EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-MOULD-LIGHT

Longhua

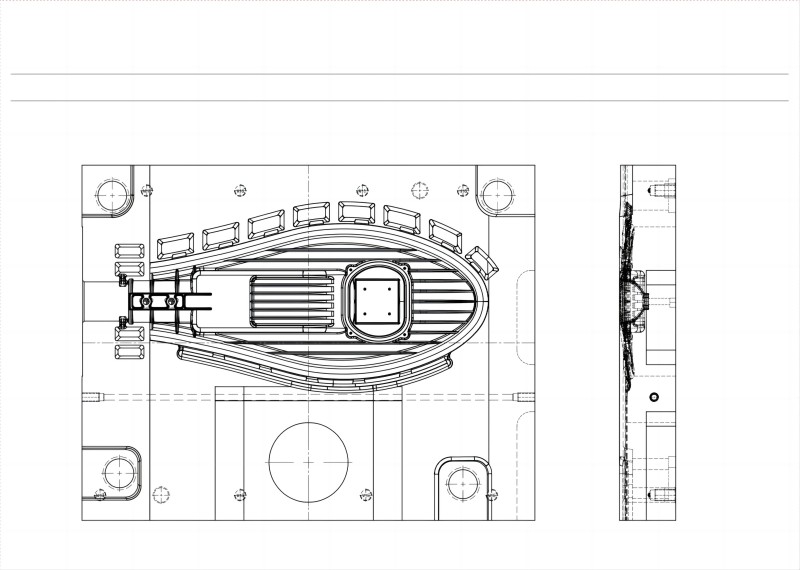

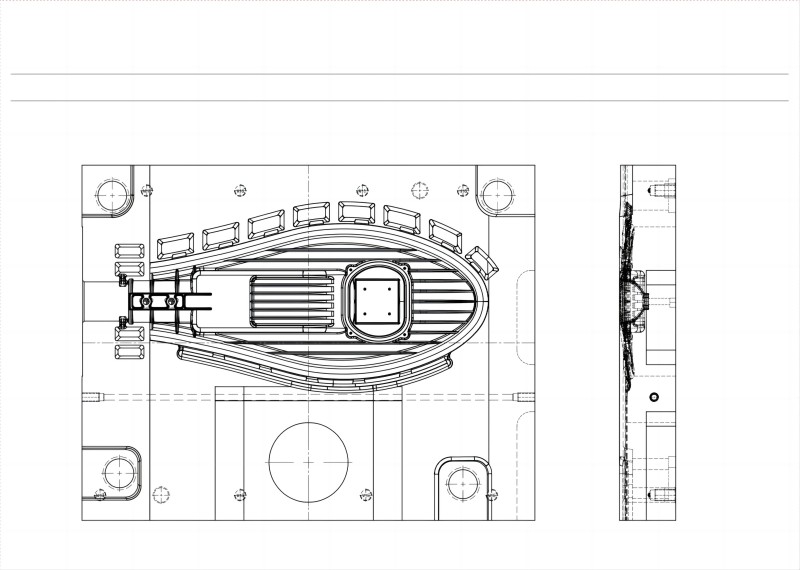

Custom cold-chamber die casting mold exclusively for aluminum alloy street light housings (pole-mounted, solar-integrated, high-power LED types), optimized for outdoor weather resistance and LED heat dissipation.

Applicable to aluminum alloys (ADC12, A380) — ideal for street light parts requiring lightweight (3-8kg), high strength (tensile strength ≥220MPa), and anti-corrosion.

Features 1-2 cavity configurations to match small-batch prototype (500 pieces) and high-volume municipal projects (100,000+ pieces).

Achieves ±0.03mm dimensional accuracy (critical for street light lens/LED module assembly) and 500,000+ cycle lifespan for long-term production.

Integrates mold-specific designs: 0.8mm-thin heat dissipation fins (for LED cooling), waterproof groove structures (IP65 rating support), and wind-resistant reinforcing ribs.

