EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-RADIATOR

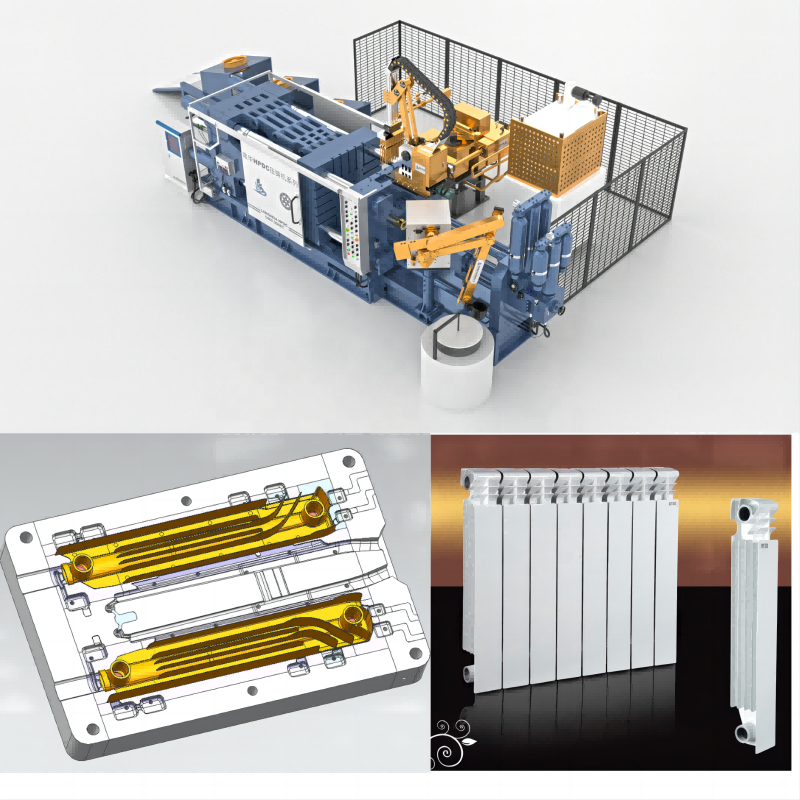

Our Customized Production Line is designed to deliver high-precision, high-airtightness aluminum die-casting radiators, optimized for performance and durability. The process is tailored to meet your specific requirements, ensuring that each radiator is crafted with precision and high quality. Below, we outline the major steps involved in the production process:

The production process begins with the careful selection and preparation of raw materials. We use high-quality cast iron or aluminum alloys, each rigorously tested for compliance with product standards. This step ensures that only the best materials are used in the manufacturing process, resulting in reliable and long-lasting radiators.

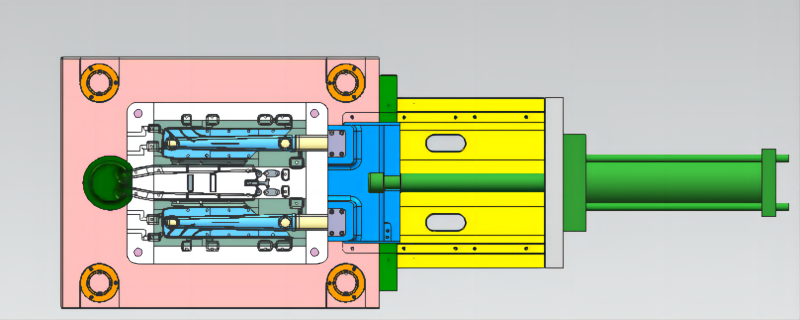

The aluminum die-casting process is the core of radiator production. In this step, the prepared aluminum alloy is heated and forced into precisely crafted molds under high pressure. The molds are designed based on your specifications and can be made of metal or other suitable materials to ensure accuracy and consistency. The result is a perfectly shaped radiator, ready for further processing.

After the radiator takes its basic form, we perform critical finishing operations including cutting, grinding, and shaping to achieve the desired surface quality and dimensional accuracy. This step ensures that the radiators meet your performance requirements, with a smooth and flawless finish. Additional processes such as heat treatment and packaging are also completed to ensure optimal performance and secure delivery.

