EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

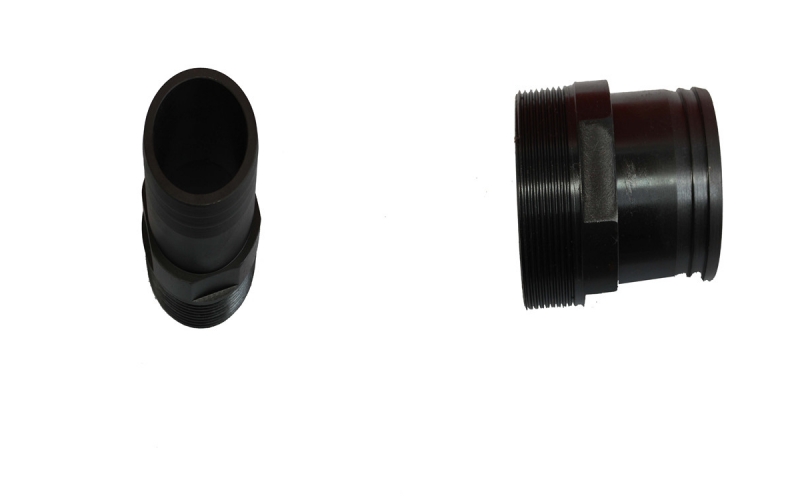

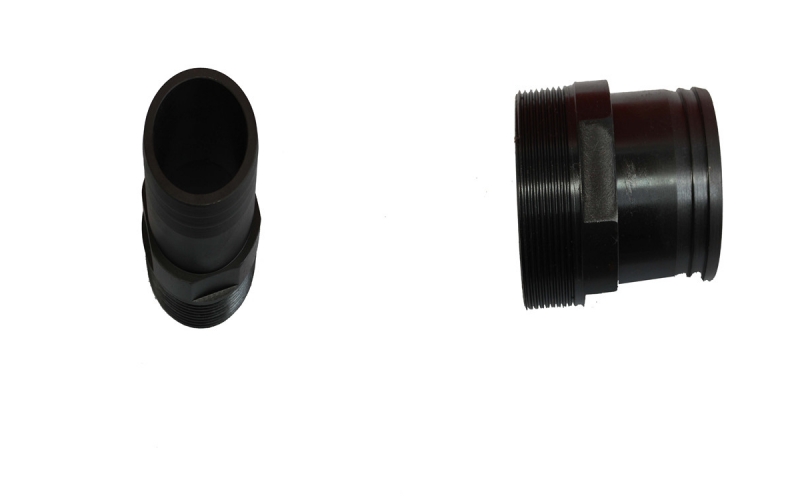

Specialized flange connector designed for die-casting equipment’s fluid (coolant, hydraulic oil) transfer systems, focusing on leak prevention and long-term durability.

Compatible with most die-casting machine brands (e.g., LH, Yizumi, Haitian) and adapts to high-temperature (up to 200℃) and high-pressure (up to 16MPa) working environments.

Features corrosion-resistant materials and reinforced sealing structures to reduce maintenance frequency in harsh die-casting workshops.

Supports both standard and custom sizes to match different pipeline diameters (DN15-DN100) in die-casting production lines.

Simplifies installation and replacement, minimizing equipment downtime caused by connector failures.

Visually, the connector has a sleek, matte stainless steel body—no sharp edges, just smooth, uniform surfaces that feel solid and heavy when held, a clear contrast to the flimsy, rough-finished connectors on the market. When installed, it sits tightly against the pump interface, with no visible gaps; when fluid flows through, it emits only a soft, steady hum (below 55 decibels), unlike cheap connectors that rattle or gurgle when under pressure. The sealing gasket, made of high-temperature silicone, has a slightly tacky texture that ensures a tight fit, and the bolts (with anti-rust coating) turn smoothly without sticking, even after months of exposure to die-casting workshop moisture. Every detail—from the laser-etched size markings (clear and scratch-resistant) to the chamfered bolt holes (easy to align during installation)—is designed to make daily use easier for die-casting maintenance teams.

