EMAIL:

sales@longhuamachine.com

TELL/whatsapp:

+86-18905522221  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-MOULD-LIGHT

Longhua

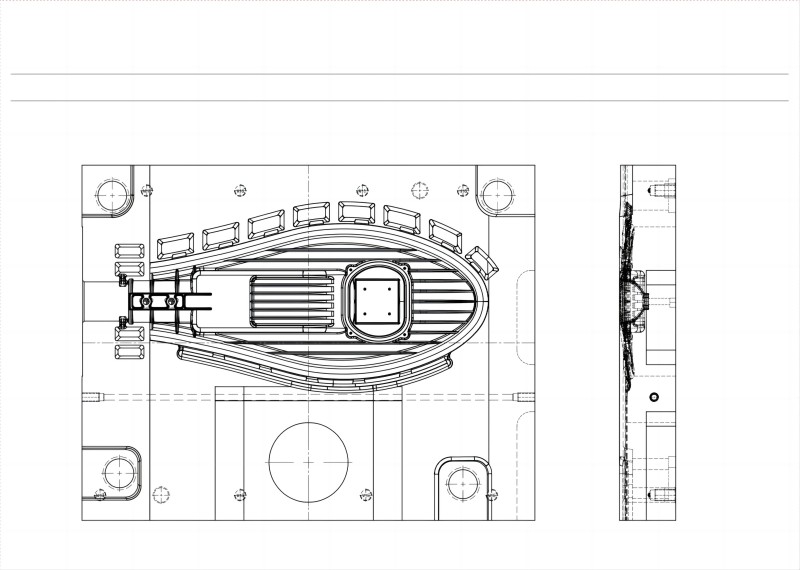

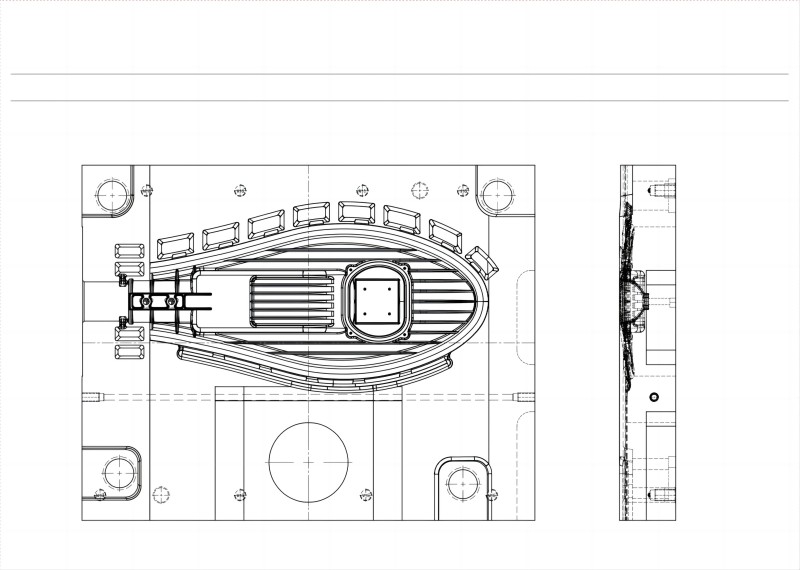

The Die-Casting Lamp Mold for Aluminum Alloy Street Lights by LongHua is designed for high-performance street lighting applications. Made from durable aluminum alloys like AL6061, AL6061-T6, AL6063, AL6063-T6, and AL7075, these moulds provide excellent strength and heat resistance for long-lasting use.

This die-casting mould comes with a weight range of 0.015 to 8 kg (0.033 to 18 lbs) and maintains tight tolerances ranging from 0.005 mm to 0.1 mm. The product undergoes a combination of casting, machining, and surface treatment to achieve optimal results.

Various surface treatments are available, including anodizing, sandblasting, powder coating, and electroplating (zinc, chrome, nickel, silver, gold). Additional finishes like polishing, nitriding, blackening, and painting are also offered to meet specific requirements.

| Parameter | Value |

| Brand | OEM |

| Model | OEM |

| Material | Aluminum (AL6061, AL6061-T6, AL6063, AL6063-T6, AL7075, AL7075-T) |

| Weight | 0.015-8 kg (0.033-18 lbs) |

| Tolerance | 0.005 mm to 0.1 mm |

| Processing Method | Casting + Machining (if required) + Surface Treatment |

| Surface Treatment | Anodizing, Sandblasting, Powder Coating, Electroplating (Zinc, Chrome, Nickel, Silver, Gold), Polishing, Nitriding, Blackening, Painting, Heat Treatment |

| Packaging | Polyethylene bag + Inner box + Carton |

| Product Dimensions | 12 x 10 x 15 cm (individual packaging) |

| Gross Weight | 3.5 kg (individual product) |

Customization: Customized molds are made according to the drawings provided by customers (size, material, processing details), and the tolerance surface roughness (Ra0.2-Ra3.2) and tolerance range (±0.05-0.1mm) can be customized.