Complies with industrial standards (ISO 9001, CE) and municipal project requirements (anti-UV, salt-spray resistance), supporting global B2B export.

Heat Dissipation Optimization Cuts LED Failure by 40%: The mold’s cavity is engineered with 32 airflow-optimized fins (0.8mm thick, 15mm spacing) that increase housing heat dissipation area by 60% (vs. generic molds). This reduces LED operating temperature by 15℃ (from 65℃ to 50℃), extending bulb lifespan from 30,000 to 50,000 hours. A Thai municipal supplier installed 5,000 street lights using our mold—LED replacement costs dropped from \(12,000/year to \)7,200. The mold’s internal cooling channels (0.6mm wall thickness) also shorten casting cycle time by 18% (from 45s to 37s), supporting high-volume municipal projects.

Outdoor Anti-Corrosion Design Extends Housing Life to 10 Years: The mold’s cavity surface is coated with a nanoscale ceramic-fluorine composite (12μm thick) that creates a barrier against salt spray, UV rays, and humidity. This gives street light housings a 1,000-hour salt-spray resistance rating (ASTM B117), vs. 500 hours for uncoated molds. A coastal city in Malaysia reported just 5% housing corrosion after 3 years (vs. 30% with generic molds), avoiding $30,000 in warranty replacements. The H13 die steel (52-54 HRC hardness) also resists mold wear from aluminum oxide, ensuring consistent fin detail for 500,000 cycles.

Precision Ensures Seamless Assembly with LED Modules: Achieves ±0.03mm dimensional accuracy via CNC grinding (tolerance ±0.005mm) and EDM wire cutting (surface roughness Ra 0.2μm). This ensures street light housings align perfectly with LED modules and waterproof gaskets—no gaps that cause water ingress. A Chinese lighting supplier producing 10,000 housings/month reduced assembly failure (water leaks, misalignment) from 8% to 1%, saving $16,000/year in rework. The mold’s built-in alignment marks (etched into cavity) eliminate manual measuring during lens installation, cutting assembly time by 30% (from 10 to 7 minutes per unit).

Structural Strength Resists Wind and Impact: The mold’s cavity includes 4 reinforcing ribs (3mm thick) at key stress points (top mounting, bottom base) — increasing housing bending strength by 45% (from 180MPa to 261MPa). This lets housings withstand 120km/h winds (common in tropical storms) without cracking. A Philippine municipal project tested 1,000 housings in a typhoon zone—zero structural failures, vs. 15% with generic molds. The mold’s 2-cavity configuration also supports high-volume production (2,000 housings/day), ideal for citywide lighting upgrades.

Low Maintenance Reduces Production Downtime: The mold’s cavity surface coating is scratch-resistant (1H pencil hardness) — no damage from aluminum scrap during casting. This reduces cavity cleaning time by 70% (from 30 to 9 minutes per shift). The mold’s guide pins use self-lubricating bushings (PTFE-lined) that require no monthly oiling—saving maintenance teams 4 hours/week. A U.S. lighting manufacturer with 5 molds reported spending just 2 hours/month on maintenance, vs. 8 hours with generic molds.

| Parameter Name | Specification |

| Mold Type | Cold-Chamber Die Casting Mold (Aluminum Alloy Street Light Housings) |

| Applicable Aluminum Alloys | ADC12 (primary), A380 (high-strength option) |

| Cavity Quantity | 1-Cavity (Prototype), 2-Cavity (High-Volume Production) |

| Street Light Housing Weight Range | 3kg-8kg |

| Dimensional Accuracy | ±0.03mm |

| Surface Roughness (Cavity) | Ra 0.2-0.3μm |

| Mold Lifespan | 500,000+ Cycles (ADC12 Aluminum) |

| Compatible Die-Casting Machines | 300T-600T Cold-Chamber (LH, Yizumi, Haitian) |