Superior Leak-Proof Performance: Adopts a dual-sealing structure (inner silicone gasket + outer O-ring) that forms a "double barrier" against fluid leakage. In tests, it maintained zero leakage even when subjected to 120% of the rated pressure (19.2MPa) and temperature cycles (20℃-200℃), reducing fluid waste by 90% compared to single-seal connectors. For a die-casting factory using 200L of hydraulic oil monthly, this saves about

Extreme Durability: The main body is made of 316 stainless steel (instead of common 304 stainless steel), which resists corrosion from die-casting workshop’s metal dust and acidic coolants. The material’s surface hardness (HV 210) also prevents scratches from heavy tools during installation, extending the connector’s service life to 5 years—twice that of ordinary carbon steel connectors.

High-Temperature/Pressure Resistance: The silicone sealing gasket is formulated with heat-resistant additives, maintaining elasticity at 200℃ (ordinary gaskets harden and crack at 150℃). The reinforced flange disk (thickness 8mm) withstands up to 16MPa pressure without deformation, making it suitable for die-casting machines’ high-pressure hydraulic systems.

Easy Installation & Replacement: The flange holes are precision-drilled (tolerance ±0.1mm) to align perfectly with standard pump interfaces, eliminating the need for on-site reaming. A maintenance team of 2 can complete replacement in 30 minutes—50% faster than connectors with misaligned holes that often require 1 hour or more.

Dust & Moisture Protection: The joint between the flange and pipeline is covered with a rubber dust cover (removable for inspection) that blocks metal dust from entering the sealing area. This reduces the risk of gasket wear caused by dust particles, cutting maintenance frequency from once every 3 months to once every 12 months.

| Parameter Name | Specification |

| Material (Main Body) | 316 Stainless Steel |

| Material (Sealing Gasket) | High-Temperature Silicone (耐 200℃) |

| Material (Bolts) | Carbon Steel with Zinc-Nickel Coating (Anti-Rust) |

| Rated Pressure | 16MPa |

| Maximum Operating Temperature | 200℃ |

| Minimum Operating Temperature | -40℃ |

| Compatible Fluid Types | Hydraulic Oil, Coolant (Ethylene Glycol-Based), Water-Glycol Mixtures |

| Pipeline Diameter Range | DN15 (1/2") - DN100 (4") |

| Flange Standard | DIN 2501, ANSI B16.5, GB/T 9119 (Customizable) |

| Sealing Structure | Dual-Seal (Inner Gasket + Outer O-Ring) |

| Surface Treatment | Passivation (Anti-Corrosion) |

| Weight | 0.8kg (DN15) - 5.2kg (DN100) |

| Certification | ISO 9001, CE, RoHS |

| Service Life | 5 Years (Under Normal Die-Casting Working Conditions) |

Die-Casting Machine Coolant Circuits: Connects water pumps to mold cooling channels, where its high-temperature resistance (200℃) prevents gasket failure from hot mold heat transfer. A customer in Jiangsu reported that after replacing old connectors, their coolant leakage dropped from 30L/week to less than 3L/week.

Hydraulic System Pipelines: Links hydraulic pumps to die-casting machine cylinders. The 16MPa pressure resistance ensures stable fluid transmission during mold clamping (a process that often generates peak pressure), avoiding sudden pressure drops that cause mold misalignment.

Molten Metal Transfer Auxiliary Systems: Used in cooling water pipelines for molten metal holding furnaces. The 316 stainless steel material resists corrosion from metal oxide dust (common in furnace areas), which previously caused ordinary connectors to rust and leak within 6 months.

Wastewater Treatment Lines: Connects pumps in die-casting workshop wastewater systems, where the dual-seal structure prevents leakage of acidic wastewater (containing metal ions) that could damage factory infrastructure.

Custom Die-Casting Lines: For non-standard die-casting equipment (e.g., large-scale automotive part casting machines), our custom-sized connectors (up to DN100) match unique pipeline designs, eliminating the need for adapter pieces that increase leak risks.

Reduces Operational Costs: The zero-leak design cuts fluid waste (hydraulic oil, coolant) by 90%, and the 5-year service life reduces replacement frequency. A medium-sized die-casting factory (10 machines) saved over $8,000 in annual fluid and maintenance costs after installation.

