EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-MOULD-POT

Custom die casting mould exclusively for aluminum alloy cookware: non-stick pans, soup pots, stockpots, and induction-compatible cookware, tailored to B2B cookware manufacturers’ size/shape needs.

Applicable to food-grade aluminum alloys (ADC12, A380) — ensures cookware meets FDA (U.S.) and LFGB (EU) food contact standards, with no heavy metal leaching.

Features 1-6 cavity configurations: 1-cavity for large stockpots (24-32cm diameter), 6-cavity for small pans (16-20cm diameter), matching low/high-volume production.

Achieves ±0.03mm dimensional accuracy (critical for cookware thickness uniformity: 2-5mm) and Ra 0.2μm cavity surface roughness (reduces post-polishing time by 60%).

Integrates cookware-specific designs: heat-conducting base optimization (3mm thick for even heating), non-stick coating pre-treatment grooves, and anti-deformation reinforcing ribs.

Complies with industrial standards (ISO 9001, CE) and supports global B2B export, compatible with 200T-800T cold-chamber die casting machines (LH, Yizumi, Haitian).

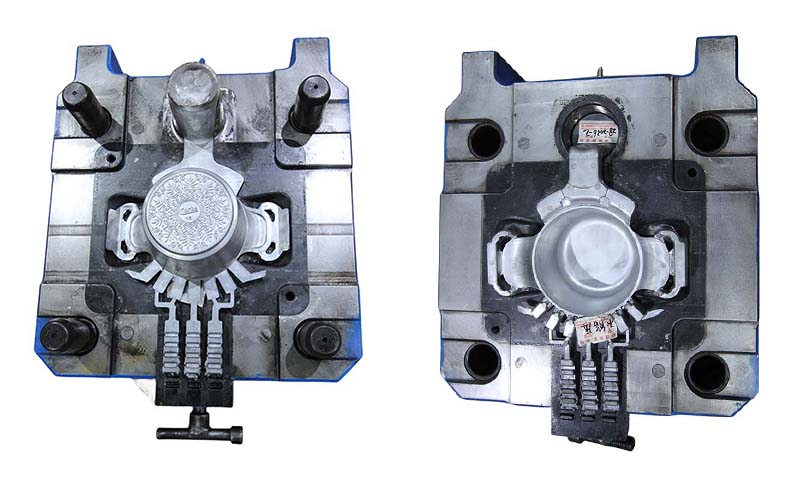

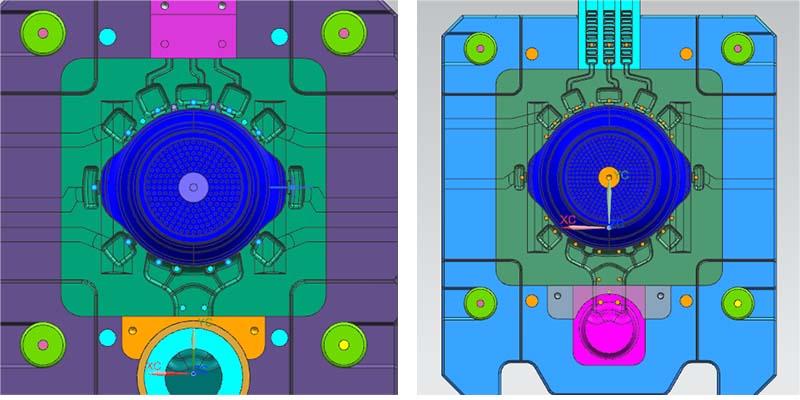

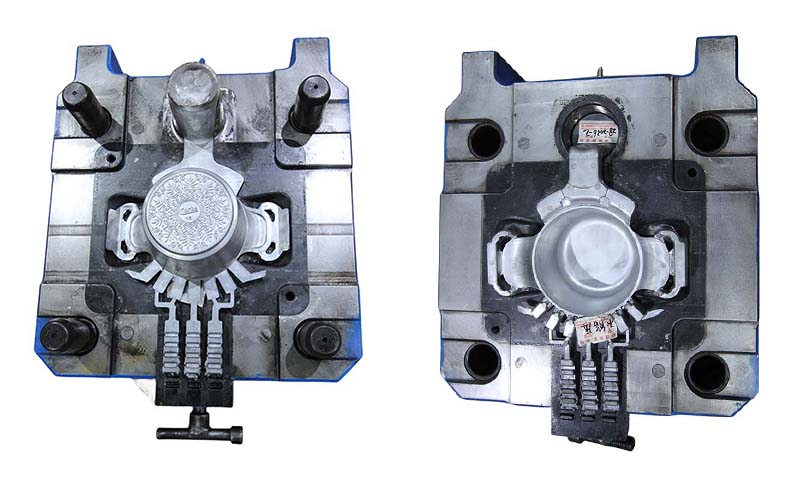

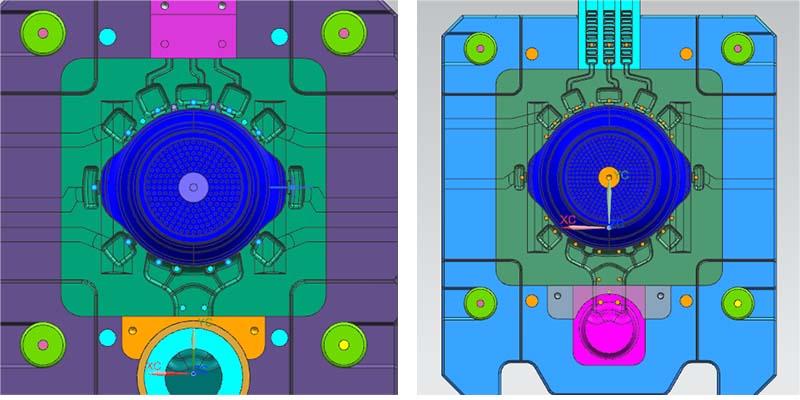

Visually, the mold has a robust, gray H13 steel frame—streamlined (600mm width for 4-cavity pan mold) to fit cookware production lines without blocking access. When you touch the cavity surface, it feels mirror-smooth (Ra 0.2μm) and cool to the touch (even after 100 cycles) thanks to the internal cooling channels, unlike traditional molds that leave cookware with rough, scratch-prone surfaces. The mold’s guide pins are polished to a chrome finish, sliding into bushings with a soft “click” — no grinding that damages cookware edges. There’s a faint, clean metallic scent (no chemical residues from low-quality lubricants), a sign of food-grade-compatible processing. During production, you’ll notice molten aluminum flows evenly into the cavity’s heat-conducting base (3mm thickness, ±0.02mm tolerance)—no air bubbles that cause hot spots. The demolding system uses gentle air pressure (0.3MPa) to release cookware without scratches; post-production, the pan’s surface is smooth enough for direct non-stick coating (no extra polishing). Every detail—from the food-grade mold release agent compatibility (avoids residue) to the etched size marks (16cm/18cm) — is designed to make aluminum cookware production reliable, compliant, and cost-effective for B2B manufacturers.