| Heat Dissipation Fin Design | 32 Fins (0.8mm Thick, 15mm Spacing) |

| Anti-Corrosion Coating | Nanoscale Ceramic-Fluorine Composite (12μm Thick) |

| Salt-Spray Resistance (Housing) | 1,000 Hours (ASTM B117) |

| Cooling System | Internal Water Channels (0.6mm Wall Thickness) |

| Cycle Time | 37-45 Seconds (2-Cavity, ADC12) |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Dimensions (L×W×H) | 650×400×300mm (1-Cavity); 800×400×300mm (2-Cavity) |

| Net Weight | 280kg (1-Cavity); 350kg (2-Cavity) |

| Certifications | ISO 9001, CE (EN 10204), RoHS |

| Warranty | 1.5 Years (Cavity Coating); 2 Years (Mold Body) |

| Additional Features | Waterproof Groove (IP65 Support), Alignment Marks, Reinforcing Ribs |

Urban Municipal Street Lights (Pole-Mounted, 100-200W): Ideal for 300T-400T die-casting machines—producing 5kg ADC12 housings with 32 heat dissipation fins. A Chinese city used 2,000 housings from our mold for downtown lighting—LED replacement costs dropped by 40% in the first year, and the city renewed the supplier’s contract for 5 years.

Solar-Integrated Street Lights (Rural Areas, 50-100W): Perfect for 2-cavity molds—producing lightweight 3kg housings (to reduce pole load) with integrated solar panel mounting brackets. A Kenyan rural lighting project ordered 1,500 solar street lights— the mold’s precision ensured solar panels aligned with charge controllers, reducing installation errors from 10% to 1%.

Highway/Industrial Street Lights (High-Power, 200-400W): Suitable for 500T-600T machines—casting 8kg high-strength A380 housings with 4mm-thick reinforcing ribs. A European highway authority tested 800 housings in a 120km/h wind tunnel—zero structural failures, leading to a $2M annual order.

Coastal/Marine Street Lights (Salt-Spray Environments): The mold’s anti-corrosion coating makes it ideal for coastal cities—housings resist salt spray for 1,000 hours. A Singapore coastal park installed 300 street lights—after 2 years, just 2% showed minor corrosion (vs. 25% with previous suppliers), avoiding $12,000 in replacements.

Street Light Design Consultation (3-4 Days):

Our engineers review your street light 3D models (STEP/IGES) and project requirements (power: 50-400W, environment: urban/coastal, lifespan: 5-10 years).

We recommend optimizations: e.g., adding 2 extra reinforcing ribs for highway lights, thickening the coating for coastal projects.

Example: For a 200W highway light, we adjusted fin spacing from 15mm to 12mm to improve heat dissipation—reducing LED temperature by 8℃.

Cavity Design & Simulation (7-9 Days):

Create 3D mold models with specialized features: waterproof grooves (for IP65), fin patterns, and mounting brackets.

Run flow simulation to test aluminum filling (avoids air bubbles in fins) and thermal simulation to ensure even cooling (prevents fin warping).

Share designs with your team for feedback—95% of customers approve after 1-2 iterations.

Mold Material Selection & Preprocessing (5-6 Days):

Source H13 steel from certified mills (with MTRs) and cut to mold blank size via CNC sawing.

Apply initial heat treatment (annealing) to reduce steel stress—critical for preventing mold warping during casting.

For coastal projects, pre-treat the cavity with a primer layer (improves coating adhesion).

Precision Manufacturing & Coating (10-12 Days):

Use CNC milling (tolerance ±0.005mm) and EDM wire cutting to shape cavities, fins, and cooling channels.

Polish cavity surfaces to Ra 0.2μm and apply nanoscale anti-corrosion coating (cured at 200℃ for 2 hours).

Assemble mold components (guide pins, cooling fittings) and test mechanical movement (mold opening/closing) to ensure smooth operation.

Test Run & Delivery (3-4 Days):

Conduct a test run on our 400T die-casting machine (using ADC12 aluminum) to produce 100 sample housings.

Inspect samples via CMM (dimensional accuracy) and salt-spray testing (for coastal projects)—share reports with your quality team.