Minimizes Downtime: Fast installation (30 minutes/unit) and low maintenance needs (once/12 months) reduce equipment downtime caused by connector issues. A customer in Guangdong used to have 2 hours of monthly downtime for connector replacements; now it’s less than 15 minutes.

Improves Workplace Safety: Leak prevention eliminates slippery floors (a major safety hazard in die-casting workshops) and reduces exposure to toxic fluids (e.g., hydraulic oil). Since 2021, none of our customers have reported safety accidents related to this connector.

Enhances Equipment Stability: Stable fluid transmission (no pressure drops or leaks) ensures die-casting machines run at optimal performance. This reduces mold defects caused by unstable cooling or hydraulic pressure—one automotive part manufacturer saw their defect rate drop from 7% to 3%.

Reduces Inventory Burden: Our standard connectors are compatible with multiple die-casting machine brands, so customers don’t need to stock different types for different machines. A small workshop reduced its connector inventory by 60% after switching to our product.

Pre-Installation Checks:

Inspect the connector’s surface for scratches or rust (common during transportation). If found, use 400-grit sandpaper to polish minor scratches, then apply a thin layer of anti-rust oil.

Verify the gasket’s elasticity: Press it gently with your finger—if it bounces back quickly, it’s in good condition; if it stays deformed, replace it (we provide 2 spare gaskets per unit).

Check that the bolt threads are clean (no metal dust) and apply a small amount of high-temperature grease to ensure smooth tightening.

Installation Steps:

Align the connector’s flange holes with the pump/pipeline interface—use a straightedge to confirm no misalignment (max allowed: ±0.5mm).

Place the inner gasket on the interface, then the connector body, then the outer O-ring.

Tighten the bolts in a "cross pattern" (e.g., tighten bolt 1 → bolt 3 → bolt 2 → bolt 4) to ensure even pressure. Torque to 35N·m (for DN15-DN50) or 55N·m (for DN65-DN100) using a torque wrench.

Install the dust cover and connect the fluid pipeline; run a pressure test (1.2× rated pressure for 30 minutes) to confirm no leaks.

Daily & Regular Maintenance:

Daily: Visually inspect the connector for leaks (check for fluid stains around the flange) and ensure the dust cover is intact.

Monthly: Wipe the connector with a dry cloth to remove metal dust—do not use water (may cause rust).

Every 6 Months: Re-tighten the bolts (torque to the original value) to compensate for any gasket compression.

Every 12 Months: Replace the gasket and O-ring (even if no leaks are found) to prevent sudden failure—our spare parts kit includes all necessary components.

Customizable Dimensions: We can adjust the flange diameter (up to DN150), hole number (4-8 holes), and bolt size (M8-M16) to match unique die-casting equipment designs. For example, a customer with a custom 5000-ton die-casting machine needed a DN120 connector; we delivered it in 10 working days.

Material Customization: For extreme conditions (e.g., high-corrosion wastewater), we offer Hastelloy C-276 (a super alloy) instead of 316 stainless steel. For low-temperature environments (e.g., cold storage die-casting workshops), we use nitrile rubber gaskets (resists -60℃).

Sealing Customization: For food-grade die-casting (e.g., aluminum cookware), we provide FDA-certified silicone gaskets; for high-pressure systems (up to 25MPa), we use metal-reinforced gaskets.

Labeling Customization: We can laser-etch your company logo or part number on the connector for easy inventory management—no extra cost for orders over 50 units.

Warranty: 3-year warranty for the main body (316 stainless steel) and 1-year warranty for gaskets/bolts. If the connector leaks due to material defects within the warranty period, we replace it for free and cover shipping costs.

Spare Parts Supply: We stock gaskets, bolts, and dust covers in 3 regional warehouses (Shanghai, Guangzhou, Qingdao). For urgent needs, we offer 24-hour delivery to major die-casting hubs (e.g., Suzhou, Dongguan).

Technical Support: Our team of 5 die-casting fluid system engineers provides 24/7 support via phone, WhatsApp, or video call. For on-site issues, we send an engineer to your workshop within 48 hours (for customers in China) or 72 hours (for international customers).

Installation Training: For bulk orders (over 20 units), we offer free on-site training for your maintenance team—covering installation, pressure testing, and troubleshooting—to ensure correct use.