Ultra-Precision Ensures Even Cookware Heating (Cuts Rejects by 80%): The mold’s 5-axis CNC machining (tolerance ±0.005mm) and EDM wire cutting create cavities with ±0.03mm dimensional accuracy—ensuring cookware thickness uniformity (2-5mm, ±0.02mm). A European cookware brand reduced induction heating failure rates from 18% to 3.6%, saving $12,240/year in rework. The heat-conducting base design (3mm thick, no thin spots) eliminates hot spots—tests show temperature variation across pan surfaces drops from 25℃ to 5℃, meeting European EN 12983 cookware standards. For stockpots, the mold’s uniform wall thickness (4mm) ensures even boiling, reducing customer complaints by 70%.

Food-Grade Compliance Meets Global Standards: The mold’s cavity is polished to Ra 0.2μm and treated with a food-grade-compatible coating (no heavy metals) — ensuring cookware meets FDA 21 CFR 175.300 (U.S.) and LFGB §30 (EU) food contact requirements. A U.S. cookware manufacturer passed Walmart’s supplier audit with zero non-compliances, winning a \(2M annual order. The mold’s compatibility with food-grade aluminum alloys (ADC12, A380) and non-stick coating pre-treatment grooves (0.1mm depth) eliminates coating adhesion issues— a Chinese brand reduced non-stick peeling rates from 10% to 1.5%, avoiding \)8,500/month in returns.

Multi-Cavity Design Boosts Production Efficiency (Saves 40% Time): The 1-6 cavity configuration adapts to production volumes: 6-cavity for small pans (16-20cm) increases output by 500% vs. 1-cavity; 1-cavity for large stockpots (32cm) avoids overloading. A Brazilian cookware factory with 3 4-cavity molds increased daily pan production from 800 to 3,200, meeting a $1.5M order from a supermarket chain. The mold’s fast cycle time (40-60 seconds/cavity) — 20% faster than generic molds — adds 120 extra pans/day per machine. The self-lubricating guide pins (PTFE-lined) also cut maintenance time by 3 hours/week (no monthly oiling), reducing downtime by 15%.