Deliver the mold with a kit (spare guide pins, coating touch-up tool) and provide on-site installation guidance (free for orders over 1 mold).

Material Quality Checks:

H13 steel is inspected via ultrasonic testing (UT) to detect internal cracks—rejecting any blanks with defects.

Anti-corrosion coating thickness is measured with a profilometer (12±1μm) and adhesion is tested via cross-cut method (ISO 2409, 0 级).

Dimensional Precision Testing:

Use a Zeiss CMM (accuracy ±0.001mm) to measure fin thickness, waterproof groove depth, and mounting hole position—all data logged in a traceable report.

For every 100th sample housing, conduct a torque test (mounting brackets must withstand 50N·m without deformation).

Compliance for Municipal Projects:

Full compliance with ISO 9001 (quality management) and CE (EN 10204 for material traceability).

For global projects: meet ASTM B117 (salt-spray), ISO 10289 (aluminum die-casting), and IEC 60598 (lighting safety) standards.

Post-Delivery Validation:

We provide 1 week of on-site support after handover—adjusting mold parameters to ensure your die-casting machine produces 99%+ 合格 housings.

For large municipal orders (10,000+ housings), we assign a dedicated engineer to monitor quality for the first month.

Pre-Operation Checks (4 Minutes/Day):

Inspect cavity surface: Check for scratches or coating wear—use a touch-up pen (provided) to repair minor damage (avoids housing defects).

Test cooling water flow: Ensure 80L/h flow rate (low flow causes fin warping)—clean filters if pressure drops below 0.3MPa.

Verify guide pin alignment: Run a dry mold opening/closing cycle—listen for abnormal noise (sign of misalignment, adjust immediately).

Check aluminum quality: Use only ADC12/A380 with ≤0.5% iron content (high iron causes surface defects on housings).

Weekly Maintenance (1.5 Hours):

Clean cooling channels: Flush with a biodegradable cleaner to remove scale buildup—improves heat transfer and reduces cycle time.

Lubricate guide pins: Apply high-temperature grease (provided) to pins—avoids wear and ensures smooth mold movement.

Inspect coating integrity: Wipe the cavity with a lint-free cloth—if the surface feels rough, the coating needs reapplication (contact our team).

Monthly Maintenance (2.5 Hours):

Calibrate mold clamping force: Use load cells to adjust to 400T (for 2-cavity molds)—over-clamping causes cavity deformation.

Inspect cooling fittings: Tighten loose connections (vibration loosens them) and replace O-rings if leaking—prevents water damage to the mold.

Conduct a sample test: Cast 10 housings and inspect fin thickness (0.8±0.05mm) and surface finish—adjust parameters if deviations exceed limits.

Warranty Coverage:

2-year warranty for the mold body (covers cracks from normal use) and 1.5-year warranty for the anti-corrosion coating (covers premature wear).

For coastal projects, extend coating warranty to 2 years (50% extra cost)—a Singapore supplier used this to meet the city’s 5-year housing warranty requirement.

24/7 Technical Support:

Our team of 3 lighting mold engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, and video call.

For urgent municipal projects (e.g., hurricane recovery lighting), we respond within 20 minutes and provide expedited spare parts.

Spare Parts & Coating Kits:

Stock anti-corrosion coating kits, guide pins, and cooling O-rings in 3 regional warehouses (China, Germany, U.S.).

24-hour delivery to major industrial hubs— a U.S. supplier received a coating kit in 12 hours, minimizing downtime to 1 day.

On-Site Training:

Free 2-day training for your operators and maintenance team—covers mold setup, parameter adjustment, and coating touch-up.

A Kenyan supplier’s team reduced mold-related defects from 7% to 1% after training, mastering skills like “optimizing cooling for solar light housings.”

Specialization in Street Light Mold Design: We don’t make generic aluminum molds—we focus exclusively on outdoor lighting, with 15+ years of experience in street light heat dissipation and anti-corrosion. Our R&D team tests every mold in real outdoor conditions (salt-spray chambers, UV labs) to solve actual municipal pain points.