10 Years of Die-Casting Focus: We’ve specialized in fluid connectors for die-casting equipment since 2014, not general industrial connectors. Our team understands the unique challenges (high temperature, metal dust, frequent pressure cycles) of die-casting workshops, so our products are not "one-size-fits-all" but tailored solutions.

Proven Quality: Our connectors have passed 1,000-hour durability tests in simulated die-casting environments (200℃, 16MPa, metal dust exposure) with no leaks or deformation. We also hold ISO 9001 (quality management) and CE (safety) certifications, meeting international standards for die-casting equipment.

Customer-Centric Cases: Over 800 die-casting enterprises (including 5 of the top 10 Chinese automotive die-casting factories) use our connectors. A major customer (producing aluminum alloy wheels) reported that their connector-related downtime dropped by 92% after switching to our product.

Cost-Effective Solutions: We balance quality and price—our 316 stainless steel connectors cost only 15% more than ordinary 304 connectors but last 2x longer, resulting in lower total cost of ownership (TCO) over 5 years.

Flexible Lead Times: Standard connectors are in stock (delivery within 3 working days); custom orders take 7-15 working days—30% faster than industry averages (10-20 days), helping customers reduce emergency downtime.

Q1: Is this connector compatible with my die-casting machine (e.g., Yizumi DM300)?

Q2: What tools do I need for installation?

Q3: How often do I need to replace the gasket?

Specialized flange connector designed for die-casting equipment’s fluid (coolant, hydraulic oil) transfer systems, focusing on leak prevention and long-term durability.

Compatible with most die-casting machine brands (e.g., LH, Yizumi, Haitian) and adapts to high-temperature (up to 200℃) and high-pressure (up to 16MPa) working environments.

Features corrosion-resistant materials and reinforced sealing structures to reduce maintenance frequency in harsh die-casting workshops.

Supports both standard and custom sizes to match different pipeline diameters (DN15-DN100) in die-casting production lines.

Simplifies installation and replacement, minimizing equipment downtime caused by connector failures.

Visually, the connector has a sleek, matte stainless steel body—no sharp edges, just smooth, uniform surfaces that feel solid and heavy when held, a clear contrast to the flimsy, rough-finished connectors on the market. When installed, it sits tightly against the pump interface, with no visible gaps; when fluid flows through, it emits only a soft, steady hum (below 55 decibels), unlike cheap connectors that rattle or gurgle when under pressure. The sealing gasket, made of high-temperature silicone, has a slightly tacky texture that ensures a tight fit, and the bolts (with anti-rust coating) turn smoothly without sticking, even after months of exposure to die-casting workshop moisture. Every detail—from the laser-etched size markings (clear and scratch-resistant) to the chamfered bolt holes (easy to align during installation)—is designed to make daily use easier for die-casting maintenance teams.

Superior Leak-Proof Performance: Adopts a dual-sealing structure (inner silicone gasket + outer O-ring) that forms a "double barrier" against fluid leakage. In tests, it maintained zero leakage even when subjected to 120% of the rated pressure (19.2MPa) and temperature cycles (20℃-200℃), reducing fluid waste by 90% compared to single-seal connectors. For a die-casting factory using 200L of hydraulic oil monthly, this saves about

Extreme Durability: The main body is made of 316 stainless steel (instead of common 304 stainless steel), which resists corrosion from die-casting workshop’s metal dust and acidic coolants. The material’s surface hardness (HV 210) also prevents scratches from heavy tools during installation, extending the connector’s service life to 5 years—twice that of ordinary carbon steel connectors.

High-Temperature/Pressure Resistance: The silicone sealing gasket is formulated with heat-resistant additives, maintaining elasticity at 200℃ (ordinary gaskets harden and crack at 150℃). The reinforced flange disk (thickness 8mm) withstands up to 16MPa pressure without deformation, making it suitable for die-casting machines’ high-pressure hydraulic systems.

Easy Installation & Replacement: The flange holes are precision-drilled (tolerance ±0.1mm) to align perfectly with standard pump interfaces, eliminating the need for on-site reaming. A maintenance team of 2 can complete replacement in 30 minutes—50% faster than connectors with misaligned holes that often require 1 hour or more.