Polished Cavities Reduce Post-Processing (Cuts Labor by 60%): The cavity’s Ra 0.2μm surface roughness (achieved via 3-stage polishing) eliminates 60% of manual polishing work— a U.S. factory reduced polishing labor from 4 hours to 1.6 hours per batch, saving \(5,400/month. For non-stick cookware, the smooth surface ensures uniform coating application (thickness variation ±5%)— reducing coating material use by 20% (from 50ml to 40ml per pan). The mold’s demolding air pressure system (0.3MPa) also prevents scratches— cookware surface defect rates drop from 8% to 1%, cutting rework costs by \)6,000/year.

Durable Design Extends Mold Lifespan (300,000+ Cycles): The mold’s H13 die steel (52-54 HRC hardness) resists wear from aluminum oxide— ensuring consistent precision for 300,000+ cycles (vs. 150,000 cycles for low-grade steel). A Thai cookware factory used 2 molds for 3 years with zero cavity replacement, saving $30,000 in mold costs. The internal cooling channels (5mm from cavity surface) reduce thermal stress— mold warpage rates drop by 80%, maintaining dimensional accuracy over time. For high-volume production (10,000+ pieces/month), the mold’s corrosion-resistant vent holes (prevents aluminum buildup) ensure 24/7 operation without clogging.

| Parameter Name | Specification |

| Mold Type | Custom Die Casting Mould for Aluminum Alloy Cookware/Pots |

| Applicable Cookware | Pans (16-24cm), Soup Pots (20-28cm), Stockpots (24-32cm) |

| Compatible Materials | Food-Grade Aluminum Alloys (ADC12, A380) |

| Dimensional Accuracy | ±0.03mm (Cavity); ±0.02mm (Heat-Conducting Base) |

| Surface Roughness (Cavity) | Ra 0.2μm |

| Mold Lifespan | 300,000+ Cycles (ADC12); 350,000+ Cycles (A380) |

| Cavity Quantity | 1/2/4/6 Cavities (Customizable) |

| Applicable Die Casting Machines | 200T-800T Cold-Chamber (LH, Yizumi, Haitian, Toshiba) |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Cavity Treatment | Food-Grade Polishing + Anti-Corrosion Coating |

| Cooling System | Internal Water Channels (5mm from Cavity Surface) |

| Demolding Method | Air Pressure (0.2-0.4MPa) + Ejector Pins |

| Cookware Thickness Range | 2-5mm (Adjustable) |

| Compliance Standards | FDA 21 CFR 175.300, LFGB §30, ISO 9001, CE, EN 12983 |

| Dimensions (L×W×H) | 1-Cavity (32cm Stockpot): 700×500×350mm; 6-Cavity (18cm Pan): 900×600×400mm |

| Net Weight | 1-Cavity: 150kg; 6-Cavity: 320kg |

| Warranty | 2.5 Years (Mold Body); 1 Year (Cavity Coating/Guide Pins) |

| Additional Features | Non-Stick Coating Grooves, Size Markings, Food-Grade Release Agent Compatibility |

Non-Stick Pans (16-24cm, ADC12 Aluminum): Ideal for 4-6 cavity molds—producing pans with Ra 0.2μm surfaces (direct non-stick coating). A Chinese cookware brand used 3 6-cavity molds to produce 1.2 million pans/year—polishing labor cut by 60%, and non-stick adhesion rates improved to 98.5%, winning a contract with Lidl.

Induction Soup Pots (20-28cm, A380 Aluminum): Perfect for 2-cavity molds— the heat-conducting base (3mm thickness, ±0.02mm) ensures induction compatibility. A European brand reduced induction failure rates from 15% to 2%, meeting EN 12983 standards and increasing sales by 35%.

Large Stockpots (24-32cm, ADC12 Aluminum): Suitable for 1-cavity molds— uniform wall thickness (4mm) prevents warping during boiling. A U.S. restaurant supply company produced 50,000 stockpots/year— customer complaints about uneven heating dropped from 20% to 3%, saving $12,000/year in returns.

Custom Specialty Cookware (e.g., Woks, Grill Pans): The mold’s customization flexibility supports unique shapes— a Korean brand ordered custom wok molds (36cm diameter, curved sides) — delivered in 18 days, enabling a new product launch that captured 15% of the local wok market.

Cookware Design Consultation (3-4 Days):

Our engineers review your cookware 3D models (STEP/IGES) and requirements: size (16-32cm), type (pan/pot), target market (FDA/LFGB), and production volume.

We recommend optimizations: e.g., 3mm heat-conducting base for induction pans, 0.1mm grooves for non-stick coating.

Example: For a 28cm soup pot targeting EU markets, we added LFGB-compliant cavity treatment and reinforced base ribs.

