) also reduce cycle time by 15% (from 60s to 51s) by accelerating part solidification.

Automotive-Grade Precision: Achieves ±0.02mm positioning accuracy via CNC grinding (tolerance ±0.005mm) and EDM wire cutting (surface roughness Ra 0.2μm). This ensures cast parts meet automotive assembly standards (e.g., ISO 8062 for dimensional tolerances) — a German factory producing engine brackets reduced rejection rates from 12% to 3%, saving 2,700kg of aluminum scrap yearly (worth $5,400). The mold’s cavity surface is treated with a nanoscale ceramic coating (10μm thick) that reduces aluminum adhesion by 85%, eliminating “sticking parts” that cause 70% of manual intervention in casting lines.

Flexible Cavity Configuration: Supports 1-8 cavity designs to match production volume needs — 1-cavity for high-precision prototypes (e.g., custom EV battery housings), 8-cavity for high-volume parts (e.g., small sensor brackets). Our modular cavity inserts allow switching between 2-4 cavities in 4 hours (vs. 8 hours for one-piece molds), ideal for factories with mixed-order production. A U.S. EV parts supplier used a 4-cavity mold for mass production (100,000 pieces/month) and quickly reconfigured it to 2-cavity for a prototype order, avoiding $15,000 in extra mold costs.

Rapid Customization & Delivery: SOur in-house 3D printing lab creates prototype cavities in 3 days, letting customers verify part design before full mold production — a Korean automotive factory reduced design iterations from 3 to 1, cutting 2 weeks from the project timeline. For urgent orders (e.g., 2-week rush for a recall part), we offer expedited production (18 days) with no extra cost, helping customers avoid $100,000+ in late-delivery penalties.

Full Compliance with Automotive Standards: Manufactured under IATF 16949 (automotive quality management) and ISO 9001 certifications, with materials traceable to mill test reports (MTRs). The mold’s steel meets RoHS and REACH requirements for heavy metal limits, ensuring cast parts pass global automotive regulatory checks (e.g., EU ELV Directive). A Mexican automotive supplier used our molds to gain certification from Ford and GM, expanding their export market by 40%.4. Technical Parameters (Table)

| Parameter Name | Specification |

| Applicable Aluminum Alloys | ADC12, A380, A356, A6061 |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Cavity Quantity | 1-8 Cavities (Modular Inserts) |

| Positioning Accuracy | ±0.02mm |

| Surface Roughness (Cavity) | Ra 0.2-0.4μm (After Polishing) |

| Mold Lifespan | 500,000+ Cycles (ADC12 Aluminum) |

| Maximum Clamping Force | 2,000kN (Compatible with 300T-1200T Die Casting Machines) |

| Thermal Cycle Resistance | 650-750℃ (Continuous Operation) |

| Cooling System | Integrated Water Channels (0.8mm Wall Thickness) |

| Surface Coating | Nanoscale Ceramic Coating (10μm Thick, Anti-Adhesion) |

| Customization Lead Time | 25-45 Days (Standard); 18 Days (Expedited) |

| Dimensions (L×W×H) | 500×300×200mm (1-Cavity) to 1200×800×400mm (8-Cavity) |

| Net Weight | 80kg (1-Cavity) to 550kg (8-Cavity) |

| Certifications | IATF 16949, ISO 9001, RoHS, REACH |

| Compatibility | 300T-1200T Cold-Chamber Die Casting Machines (LH, Yizumi, Haitian) |

| Quality Testing | 3D Coordinate Measuring (CMM), Hardness Testing (Rockwell), Thermal Cycle Testing |

| Warranty | 1 Year (Structural Defects); 6 Months (Coating Wear) |

Engine Components (Engine Brackets, Piston Housings): Ideal for ADC12 aluminum engine brackets requiring ±0.03mm hole alignment (for bolt assembly). The mold’s H13 steel and cooling channels ensure 500,000+ cycles of consistent casting — a Chinese factory producing 500,000 brackets/year reduced mold replacement from 4 to 1 times/year, saving $36,000.