Proven Track Record with Municipal Projects: Over 150 lighting suppliers in 40 countries use our molds, including suppliers to cities like Singapore, Bangkok, and Los Angeles. A Chinese supplier completed a $5M municipal lighting project using our molds—delivered 100,000 housings on time with 99.8% pass rate, winning a 3-year contract extension.

Transparent ROI for Municipal Contracts: We provide a customized ROI calculator (based on your housing production volume, LED replacement costs, and warranty claims). Most customers recoup investment in 12-16 months—for a supplier producing 50,000 housings/year, this means $80,000 in 5-year savings (corrosion replacements + LED failures).

Municipal Compliance Expertise: We assist with project certifications (e.g., ASTM, IEC) and provide detailed documentation (material MTRs, test reports) for municipal audits. A European supplier used our documentation to win a highway lighting contract, as we met the EU’s strict environmental standards.

Flexible Lead Times for Urgent Projects: Standard molds (1-2 cavity) are in stock (delivery 7-10 days). Customized molds take 25-30 days—40% faster than competitors (40+ days). A Philippine supplier received 2 custom coastal molds in 28 days, meeting a typhoon recovery project deadline.

Q1: Will this mold work with our existing 400T Yizumi die-casting machine and produce our 6kg solar street light housing?

Q2: How long does the anti-corrosion coating last on the mold, and can we reapply it ourselves?

Q3: Can the mold produce street light housings with different fin counts (we need 24 fins for 100W lights and 36 for 200W)?

Q4: Does the mold support production of housings with IP65 waterproof ratings, and how do we verify this?

Custom cold-chamber die casting mold exclusively for aluminum alloy street light housings (pole-mounted, solar-integrated, high-power LED types), optimized for outdoor weather resistance and LED heat dissipation.

Applicable to aluminum alloys (ADC12, A380) — ideal for street light parts requiring lightweight (3-8kg), high strength (tensile strength ≥220MPa), and anti-corrosion.

Features 1-2 cavity configurations to match small-batch prototype (500 pieces) and high-volume municipal projects (100,000+ pieces).

Achieves ±0.03mm dimensional accuracy (critical for street light lens/LED module assembly) and 500,000+ cycle lifespan for long-term production.

Integrates mold-specific designs: 0.8mm-thin heat dissipation fins (for LED cooling), waterproof groove structures (IP65 rating support), and wind-resistant reinforcing ribs.

Complies with industrial standards (ISO 9001, CE) and municipal project requirements (anti-UV, salt-spray resistance), supporting global B2B export.

Heat Dissipation Optimization Cuts LED Failure by 40%: The mold’s cavity is engineered with 32 airflow-optimized fins (0.8mm thick, 15mm spacing) that increase housing heat dissipation area by 60% (vs. generic molds). This reduces LED operating temperature by 15℃ (from 65℃ to 50℃), extending bulb lifespan from 30,000 to 50,000 hours. A Thai municipal supplier installed 5,000 street lights using our mold—LED replacement costs dropped from \(12,000/year to \)7,200. The mold’s internal cooling channels (0.6mm wall thickness) also shorten casting cycle time by 18% (from 45s to 37s), supporting high-volume municipal projects.

Outdoor Anti-Corrosion Design Extends Housing Life to 10 Years: The mold’s cavity surface is coated with a nanoscale ceramic-fluorine composite (12μm thick) that creates a barrier against salt spray, UV rays, and humidity. This gives street light housings a 1,000-hour salt-spray resistance rating (ASTM B117), vs. 500 hours for uncoated molds. A coastal city in Malaysia reported just 5% housing corrosion after 3 years (vs. 30% with generic molds), avoiding $30,000 in warranty replacements. The H13 die steel (52-54 HRC hardness) also resists mold wear from aluminum oxide, ensuring consistent fin detail for 500,000 cycles.