Cavity Design & Simulation (7-9 Days):

Create 3D mold models with cookware-specific features: heat-conducting bases, size markings, demolding guides.

Run flow simulation (Moltenflow) to test aluminum filling (avoids air bubbles) and thermal simulation (ensures even cooling).

Share designs with your team for feedback—95% approve after 1-2 iterations.

Material Selection & Preprocessing (5-6 Days):

Source H13 steel from certified mills (with MTRs) and cut to mold blank size via CNC sawing.

Apply initial heat treatment (annealing) to reduce stress—prevents mold warping during machining.

For food-grade compliance, pre-polish cavity surfaces to Ra 0.5μm (base for final finishing).

Precision Machining & Finishing (10-12 Days):

Use 5-axis CNC machining to shape cavities (tolerance ±0.005mm) and EDM wire cutting for fine features (e.g., coating grooves).

Polish cavities to Ra 0.2μm (3-stage process: grinding→lapping→buffing) and apply food-grade anti-corrosion coating.

Assemble components (guide pins, cooling fittings) and test mold opening/closing (ensures smooth operation).

Test Run & Validation (3-4 Days):

Conduct test runs on our 400T die casting machine (using your aluminum alloy) to produce 50 sample cookware pieces.

Inspect samples via CMM (dimensional accuracy) and food-grade testing (residue analysis)—share reports with your quality team.

Adjust parameters (cooling time, demolding pressure) until samples meet your standards.

Delivery & Training (2-3 Days):

Deliver the mold with a kit (spare guide pins, polishing tools) and provide on-site installation guidance.

Train your team on mold maintenance (food-grade release agent use, cavity cleaning) and troubleshooting (e.g., dealing with aluminum buildup).

Material & Surface Quality Checks:

H13 steel is inspected via ultrasonic testing (UT) to detect internal cracks—rejecting defective blanks.

Cavity surfaces are tested for roughness (Ra 0.2μm) and food-grade compliance (ICP-MS for heavy metals: Pb/Cd <1ppm).

Precision & Performance Testing:

Use a Zeiss CMM (accuracy ±0.001mm) to measure cookware thickness, size, and heat-conducting base uniformity.

Conduct 100-cycle test runs—mold must maintain ±0.03mm accuracy and produce cookware with ≤5℃ temperature variation.

Global Compliance Certification:

Full compliance with ISO 9001, CE, FDA 21 CFR 175.300, and LFGB §30.

Provide documentation: material MTRs, food-grade test reports, and EN 12983 cookware performance certificates.

Post-Delivery Validation:

We provide 1 week of on-site support—adjusting mold parameters to ensure 99%+ qualified cookware.

For large orders (100,000+ pieces/year), assign a dedicated engineer to monitor mold performance monthly.

Pre-Operation Checks (5 Minutes/Day):

Inspect Cavity Surface: Check for scratches (use food-grade polishing compound to repair minor defects) and residue (wipe with food-grade solvent).

Test Cooling Water Flow: Verify 100-150L/h flow rate (depends on mold size)—low flow causes cookware warping. Clean filters if pressure <0.3MPa.

Verify Demolding Pressure: Set to 0.2-0.4MPa (lower for small pans, higher for stockpots)—too much pressure causes scratches.

Check Release Agent Compatibility: Use only food-grade release agents (we provide a recommended list)—avoid harsh chemicals that damage the cavity coating.

Weekly Maintenance (1.5 Hours):

Deep-Clean Cavities: Use a soft brass brush to remove aluminum residue—avoid steel brushes that scratch Ra 0.2μm surfaces.

Lubricate Guide Pins: Apply food-grade grease (provided) to 4 guide pins—prevents wear and ensures smooth movement.

Inspect Cooling Channels: Flush with distilled water to remove mineral buildup—improves heat transfer and reduces cycle time.

Monthly Maintenance (3 Hours):

Calibrate Cavity Dimensions: Use CMM to measure cookware thickness and size—adjust machining parameters if deviation >±0.03mm.

Polish Cavity Surface: Re-polish to Ra 0.2μm if roughness exceeds 0.3μm (use our recommended polishing kit).

Test Food-Grade Compliance: Swab the cavity and test for residue (using FDA-approved kits)—ensure no contamination.

Warranty Coverage:

2.5-year warranty for the mold body (covers warping/cracks); 1-year warranty for cavity coating and guide pins.

For food-grade critical molds, extend coating warranty to 1.5 years (50% extra cost)— a U.S. brand used this to meet Walmart’s 2-year supplier guarantee.

24/7 Technical Support:

Our team of 4 cookware mold engineers (10+ years experience) offers round-the-clock help via phone/WhatsApp/video.