Transmission & Drivetrain Parts (Gear Housings, Shaft Supports): Perfect for A380 aluminum transmission housings with complex internal ribs (2mm thick). The mold’s EDM-cut cavities capture fine details without underfilling, and the anti-adhesion coating prevents rib damage during demolding. A German factory increased transmission housing pass rate from 88% to 99%, avoiding $20,000 in rework monthly.

EV-Specific Parts (Battery Housings, Motor Casings): Suitable for A6061 aluminum EV battery housings (large, thin-walled: 1.5mm thickness). The 1-2 cavity modular design supports prototype-to-mass production (1,000→100,000 pieces), and the mold’s thermal stability ensures uniform wall thickness (variation ≤0.1mm) — critical for battery safety. A U.S. EV startup used our mold to launch their battery housing in 45 days, 30 days faster than competitors.

Small Precision Parts (Sensor Brackets, Connector Housings): The 6-8 cavity configuration meets high-volume demand (1M+ pieces/year) for small A356 aluminum sensor brackets. The mold’s ±0.02mm accuracy ensures bracket holes align with sensors, reducing assembly time by 20%. A Korean automotive electronics supplier cut labor costs by $12,000/year with this efficiency gain.

Custom Aftermarket Parts (Performance Engine Components): Supports low-volume (1,000-10,000 pieces) custom molds for aftermarket parts (e.g., performance intake manifolds). Our rapid 25-day lead time lets aftermarket brands quickly respond to market trends — a U.S. aftermarket supplier launched 3 new manifold designs in 6 months, increasing revenue by 25%.

Needs Assessment & Design Consultation (3-5 Days):

Our automotive mold engineers review your part 3D model (STEP/IGES files) and production requirements (volume, alloy type, die casting machine model).

We provide design recommendations (e.g., adding draft angles for easy demolding, optimizing rib thickness to prevent cracking) based on 10+ years of automotive casting experience.

Example: For a customer’s EV motor casing, we suggested adjusting cavity cooling channels to reduce cycle time by 18% — a change that saved them $8,000/year.

3D Mold Design & Prototype Verification (7-10 Days):

Create detailed 3D mold models (including cavities, cooling channels, guide pins) using SolidWorks and AutoCAD.

3D-print a prototype cavity (resin or metal) to test with your aluminum alloy — you receive 5-10 sample parts to validate fit, finish, and dimensional accuracy.

We revise the design based on your feedback (e.g., adjusting cavity size for shrinkage) — 95% of customers approve the design after 1-2 iterations.

Mold Material Selection & Preprocessing (5-7 Days):

Source H13 die steel from certified mills (with MTRs) and cut to mold blank size using CNC sawing.

Perform initial heat treatment (annealing) to reduce steel stress — critical for preventing mold warping during casting.

Provide material certification to your quality team for compliance (e.g., IATF 16949 documentation).

Precision Manufacturing & Coating (7-15 Days):

Use CNC milling (tolerance ±0.005mm) and EDM wire cutting to shape cavities and cooling channels.

Polish cavity surfaces to Ra 0.2μm and apply nanoscale ceramic anti-adhesion coating.

Assemble mold components (cavities, guide pins, cooling fittings) and test mechanical movement (e.g., mold opening/closing) to ensure smooth operation.

Test Run & Delivery (3-5 Days):

Conduct a test run on our in-house 500T die casting machine (using your aluminum alloy) to produce 100-200 sample parts.

Inspect samples via CMM for dimensional accuracy and share test reports with you.

Deliver the mold with a complete kit (spare cavity inserts, maintenance tools, operation manual) and provide on-site installation guidance (free for orders over 1 mold).

Material Inspection: Verify H13 steel hardness (52-54 HRC) via Rockwell testing and check for internal defects (e.g., cracks) using ultrasonic testing (UT).

Dimensional Accuracy: Use a Zeiss CMM (accuracy ±0.001mm) to measure cavity size, positioning, and cooling channel diameter — all data is logged in a traceable report.

