EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

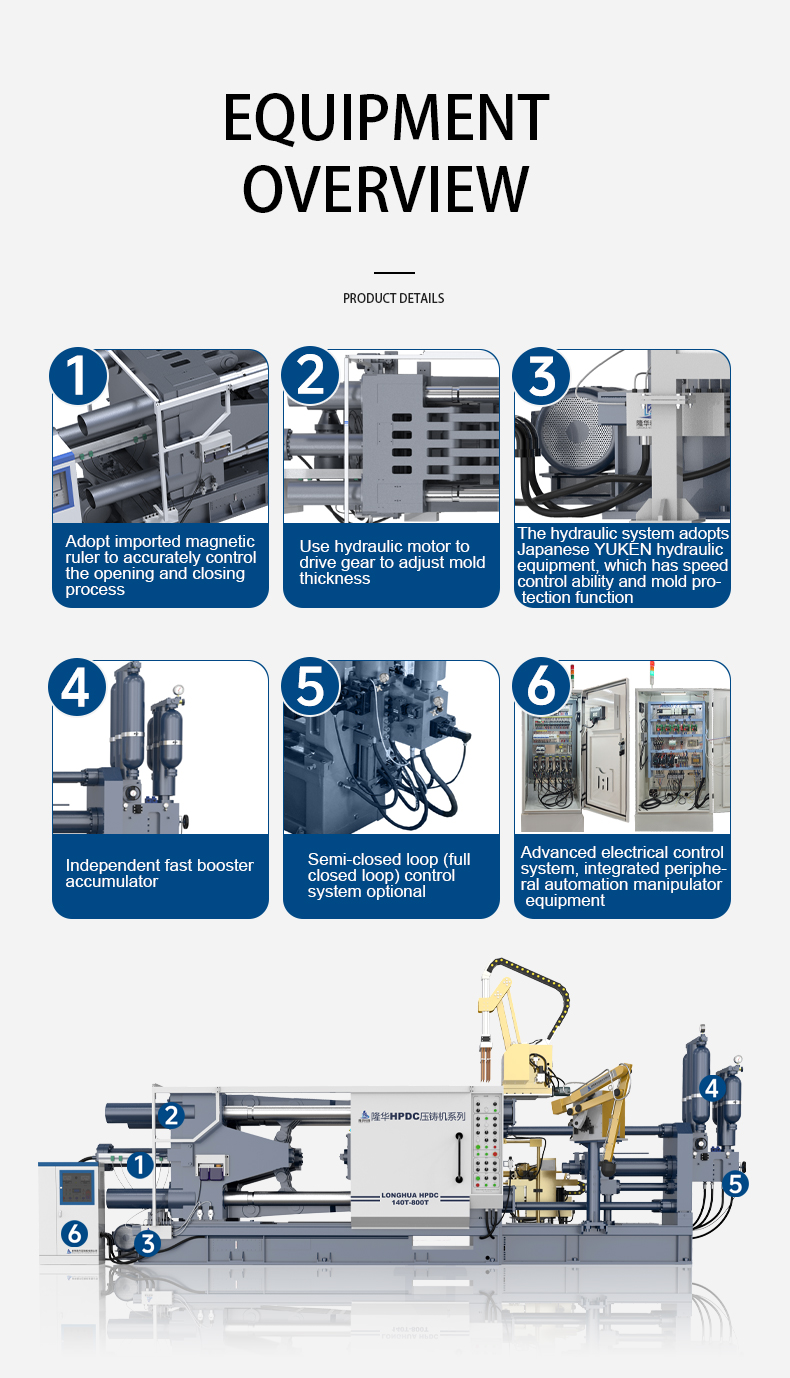

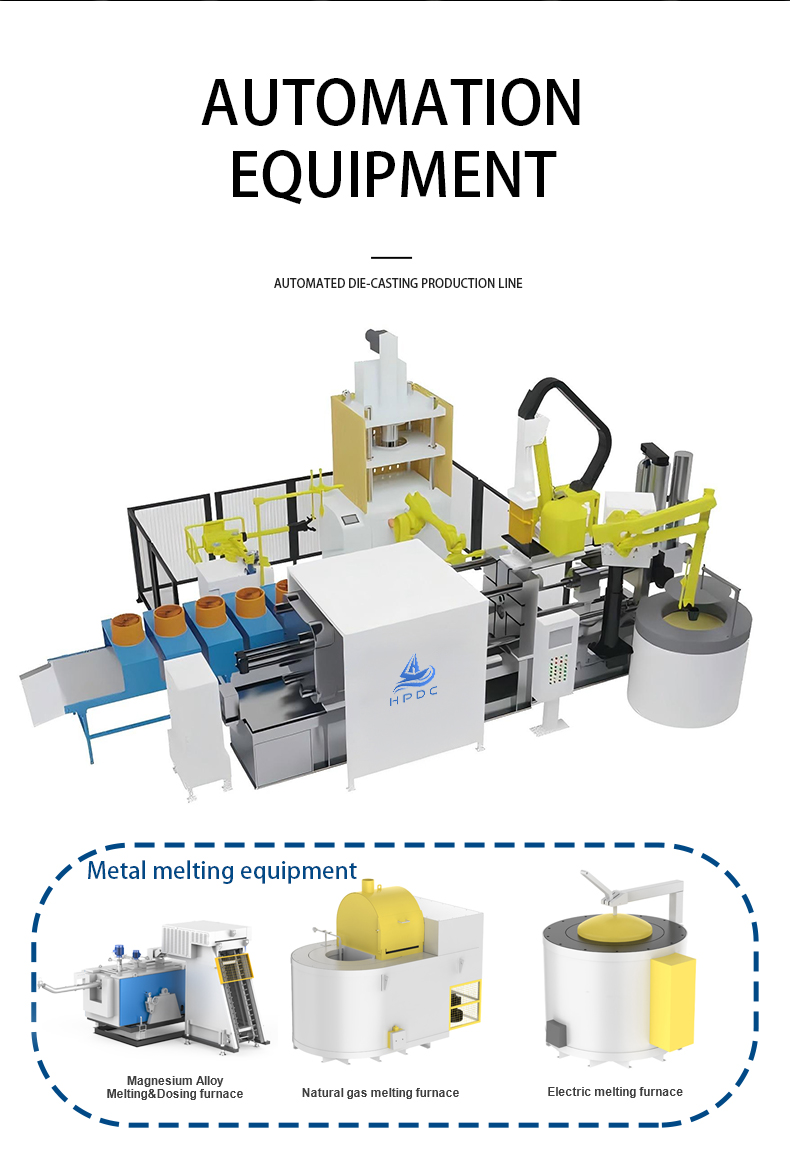

The aluminum-zinc alloy door handle die casting machine is designed to meet the demanding needs of various industries. It produces high-quality, precision parts with a focus on efficiency and consistency. The machine is designed to handle materials such as aluminum, zinc alloy, stainless steel, steel, and iron.

The machine uses a variety of casting methods, including die casting, investment casting, sand casting, and gravity casting. It provides 0.01 mm accuracy, ensuring accuracy in every production run. The machine is ISO9001:2015 certified, guaranteeing high quality standards.

| Parameter | Value |

| Materials | Aluminum Alloy, Zinc Alloy, Stainless Steel, Steel, Iron |

| Casting Process | Die Casting, Investment Casting, Sand Casting, Gravity Casting |

| Tolerance | 0.01mm |

| Certification | ISO9001:2015 |

| Applications | Automotive, Machinery, Electronics, Medical Devices |

| Surface Treatment | Spray Painting, Powder Coating, Nickel Plating, Electrophoresis |

| Services | One-stop OEM/ODM Service |

| Drawing Formats | 2D (DWG/DXF/PDF), 3D (STP/STEP/IGS) |

Customized Solutions: Provide tailor-made solutions for various industries. Work closely with customers to ensure precise fit, whether it is medical equipment or specialized parts.

High-quality materials and workmanship: Use high-quality aluminum and zinc alloys, processed with precision metal die-casting molds, with excellent precision and durability.