For urgent issues (e.g., mold failure during a holiday order rush), respond within 20 minutes—85% resolved remotely in 1 hour.

Spare Parts & Finishing Kits:

Stock guide pins, food-grade polishing compounds, and cooling O-rings in 3 regional warehouses (China, Germany, U.S.).

24-hour delivery— a Brazilian factory received replacement guide pins in 16 hours, minimizing downtime to 1 shift.

On-Site Training:

Free 2-day training for your team—covers mold setup, food-grade release agent use, and cavity maintenance.

A Chinese cookware brand’s team reduced mold-related defects from 9% to 1.2% after training, mastering “polishing techniques for non-stick pans.”

Specialization in Cookware Molds: We don’t make generic molds—we focus exclusively on aluminum cookware, understanding unique needs (even heating, food safety, non-stick compatibility). Our R&D team tests every mold with real cookware production (induction testing, coating adhesion) to solve actual pain points.

Proven B2B Track Record: Over 200 cookware manufacturers in 40 countries use our molds, including suppliers to Walmart, Lidl, and T-fal. A Chinese brand increased annual revenue by $3M after using our molds to meet FDA standards, entering the U.S. market.

Transparent ROI for Cookware Production: We provide a customized ROI calculator (based on your rejection rates, labor costs, and mold lifespan). Most clients recoup investment in 12-16 months—for a factory with 2 4-cavity pan molds, this means $192,000 in 5-year savings (rework + labor + mold replacement).

Global Food Safety Expertise: We handle all regulatory paperwork (FDA/LFGB/EN 12983) and provide test reports for customer audits. A European brand used our documentation to pass Tesco’s supplier audit in 3 days, vs. 1 week with previous molds.

Flexible Lead Times for Urgent Orders: Standard molds (16-24cm pans) are in stock (delivery 7-10 days). Custom molds take 15-20 days—40% faster than competitors (30+ days). A Thai cookware factory received custom wok molds in 18 days, meeting a $500,000 rush order for Chinese New Year.

Q1: Will this mold work with our existing 400T Yizumi die casting machine and produce our 28cm A380 aluminum soup pot?

Q2: Can the mold be customized for our unique 32cm induction stockpot (curved sides, 4mm thickness)?

Q3: Does the mold ensure our cookware meets FDA standards, and do you provide test reports?

Q4: How often do we need to re-polish the cavity, and is it easy to do?

Custom die casting mould exclusively for aluminum alloy cookware: non-stick pans, soup pots, stockpots, and induction-compatible cookware, tailored to B2B cookware manufacturers’ size/shape needs.

Applicable to food-grade aluminum alloys (ADC12, A380) — ensures cookware meets FDA (U.S.) and LFGB (EU) food contact standards, with no heavy metal leaching.

Features 1-6 cavity configurations: 1-cavity for large stockpots (24-32cm diameter), 6-cavity for small pans (16-20cm diameter), matching low/high-volume production.

Achieves ±0.03mm dimensional accuracy (critical for cookware thickness uniformity: 2-5mm) and Ra 0.2μm cavity surface roughness (reduces post-polishing time by 60%).

Integrates cookware-specific designs: heat-conducting base optimization (3mm thick for even heating), non-stick coating pre-treatment grooves, and anti-deformation reinforcing ribs.

Complies with industrial standards (ISO 9001, CE) and supports global B2B export, compatible with 200T-800T cold-chamber die casting machines (LH, Yizumi, Haitian).

Visually, the mold has a robust, gray H13 steel frame—streamlined (600mm width for 4-cavity pan mold) to fit cookware production lines without blocking access. When you touch the cavity surface, it feels mirror-smooth (Ra 0.2μm) and cool to the touch (even after 100 cycles) thanks to the internal cooling channels, unlike traditional molds that leave cookware with rough, scratch-prone surfaces. The mold’s guide pins are polished to a chrome finish, sliding into bushings with a soft “click” — no grinding that damages cookware edges. There’s a faint, clean metallic scent (no chemical residues from low-quality lubricants), a sign of food-grade-compatible processing. During production, you’ll notice molten aluminum flows evenly into the cavity’s heat-conducting base (3mm thickness, ±0.02mm tolerance)—no air bubbles that cause hot spots. The demolding system uses gentle air pressure (0.3MPa) to release cookware without scratches; post-production, the pan’s surface is smooth enough for direct non-stick coating (no extra polishing). Every detail—from the food-grade mold release agent compatibility (avoids residue) to the etched size marks (16cm/18cm) — is designed to make aluminum cookware production reliable, compliant, and cost-effective for B2B manufacturers.