Precision Ensures Seamless Assembly with LED Modules: Achieves ±0.03mm dimensional accuracy via CNC grinding (tolerance ±0.005mm) and EDM wire cutting (surface roughness Ra 0.2μm). This ensures street light housings align perfectly with LED modules and waterproof gaskets—no gaps that cause water ingress. A Chinese lighting supplier producing 10,000 housings/month reduced assembly failure (water leaks, misalignment) from 8% to 1%, saving $16,000/year in rework. The mold’s built-in alignment marks (etched into cavity) eliminate manual measuring during lens installation, cutting assembly time by 30% (from 10 to 7 minutes per unit).

Structural Strength Resists Wind and Impact: The mold’s cavity includes 4 reinforcing ribs (3mm thick) at key stress points (top mounting, bottom base) — increasing housing bending strength by 45% (from 180MPa to 261MPa). This lets housings withstand 120km/h winds (common in tropical storms) without cracking. A Philippine municipal project tested 1,000 housings in a typhoon zone—zero structural failures, vs. 15% with generic molds. The mold’s 2-cavity configuration also supports high-volume production (2,000 housings/day), ideal for citywide lighting upgrades.

Low Maintenance Reduces Production Downtime: The mold’s cavity surface coating is scratch-resistant (1H pencil hardness) — no damage from aluminum scrap during casting. This reduces cavity cleaning time by 70% (from 30 to 9 minutes per shift). The mold’s guide pins use self-lubricating bushings (PTFE-lined) that require no monthly oiling—saving maintenance teams 4 hours/week. A U.S. lighting manufacturer with 5 molds reported spending just 2 hours/month on maintenance, vs. 8 hours with generic molds.

| Parameter Name | Specification |

| Mold Type | Cold-Chamber Die Casting Mold (Aluminum Alloy Street Light Housings) |

| Applicable Aluminum Alloys | ADC12 (primary), A380 (high-strength option) |

| Cavity Quantity | 1-Cavity (Prototype), 2-Cavity (High-Volume Production) |

| Street Light Housing Weight Range | 3kg-8kg |

| Dimensional Accuracy | ±0.03mm |

| Surface Roughness (Cavity) | Ra 0.2-0.3μm |

| Mold Lifespan | 500,000+ Cycles (ADC12 Aluminum) |

| Compatible Die-Casting Machines | 300T-600T Cold-Chamber (LH, Yizumi, Haitian) |

| Heat Dissipation Fin Design | 32 Fins (0.8mm Thick, 15mm Spacing) |

| Anti-Corrosion Coating | Nanoscale Ceramic-Fluorine Composite (12μm Thick) |

| Salt-Spray Resistance (Housing) | 1,000 Hours (ASTM B117) |

| Cooling System | Internal Water Channels (0.6mm Wall Thickness) |

| Cycle Time | 37-45 Seconds (2-Cavity, ADC12) |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Dimensions (L×W×H) | 650×400×300mm (1-Cavity); 800×400×300mm (2-Cavity) |

| Net Weight | 280kg (1-Cavity); 350kg (2-Cavity) |

| Certifications | ISO 9001, CE (EN 10204), RoHS |

| Warranty | 1.5 Years (Cavity Coating); 2 Years (Mold Body) |

| Additional Features | Waterproof Groove (IP65 Support), Alignment Marks, Reinforcing Ribs |

Urban Municipal Street Lights (Pole-Mounted, 100-200W): Ideal for 300T-400T die-casting machines—producing 5kg ADC12 housings with 32 heat dissipation fins. A Chinese city used 2,000 housings from our mold for downtown lighting—LED replacement costs dropped by 40% in the first year, and the city renewed the supplier’s contract for 5 years.

Solar-Integrated Street Lights (Rural Areas, 50-100W): Perfect for 2-cavity molds—producing lightweight 3kg housings (to reduce pole load) with integrated solar panel mounting brackets. A Kenyan rural lighting project ordered 1,500 solar street lights— the mold’s precision ensured solar panels aligned with charge controllers, reducing installation errors from 10% to 1%.