Precision Casting: The aluminum gravity die-casting process ensures high accuracy and precision, suitable for applications requiring reliability and durability.

Durable Surface Treatment: The product is sandblasted and polished to provide a long-lasting wear-resistant surface, which is very suitable for use in harsh environments.

Long service life: The mold life is 50,000 to 80,000 times, ensuring long-term use with minimal maintenance.

Cost-effective production: The die-casting process reduces material waste and optimizes production efficiency, saving costs for mass production.

Reliable performance: The mold design meets high precision standards to ensure consistent and reliable results, which is ideal for large-scale street lamp production.

Durable design: The mold is suitable for outdoor applications and can withstand challenging conditions, providing long-term durability in street lighting.

Versatile application: Mainly used to manufacture aluminum alloy street lamps, but suitable for other outdoor lighting solutions that require precision and reliability.

Q1: What materials are used for die casting lamp molds?

A1: Our molds are made of high-quality aluminum alloy, ensuring durability and precision during production.

Q2: What is the service life of these die casting molds?

A2: The mold service life is between 50,000 and 80,000 cycles, providing long-term reliability for your production needs.

Q3: Can you customize the molds to our specifications?

A3: Yes, we offer full customization based on your drawings, including material, size and tolerance specifications.

Q4: What are the applications of these molds?

A4: These molds are mainly used to manufacture aluminum alloy street lights, but can also be suitable for other outdoor lighting products.

Q5: How long does it take to manufacture a mold?

A5: The lead time for mold production varies depending on the customization requirements, but it usually takes 4-6 weeks.

The Die-Casting Lamp Mold for Aluminum Alloy Street Lights by LongHua is designed for high-performance street lighting applications. Made from durable aluminum alloys like AL6061, AL6061-T6, AL6063, AL6063-T6, and AL7075, these moulds provide excellent strength and heat resistance for long-lasting use.

This die-casting mould comes with a weight range of 0.015 to 8 kg (0.033 to 18 lbs) and maintains tight tolerances ranging from 0.005 mm to 0.1 mm. The product undergoes a combination of casting, machining, and surface treatment to achieve optimal results.

Various surface treatments are available, including anodizing, sandblasting, powder coating, and electroplating (zinc, chrome, nickel, silver, gold). Additional finishes like polishing, nitriding, blackening, and painting are also offered to meet specific requirements.

| Parameter | Value |

| Brand | OEM |

| Model | OEM |

| Material | Aluminum (AL6061, AL6061-T6, AL6063, AL6063-T6, AL7075, AL7075-T) |

| Weight | 0.015-8 kg (0.033-18 lbs) |

| Tolerance | 0.005 mm to 0.1 mm |

| Processing Method | Casting + Machining (if required) + Surface Treatment |

| Surface Treatment | Anodizing, Sandblasting, Powder Coating, Electroplating (Zinc, Chrome, Nickel, Silver, Gold), Polishing, Nitriding, Blackening, Painting, Heat Treatment |

| Packaging | Polyethylene bag + Inner box + Carton |

| Product Dimensions | 12 x 10 x 15 cm (individual packaging) |

| Gross Weight | 3.5 kg (individual product) |

Customization: Customized molds are made according to the drawings provided by customers (size, material, processing details), and the tolerance surface roughness (Ra0.2-Ra3.2) and tolerance range (±0.05-0.1mm) can be customized.

Precision Casting: The aluminum gravity die-casting process ensures high accuracy and precision, suitable for applications requiring reliability and durability.

Durable Surface Treatment: The product is sandblasted and polished to provide a long-lasting wear-resistant surface, which is very suitable for use in harsh environments.

Long service life: The mold life is 50,000 to 80,000 times, ensuring long-term use with minimal maintenance.

Cost-effective production: The die-casting process reduces material waste and optimizes production efficiency, saving costs for mass production.

Reliable performance: The mold design meets high precision standards to ensure consistent and reliable results, which is ideal for large-scale street lamp production.

Durable design: The mold is suitable for outdoor applications and can withstand challenging conditions, providing long-term durability in street lighting.

Versatile application: Mainly used to manufacture aluminum alloy street lamps, but suitable for other outdoor lighting solutions that require precision and reliability.

Q1: What materials are used for die casting lamp molds?

A1: Our molds are made of high-quality aluminum alloy, ensuring durability and precision during production.

Q2: What is the service life of these die casting molds?

A2: The mold service life is between 50,000 and 80,000 cycles, providing long-term reliability for your production needs.

Q3: Can you customize the molds to our specifications?

A3: Yes, we offer full customization based on your drawings, including material, size and tolerance specifications.

Q4: What are the applications of these molds?

A4: These molds are mainly used to manufacture aluminum alloy street lights, but can also be suitable for other outdoor lighting products.

Q5: How long does it take to manufacture a mold?

A5: The lead time for mold production varies depending on the customization requirements, but it usually takes 4-6 weeks.