Ultra-Precision Ensures Even Cookware Heating (Cuts Rejects by 80%): The mold’s 5-axis CNC machining (tolerance ±0.005mm) and EDM wire cutting create cavities with ±0.03mm dimensional accuracy—ensuring cookware thickness uniformity (2-5mm, ±0.02mm). A European cookware brand reduced induction heating failure rates from 18% to 3.6%, saving $12,240/year in rework. The heat-conducting base design (3mm thick, no thin spots) eliminates hot spots—tests show temperature variation across pan surfaces drops from 25℃ to 5℃, meeting European EN 12983 cookware standards. For stockpots, the mold’s uniform wall thickness (4mm) ensures even boiling, reducing customer complaints by 70%.

Food-Grade Compliance Meets Global Standards: The mold’s cavity is polished to Ra 0.2μm and treated with a food-grade-compatible coating (no heavy metals) — ensuring cookware meets FDA 21 CFR 175.300 (U.S.) and LFGB §30 (EU) food contact requirements. A U.S. cookware manufacturer passed Walmart’s supplier audit with zero non-compliances, winning a \(2M annual order. The mold’s compatibility with food-grade aluminum alloys (ADC12, A380) and non-stick coating pre-treatment grooves (0.1mm depth) eliminates coating adhesion issues— a Chinese brand reduced non-stick peeling rates from 10% to 1.5%, avoiding \)8,500/month in returns.

Multi-Cavity Design Boosts Production Efficiency (Saves 40% Time): The 1-6 cavity configuration adapts to production volumes: 6-cavity for small pans (16-20cm) increases output by 500% vs. 1-cavity; 1-cavity for large stockpots (32cm) avoids overloading. A Brazilian cookware factory with 3 4-cavity molds increased daily pan production from 800 to 3,200, meeting a $1.5M order from a supermarket chain. The mold’s fast cycle time (40-60 seconds/cavity) — 20% faster than generic molds — adds 120 extra pans/day per machine. The self-lubricating guide pins (PTFE-lined) also cut maintenance time by 3 hours/week (no monthly oiling), reducing downtime by 15%.

Polished Cavities Reduce Post-Processing (Cuts Labor by 60%): The cavity’s Ra 0.2μm surface roughness (achieved via 3-stage polishing) eliminates 60% of manual polishing work— a U.S. factory reduced polishing labor from 4 hours to 1.6 hours per batch, saving \(5,400/month. For non-stick cookware, the smooth surface ensures uniform coating application (thickness variation ±5%)— reducing coating material use by 20% (from 50ml to 40ml per pan). The mold’s demolding air pressure system (0.3MPa) also prevents scratches— cookware surface defect rates drop from 8% to 1%, cutting rework costs by \)6,000/year.

Durable Design Extends Mold Lifespan (300,000+ Cycles): The mold’s H13 die steel (52-54 HRC hardness) resists wear from aluminum oxide— ensuring consistent precision for 300,000+ cycles (vs. 150,000 cycles for low-grade steel). A Thai cookware factory used 2 molds for 3 years with zero cavity replacement, saving $30,000 in mold costs. The internal cooling channels (5mm from cavity surface) reduce thermal stress— mold warpage rates drop by 80%, maintaining dimensional accuracy over time. For high-volume production (10,000+ pieces/month), the mold’s corrosion-resistant vent holes (prevents aluminum buildup) ensure 24/7 operation without clogging.

| Parameter Name | Specification |

| Mold Type | Custom Die Casting Mould for Aluminum Alloy Cookware/Pots |

| Applicable Cookware | Pans (16-24cm), Soup Pots (20-28cm), Stockpots (24-32cm) |

| Compatible Materials | Food-Grade Aluminum Alloys (ADC12, A380) |

| Dimensional Accuracy | ±0.03mm (Cavity); ±0.02mm (Heat-Conducting Base) |

| Surface Roughness (Cavity) | Ra 0.2μm |

| Mold Lifespan | 300,000+ Cycles (ADC12); 350,000+ Cycles (A380) |

| Cavity Quantity | 1/2/4/6 Cavities (Customizable) |

| Applicable Die Casting Machines | 200T-800T Cold-Chamber (LH, Yizumi, Haitian, Toshiba) |

| Mold Material | H13 Hot-Work Die Steel (52-54 HRC Hardness) |

| Cavity Treatment | Food-Grade Polishing + Anti-Corrosion Coating |

| Cooling System | Internal Water Channels (5mm from Cavity Surface) |

| Demolding Method | Air Pressure (0.2-0.4MPa) + Ejector Pins |

| Cookware Thickness Range | 2-5mm (Adjustable) |

| Compliance Standards | FDA 21 CFR 175.300, LFGB §30, ISO 9001, CE, EN 12983 |

| Dimensions (L×W×H) | 1-Cavity (32cm Stockpot): 700×500×350mm; 6-Cavity (18cm Pan): 900×600×400mm |

| Net Weight | 1-Cavity: 150kg; 6-Cavity: 320kg |

| Warranty | 2.5 Years (Mold Body); 1 Year (Cavity Coating/Guide Pins) |

| Additional Features | Non-Stick Coating Grooves, Size Markings, Food-Grade Release Agent Compatibility |