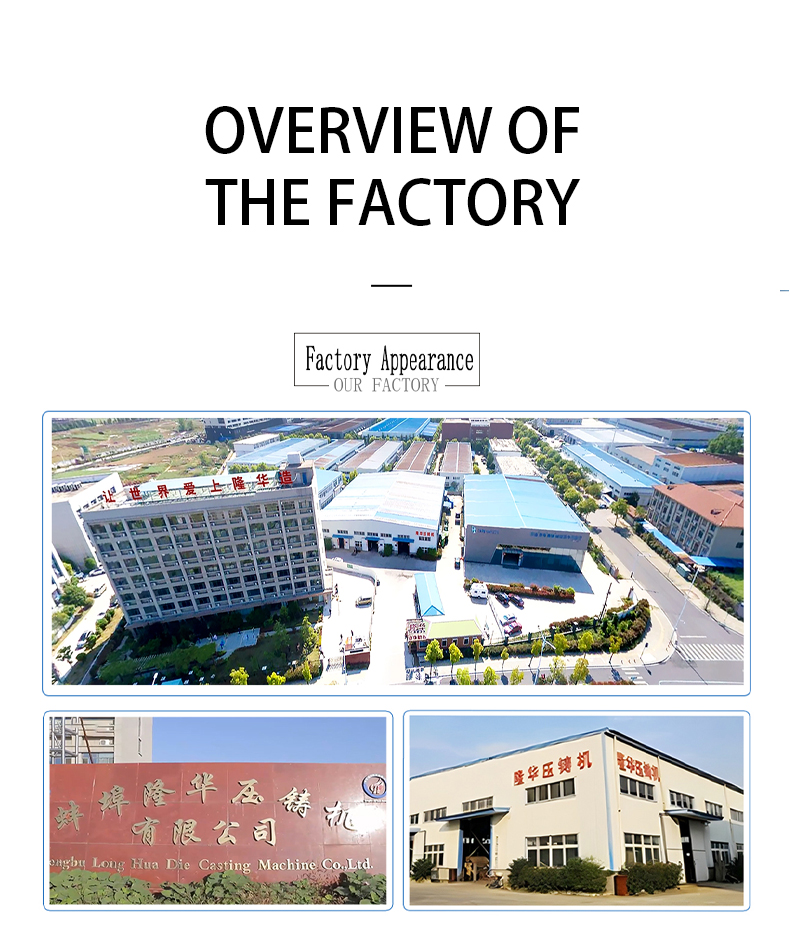

Strict quality control: The factory is ISO 9001:2008 certified, ensuring that the products meet the highest quality standards and reliability.

Precise tolerances: The tolerance of die castings is 0.01 mm, ensuring precise fit and reducing the risk of defects.

Custom size options: Flexible size options are provided to meet customer requirements, whether it is small-scale or large-scale production.

R&D Team: The R&D center consists of 2 industrial designers, 4 structural designers, 2 electronic engineers, 18 professional mold designers and 8 CNC programmers, ensuring expertise in all aspects of product development.

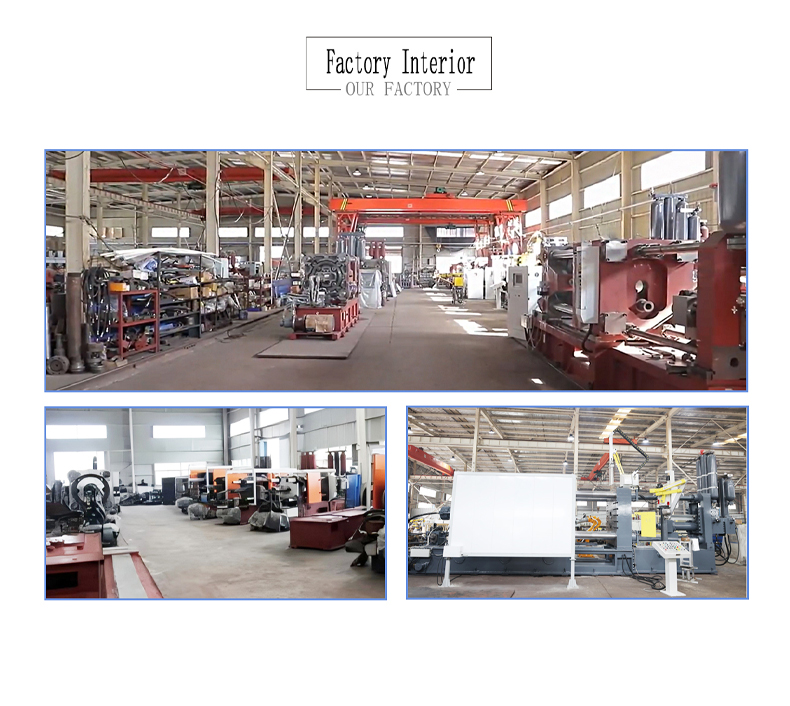

Precision mold manufacturing: Equipped with 8 high-precision CNC machines, 8 EDM machines, 2 WEDM (SODICK) machines, 1 mirror EDM and 15 coordinate milling machines, ensuring the production of high-quality molds for precise door handle components.

Advanced plastic product processing: 30 precision injection molding machines with clamping forces ranging from 80 tons to 1080 tons are capable of producing high-precision plastic parts with tight tolerances.