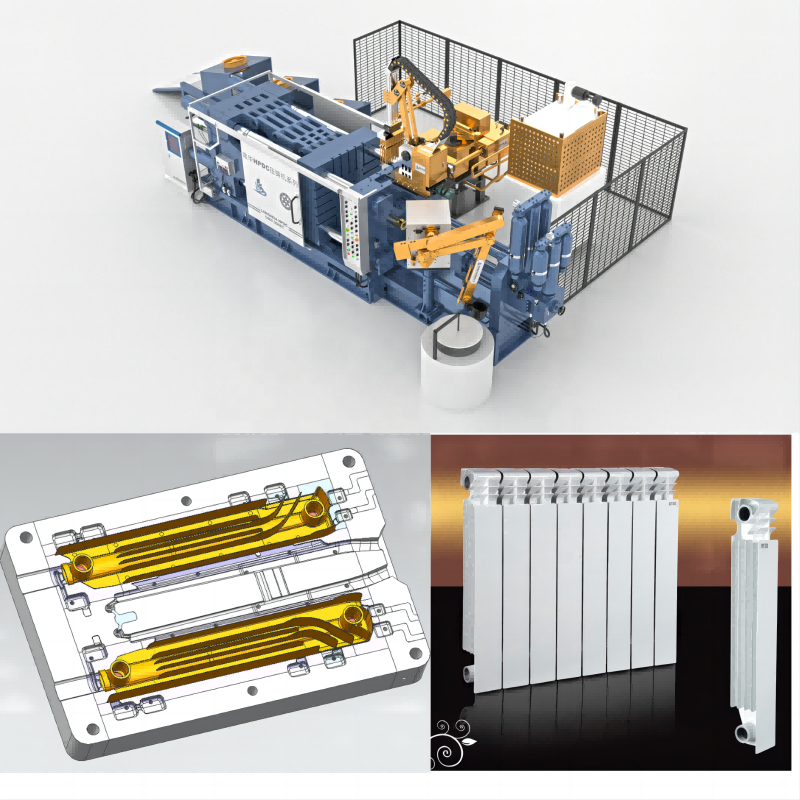

Our Customized Production Line is designed to deliver high-precision, high-airtightness aluminum die-casting radiators, optimized for performance and durability. The process is tailored to meet your specific requirements, ensuring that each radiator is crafted with precision and high quality. Below, we outline the major steps involved in the production process:

The production process begins with the careful selection and preparation of raw materials. We use high-quality cast iron or aluminum alloys, each rigorously tested for compliance with product standards. This step ensures that only the best materials are used in the manufacturing process, resulting in reliable and long-lasting radiators.

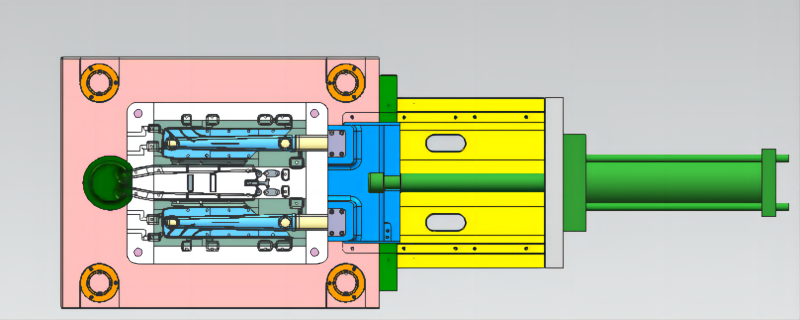

The aluminum die-casting process is the core of radiator production. In this step, the prepared aluminum alloy is heated and forced into precisely crafted molds under high pressure. The molds are designed based on your specifications and can be made of metal or other suitable materials to ensure accuracy and consistency. The result is a perfectly shaped radiator, ready for further processing.

After the radiator takes its basic form, we perform critical finishing operations including cutting, grinding, and shaping to achieve the desired surface quality and dimensional accuracy. This step ensures that the radiators meet your performance requirements, with a smooth and flawless finish. Additional processes such as heat treatment and packaging are also completed to ensure optimal performance and secure delivery.