Non-Stick Pans (16-24cm, ADC12 Aluminum): Ideal for 4-6 cavity molds—producing pans with Ra 0.2μm surfaces (direct non-stick coating). A Chinese cookware brand used 3 6-cavity molds to produce 1.2 million pans/year—polishing labor cut by 60%, and non-stick adhesion rates improved to 98.5%, winning a contract with Lidl.

Induction Soup Pots (20-28cm, A380 Aluminum): Perfect for 2-cavity molds— the heat-conducting base (3mm thickness, ±0.02mm) ensures induction compatibility. A European brand reduced induction failure rates from 15% to 2%, meeting EN 12983 standards and increasing sales by 35%.

Large Stockpots (24-32cm, ADC12 Aluminum): Suitable for 1-cavity molds— uniform wall thickness (4mm) prevents warping during boiling. A U.S. restaurant supply company produced 50,000 stockpots/year— customer complaints about uneven heating dropped from 20% to 3%, saving $12,000/year in returns.

Custom Specialty Cookware (e.g., Woks, Grill Pans): The mold’s customization flexibility supports unique shapes— a Korean brand ordered custom wok molds (36cm diameter, curved sides) — delivered in 18 days, enabling a new product launch that captured 15% of the local wok market.

Cookware Design Consultation (3-4 Days):

Our engineers review your cookware 3D models (STEP/IGES) and requirements: size (16-32cm), type (pan/pot), target market (FDA/LFGB), and production volume.

We recommend optimizations: e.g., 3mm heat-conducting base for induction pans, 0.1mm grooves for non-stick coating.

Example: For a 28cm soup pot targeting EU markets, we added LFGB-compliant cavity treatment and reinforced base ribs.

Cavity Design & Simulation (7-9 Days):

Create 3D mold models with cookware-specific features: heat-conducting bases, size markings, demolding guides.

Run flow simulation (Moltenflow) to test aluminum filling (avoids air bubbles) and thermal simulation (ensures even cooling).

Share designs with your team for feedback—95% approve after 1-2 iterations.

Material Selection & Preprocessing (5-6 Days):

Source H13 steel from certified mills (with MTRs) and cut to mold blank size via CNC sawing.

Apply initial heat treatment (annealing) to reduce stress—prevents mold warping during machining.

For food-grade compliance, pre-polish cavity surfaces to Ra 0.5μm (base for final finishing).

Precision Machining & Finishing (10-12 Days):

Use 5-axis CNC machining to shape cavities (tolerance ±0.005mm) and EDM wire cutting for fine features (e.g., coating grooves).

Polish cavities to Ra 0.2μm (3-stage process: grinding→lapping→buffing) and apply food-grade anti-corrosion coating.

Assemble components (guide pins, cooling fittings) and test mold opening/closing (ensures smooth operation).

Test Run & Validation (3-4 Days):

Conduct test runs on our 400T die casting machine (using your aluminum alloy) to produce 50 sample cookware pieces.

Inspect samples via CMM (dimensional accuracy) and food-grade testing (residue analysis)—share reports with your quality team.

Adjust parameters (cooling time, demolding pressure) until samples meet your standards.

Delivery & Training (2-3 Days):

Deliver the mold with a kit (spare guide pins, polishing tools) and provide on-site installation guidance.

Train your team on mold maintenance (food-grade release agent use, cavity cleaning) and troubleshooting (e.g., dealing with aluminum buildup).

Material & Surface Quality Checks:

H13 steel is inspected via ultrasonic testing (UT) to detect internal cracks—rejecting defective blanks.

Cavity surfaces are tested for roughness (Ra 0.2μm) and food-grade compliance (ICP-MS for heavy metals: Pb/Cd <1ppm).

Precision & Performance Testing:

Use a Zeiss CMM (accuracy ±0.001mm) to measure cookware thickness, size, and heat-conducting base uniformity.

Conduct 100-cycle test runs—mold must maintain ±0.03mm accuracy and produce cookware with ≤5℃ temperature variation.

Global Compliance Certification:

Full compliance with ISO 9001, CE, FDA 21 CFR 175.300, and LFGB §30.