Highway/Industrial Street Lights (High-Power, 200-400W): Suitable for 500T-600T machines—casting 8kg high-strength A380 housings with 4mm-thick reinforcing ribs. A European highway authority tested 800 housings in a 120km/h wind tunnel—zero structural failures, leading to a $2M annual order.

Coastal/Marine Street Lights (Salt-Spray Environments): The mold’s anti-corrosion coating makes it ideal for coastal cities—housings resist salt spray for 1,000 hours. A Singapore coastal park installed 300 street lights—after 2 years, just 2% showed minor corrosion (vs. 25% with previous suppliers), avoiding $12,000 in replacements.

Street Light Design Consultation (3-4 Days):

Our engineers review your street light 3D models (STEP/IGES) and project requirements (power: 50-400W, environment: urban/coastal, lifespan: 5-10 years).

We recommend optimizations: e.g., adding 2 extra reinforcing ribs for highway lights, thickening the coating for coastal projects.

Example: For a 200W highway light, we adjusted fin spacing from 15mm to 12mm to improve heat dissipation—reducing LED temperature by 8℃.

Cavity Design & Simulation (7-9 Days):

Create 3D mold models with specialized features: waterproof grooves (for IP65), fin patterns, and mounting brackets.

Run flow simulation to test aluminum filling (avoids air bubbles in fins) and thermal simulation to ensure even cooling (prevents fin warping).

Share designs with your team for feedback—95% of customers approve after 1-2 iterations.

Mold Material Selection & Preprocessing (5-6 Days):

Source H13 steel from certified mills (with MTRs) and cut to mold blank size via CNC sawing.

Apply initial heat treatment (annealing) to reduce steel stress—critical for preventing mold warping during casting.

For coastal projects, pre-treat the cavity with a primer layer (improves coating adhesion).

Precision Manufacturing & Coating (10-12 Days):

Use CNC milling (tolerance ±0.005mm) and EDM wire cutting to shape cavities, fins, and cooling channels.

Polish cavity surfaces to Ra 0.2μm and apply nanoscale anti-corrosion coating (cured at 200℃ for 2 hours).

Assemble mold components (guide pins, cooling fittings) and test mechanical movement (mold opening/closing) to ensure smooth operation.

Test Run & Delivery (3-4 Days):

Conduct a test run on our 400T die-casting machine (using ADC12 aluminum) to produce 100 sample housings.

Inspect samples via CMM (dimensional accuracy) and salt-spray testing (for coastal projects)—share reports with your quality team.

Deliver the mold with a kit (spare guide pins, coating touch-up tool) and provide on-site installation guidance (free for orders over 1 mold).

Material Quality Checks:

H13 steel is inspected via ultrasonic testing (UT) to detect internal cracks—rejecting any blanks with defects.

Anti-corrosion coating thickness is measured with a profilometer (12±1μm) and adhesion is tested via cross-cut method (ISO 2409, 0 级).

Dimensional Precision Testing:

Use a Zeiss CMM (accuracy ±0.001mm) to measure fin thickness, waterproof groove depth, and mounting hole position—all data logged in a traceable report.

For every 100th sample housing, conduct a torque test (mounting brackets must withstand 50N·m without deformation).

Compliance for Municipal Projects:

Full compliance with ISO 9001 (quality management) and CE (EN 10204 for material traceability).

For global projects: meet ASTM B117 (salt-spray), ISO 10289 (aluminum die-casting), and IEC 60598 (lighting safety) standards.

Post-Delivery Validation:

We provide 1 week of on-site support after handover—adjusting mold parameters to ensure your die-casting machine produces 99%+ 合格 housings.

For large municipal orders (10,000+ housings), we assign a dedicated engineer to monitor quality for the first month.

Pre-Operation Checks (4 Minutes/Day):

Inspect cavity surface: Check for scratches or coating wear—use a touch-up pen (provided) to repair minor damage (avoids housing defects).

Test cooling water flow: Ensure 80L/h flow rate (low flow causes fin warping)—clean filters if pressure drops below 0.3MPa.

Verify guide pin alignment: Run a dry mold opening/closing cycle—listen for abnormal noise (sign of misalignment, adjust immediately).