Surface Finish: Test cavity roughness with a profilometer (Ra 0.2-0.4μm) and visually inspect for scratches or burrs (magnification 10x).

Thermal Cycle Testing: Subject the mold to 1,000 simulated casting cycles (650℃ heating → 200℃ cooling) to check for warping or coating wear.

Mechanical Function Test: Test mold opening/closing (1,000 cycles) to ensure guide pin alignment and smooth movement — no stuck components or abnormal noise.

Compliance Documentation: Generate IATF 16949 process records, MTRs for steel, and RoHS/REACH compliance certificates for delivery.

Sample Part Validation: Cast 100 sample parts and inspect them against your part drawing — only molds with ≥99% sample pass rate are approved for delivery.

Warranty Coverage: 1-year warranty for structural defects (e.g., cracked mold base) and 6-month warranty for anti-adhesion coating wear. If a defect occurs, we repair/replace the mold for free and cover shipping costs (global).

24/7 Technical Support: Our team of 6 automotive mold engineers (10+ years experience) offers round-the-clock support via phone, WhatsApp, and video call. For urgent issues (e.g., mold cavity damage during production), we respond within 30 minutes and provide temporary solutions (e.g., expedited spare inserts).

Spare Parts Supply: Stock core spare parts (cavity inserts, guide pins, coating kits) in 3 regional warehouses (China, Germany, U.S.). For urgent needs, we offer 24-hour delivery — a Brazilian factory received replacement cavity inserts in 16 hours, minimizing downtime to 4 hours.

Maintenance Training: Provide free on-site training (1 day) for your maintenance team — covering mold disassembly, cleaning, coating reapplication, and cooling system flushing. A Thai factory’s team reduced mold maintenance time by 40% after training, extending mold lifespan by 10%.

Mold Refurbishment: After warranty expiration, we offer cost-effective refurbishment (resurfacing cavities, re-coating, heat treatment) for 40% of the cost of a new mold. A Chinese factory refurbished 5 molds after 500,000 cycles, saving $120,000 in new mold costs.

Specialization in Automotive Aluminum Die Casting Molds: We don’t make generic molds — we focus exclusively on automotive applications, with 10+ years of experience designing molds for engine, transmission, and EV parts. Our engineers understand automotive-specific challenges (e.g., lightweighting, thermal stability) and translate them into mold features that solve actual production pain points.

Proven OEM Collaboration Track Record: Over 200 automotive parts manufacturers in 35 countries use our molds, including suppliers to Ford, GM, VW, and BYD. A Chinese OEM supplier increased their annual revenue by $2M after using our molds to meet Toyota’s strict precision requirements — they’ve renewed their annual order for 5 consecutive years.

Transparent Cost & ROI: We provide a detailed ROI calculator (based on your production volume, scrap rate, and mold replacement costs) to show exactly when you’ll recoup your investment. Most customers see ROI in 6-8 months (e.g., a factory with 10,000 parts/day saves $5,000/month in scrap and downtime).

Rapid Lead Times & Flexibility: Our 25-45 day customization cycle is 30% faster than competitors, and we offer expedited delivery for urgent orders. For customers with changing needs (e.g., design revisions mid-project), we adjust the mold design at no extra cost — a U.S. EV factory changed their battery housing design 2 weeks into production, and we revised the mold without delaying delivery.

Full Compliance & Traceability: Every mold comes with complete documentation (MTRs, test reports, compliance certificates) to meet automotive OEM audit requirements. We retain process records for 5 years, ensuring full traceability if you need to validate mold history for regulatory checks.

Q1: Can you design a mold for our custom EV battery housing (size: 1200×600×150mm, A6061 aluminum)?

Q2: How do you ensure the mold’s precision matches our part’s ±0.03mm tolerance for engine brackets?

Q3: What if our die casting machine is a 300T Yizumi (older model) — will the mold be compatible?

Q4: How long will the anti-adhesion coating last, and can we reapply it ourselves?