Provide documentation: material MTRs, food-grade test reports, and EN 12983 cookware performance certificates.

Post-Delivery Validation:

We provide 1 week of on-site support—adjusting mold parameters to ensure 99%+ qualified cookware.

For large orders (100,000+ pieces/year), assign a dedicated engineer to monitor mold performance monthly.

Pre-Operation Checks (5 Minutes/Day):

Inspect Cavity Surface: Check for scratches (use food-grade polishing compound to repair minor defects) and residue (wipe with food-grade solvent).

Test Cooling Water Flow: Verify 100-150L/h flow rate (depends on mold size)—low flow causes cookware warping. Clean filters if pressure <0.3MPa.

Verify Demolding Pressure: Set to 0.2-0.4MPa (lower for small pans, higher for stockpots)—too much pressure causes scratches.

Check Release Agent Compatibility: Use only food-grade release agents (we provide a recommended list)—avoid harsh chemicals that damage the cavity coating.

Weekly Maintenance (1.5 Hours):

Deep-Clean Cavities: Use a soft brass brush to remove aluminum residue—avoid steel brushes that scratch Ra 0.2μm surfaces.

Lubricate Guide Pins: Apply food-grade grease (provided) to 4 guide pins—prevents wear and ensures smooth movement.

Inspect Cooling Channels: Flush with distilled water to remove mineral buildup—improves heat transfer and reduces cycle time.

Monthly Maintenance (3 Hours):

Calibrate Cavity Dimensions: Use CMM to measure cookware thickness and size—adjust machining parameters if deviation >±0.03mm.

Polish Cavity Surface: Re-polish to Ra 0.2μm if roughness exceeds 0.3μm (use our recommended polishing kit).

Test Food-Grade Compliance: Swab the cavity and test for residue (using FDA-approved kits)—ensure no contamination.

Warranty Coverage:

2.5-year warranty for the mold body (covers warping/cracks); 1-year warranty for cavity coating and guide pins.

For food-grade critical molds, extend coating warranty to 1.5 years (50% extra cost)— a U.S. brand used this to meet Walmart’s 2-year supplier guarantee.

24/7 Technical Support:

Our team of 4 cookware mold engineers (10+ years experience) offers round-the-clock help via phone/WhatsApp/video.

For urgent issues (e.g., mold failure during a holiday order rush), respond within 20 minutes—85% resolved remotely in 1 hour.

Spare Parts & Finishing Kits:

Stock guide pins, food-grade polishing compounds, and cooling O-rings in 3 regional warehouses (China, Germany, U.S.).

24-hour delivery— a Brazilian factory received replacement guide pins in 16 hours, minimizing downtime to 1 shift.

On-Site Training:

Free 2-day training for your team—covers mold setup, food-grade release agent use, and cavity maintenance.

A Chinese cookware brand’s team reduced mold-related defects from 9% to 1.2% after training, mastering “polishing techniques for non-stick pans.”

Specialization in Cookware Molds: We don’t make generic molds—we focus exclusively on aluminum cookware, understanding unique needs (even heating, food safety, non-stick compatibility). Our R&D team tests every mold with real cookware production (induction testing, coating adhesion) to solve actual pain points.

Proven B2B Track Record: Over 200 cookware manufacturers in 40 countries use our molds, including suppliers to Walmart, Lidl, and T-fal. A Chinese brand increased annual revenue by $3M after using our molds to meet FDA standards, entering the U.S. market.

Transparent ROI for Cookware Production: We provide a customized ROI calculator (based on your rejection rates, labor costs, and mold lifespan). Most clients recoup investment in 12-16 months—for a factory with 2 4-cavity pan molds, this means $192,000 in 5-year savings (rework + labor + mold replacement).

Global Food Safety Expertise: We handle all regulatory paperwork (FDA/LFGB/EN 12983) and provide test reports for customer audits. A European brand used our documentation to pass Tesco’s supplier audit in 3 days, vs. 1 week with previous molds.

Flexible Lead Times for Urgent Orders: Standard molds (16-24cm pans) are in stock (delivery 7-10 days). Custom molds take 15-20 days—40% faster than competitors (30+ days). A Thai cookware factory received custom wok molds in 18 days, meeting a $500,000 rush order for Chinese New Year.

Q1: Will this mold work with our existing 400T Yizumi die casting machine and produce our 28cm A380 aluminum soup pot?

Q2: Can the mold be customized for our unique 32cm induction stockpot (curved sides, 4mm thickness)?

Q3: Does the mold ensure our cookware meets FDA standards, and do you provide test reports?

Q4: How often do we need to re-polish the cavity, and is it easy to do?