State-of-the-art measuring equipment: Utilize advanced measuring instruments such as BRUKER spectrometers, 2D measuring projectors, CMMs, surface roughness testers and intelligent hardness testers for precise quality control.

Automobile: Ideal for producing parts used in car doors and interior handles.

Mechanical: Can be used to produce precision parts in industrial machinery that require high strength and durability.

Electronic: Suitable for producing parts for electronic devices with complex designs and precision requirements.

Medical Devices: Ideal for manufacturing durable and high-precision parts for medical devices.

Q1: What materials can the die casting machine process?

A1: The machine processes aluminum alloy, zinc alloy, stainless steel, steel and iron.

Q2: What is the precision tolerance of the die casting?

A2: The machine offers a precision tolerance of 0.01mm.

Q3: Is the machine certified for quality standards?

A3: Yes, it is ISO 9001:2015 certified for high-quality production.

Q4: Can the machine be used for both small and large-scale production?

A4: Yes, it supports both small and large-scale production and offers customizable solutions.

Q5: What surface treatments can be applied to die castings?

A5: The machine offers painting, powder coating, nickel plating and electrophoresis.

The aluminum-zinc alloy door handle die casting machine is designed to meet the demanding needs of various industries. It produces high-quality, precision parts with a focus on efficiency and consistency. The machine is designed to handle materials such as aluminum, zinc alloy, stainless steel, steel, and iron.

The machine uses a variety of casting methods, including die casting, investment casting, sand casting, and gravity casting. It provides 0.01 mm accuracy, ensuring accuracy in every production run. The machine is ISO9001:2015 certified, guaranteeing high quality standards.

| Parameter | Value |

| Materials | Aluminum Alloy, Zinc Alloy, Stainless Steel, Steel, Iron |

| Casting Process | Die Casting, Investment Casting, Sand Casting, Gravity Casting |

| Tolerance | 0.01mm |

| Certification | ISO9001:2015 |

| Applications | Automotive, Machinery, Electronics, Medical Devices |

| Surface Treatment | Spray Painting, Powder Coating, Nickel Plating, Electrophoresis |

| Services | One-stop OEM/ODM Service |

| Drawing Formats | 2D (DWG/DXF/PDF), 3D (STP/STEP/IGS) |

Customized Solutions: Provide tailor-made solutions for various industries. Work closely with customers to ensure precise fit, whether it is medical equipment or specialized parts.

High-quality materials and workmanship: Use high-quality aluminum and zinc alloys, processed with precision metal die-casting molds, with excellent precision and durability.

Strict quality control: The factory is ISO 9001:2008 certified, ensuring that the products meet the highest quality standards and reliability.

Precise tolerances: The tolerance of die castings is 0.01 mm, ensuring precise fit and reducing the risk of defects.

Custom size options: Flexible size options are provided to meet customer requirements, whether it is small-scale or large-scale production.

R&D Team: The R&D center consists of 2 industrial designers, 4 structural designers, 2 electronic engineers, 18 professional mold designers and 8 CNC programmers, ensuring expertise in all aspects of product development.

Precision mold manufacturing: Equipped with 8 high-precision CNC machines, 8 EDM machines, 2 WEDM (SODICK) machines, 1 mirror EDM and 15 coordinate milling machines, ensuring the production of high-quality molds for precise door handle components.

Advanced plastic product processing: 30 precision injection molding machines with clamping forces ranging from 80 tons to 1080 tons are capable of producing high-precision plastic parts with tight tolerances.

State-of-the-art measuring equipment: Utilize advanced measuring instruments such as BRUKER spectrometers, 2D measuring projectors, CMMs, surface roughness testers and intelligent hardness testers for precise quality control.

Automobile: Ideal for producing parts used in car doors and interior handles.

Mechanical: Can be used to produce precision parts in industrial machinery that require high strength and durability.

Electronic: Suitable for producing parts for electronic devices with complex designs and precision requirements.

Medical Devices: Ideal for manufacturing durable and high-precision parts for medical devices.

Q1: What materials can the die casting machine process?

A1: The machine processes aluminum alloy, zinc alloy, stainless steel, steel and iron.

Q2: What is the precision tolerance of the die casting?

A2: The machine offers a precision tolerance of 0.01mm.

Q3: Is the machine certified for quality standards?

A3: Yes, it is ISO 9001:2015 certified for high-quality production.

Q4: Can the machine be used for both small and large-scale production?

A4: Yes, it supports both small and large-scale production and offers customizable solutions.

Q5: What surface treatments can be applied to die castings?

A5: The machine offers painting, powder coating, nickel plating and electrophoresis.