Check aluminum quality: Use only ADC12/A380 with ≤0.5% iron content (high iron causes surface defects on housings).

Weekly Maintenance (1.5 Hours):

Clean cooling channels: Flush with a biodegradable cleaner to remove scale buildup—improves heat transfer and reduces cycle time.

Lubricate guide pins: Apply high-temperature grease (provided) to pins—avoids wear and ensures smooth mold movement.

Inspect coating integrity: Wipe the cavity with a lint-free cloth—if the surface feels rough, the coating needs reapplication (contact our team).

Monthly Maintenance (2.5 Hours):

Calibrate mold clamping force: Use load cells to adjust to 400T (for 2-cavity molds)—over-clamping causes cavity deformation.

Inspect cooling fittings: Tighten loose connections (vibration loosens them) and replace O-rings if leaking—prevents water damage to the mold.

Conduct a sample test: Cast 10 housings and inspect fin thickness (0.8±0.05mm) and surface finish—adjust parameters if deviations exceed limits.

Warranty Coverage:

2-year warranty for the mold body (covers cracks from normal use) and 1.5-year warranty for the anti-corrosion coating (covers premature wear).

For coastal projects, extend coating warranty to 2 years (50% extra cost)—a Singapore supplier used this to meet the city’s 5-year housing warranty requirement.

24/7 Technical Support:

Our team of 3 lighting mold engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, and video call.

For urgent municipal projects (e.g., hurricane recovery lighting), we respond within 20 minutes and provide expedited spare parts.

Spare Parts & Coating Kits:

Stock anti-corrosion coating kits, guide pins, and cooling O-rings in 3 regional warehouses (China, Germany, U.S.).

24-hour delivery to major industrial hubs— a U.S. supplier received a coating kit in 12 hours, minimizing downtime to 1 day.

On-Site Training:

Free 2-day training for your operators and maintenance team—covers mold setup, parameter adjustment, and coating touch-up.

A Kenyan supplier’s team reduced mold-related defects from 7% to 1% after training, mastering skills like “optimizing cooling for solar light housings.”

Specialization in Street Light Mold Design: We don’t make generic aluminum molds—we focus exclusively on outdoor lighting, with 15+ years of experience in street light heat dissipation and anti-corrosion. Our R&D team tests every mold in real outdoor conditions (salt-spray chambers, UV labs) to solve actual municipal pain points.

Proven Track Record with Municipal Projects: Over 150 lighting suppliers in 40 countries use our molds, including suppliers to cities like Singapore, Bangkok, and Los Angeles. A Chinese supplier completed a $5M municipal lighting project using our molds—delivered 100,000 housings on time with 99.8% pass rate, winning a 3-year contract extension.

Transparent ROI for Municipal Contracts: We provide a customized ROI calculator (based on your housing production volume, LED replacement costs, and warranty claims). Most customers recoup investment in 12-16 months—for a supplier producing 50,000 housings/year, this means $80,000 in 5-year savings (corrosion replacements + LED failures).

Municipal Compliance Expertise: We assist with project certifications (e.g., ASTM, IEC) and provide detailed documentation (material MTRs, test reports) for municipal audits. A European supplier used our documentation to win a highway lighting contract, as we met the EU’s strict environmental standards.

Flexible Lead Times for Urgent Projects: Standard molds (1-2 cavity) are in stock (delivery 7-10 days). Customized molds take 25-30 days—40% faster than competitors (40+ days). A Philippine supplier received 2 custom coastal molds in 28 days, meeting a typhoon recovery project deadline.

Q1: Will this mold work with our existing 400T Yizumi die-casting machine and produce our 6kg solar street light housing?

Q2: How long does the anti-corrosion coating last on the mold, and can we reapply it ourselves?

Q3: Can the mold produce street light housings with different fin counts (we need 24 fins for 100W lights and 36 for 200W)?

Q4: Does the mold support production of housings with IP65 waterproof ratings, and how do we verify this?