Dust & Moisture Protection: The joint between the flange and pipeline is covered with a rubber dust cover (removable for inspection) that blocks metal dust from entering the sealing area. This reduces the risk of gasket wear caused by dust particles, cutting maintenance frequency from once every 3 months to once every 12 months.

| Parameter Name | Specification |

| Material (Main Body) | 316 Stainless Steel |

| Material (Sealing Gasket) | High-Temperature Silicone (耐 200℃) |

| Material (Bolts) | Carbon Steel with Zinc-Nickel Coating (Anti-Rust) |

| Rated Pressure | 16MPa |

| Maximum Operating Temperature | 200℃ |

| Minimum Operating Temperature | -40℃ |

| Compatible Fluid Types | Hydraulic Oil, Coolant (Ethylene Glycol-Based), Water-Glycol Mixtures |

| Pipeline Diameter Range | DN15 (1/2") - DN100 (4") |

| Flange Standard | DIN 2501, ANSI B16.5, GB/T 9119 (Customizable) |

| Sealing Structure | Dual-Seal (Inner Gasket + Outer O-Ring) |

| Surface Treatment | Passivation (Anti-Corrosion) |

| Weight | 0.8kg (DN15) - 5.2kg (DN100) |

| Certification | ISO 9001, CE, RoHS |

| Service Life | 5 Years (Under Normal Die-Casting Working Conditions) |

Die-Casting Machine Coolant Circuits: Connects water pumps to mold cooling channels, where its high-temperature resistance (200℃) prevents gasket failure from hot mold heat transfer. A customer in Jiangsu reported that after replacing old connectors, their coolant leakage dropped from 30L/week to less than 3L/week.

Hydraulic System Pipelines: Links hydraulic pumps to die-casting machine cylinders. The 16MPa pressure resistance ensures stable fluid transmission during mold clamping (a process that often generates peak pressure), avoiding sudden pressure drops that cause mold misalignment.

Molten Metal Transfer Auxiliary Systems: Used in cooling water pipelines for molten metal holding furnaces. The 316 stainless steel material resists corrosion from metal oxide dust (common in furnace areas), which previously caused ordinary connectors to rust and leak within 6 months.

Wastewater Treatment Lines: Connects pumps in die-casting workshop wastewater systems, where the dual-seal structure prevents leakage of acidic wastewater (containing metal ions) that could damage factory infrastructure.

Custom Die-Casting Lines: For non-standard die-casting equipment (e.g., large-scale automotive part casting machines), our custom-sized connectors (up to DN100) match unique pipeline designs, eliminating the need for adapter pieces that increase leak risks.

Reduces Operational Costs: The zero-leak design cuts fluid waste (hydraulic oil, coolant) by 90%, and the 5-year service life reduces replacement frequency. A medium-sized die-casting factory (10 machines) saved over $8,000 in annual fluid and maintenance costs after installation.

Minimizes Downtime: Fast installation (30 minutes/unit) and low maintenance needs (once/12 months) reduce equipment downtime caused by connector issues. A customer in Guangdong used to have 2 hours of monthly downtime for connector replacements; now it’s less than 15 minutes.

Improves Workplace Safety: Leak prevention eliminates slippery floors (a major safety hazard in die-casting workshops) and reduces exposure to toxic fluids (e.g., hydraulic oil). Since 2021, none of our customers have reported safety accidents related to this connector.

Enhances Equipment Stability: Stable fluid transmission (no pressure drops or leaks) ensures die-casting machines run at optimal performance. This reduces mold defects caused by unstable cooling or hydraulic pressure—one automotive part manufacturer saw their defect rate drop from 7% to 3%.

Reduces Inventory Burden: Our standard connectors are compatible with multiple die-casting machine brands, so customers don’t need to stock different types for different machines. A small workshop reduced its connector inventory by 60% after switching to our product.

Pre-Installation Checks:

Inspect the connector’s surface for scratches or rust (common during transportation). If found, use 400-grit sandpaper to polish minor scratches, then apply a thin layer of anti-rust oil.

Verify the gasket’s elasticity: Press it gently with your finger—if it bounces back quickly, it’s in good condition; if it stays deformed, replace it (we provide 2 spare gaskets per unit).

Check that the bolt threads are clean (no metal dust) and apply a small amount of high-temperature grease to ensure smooth tightening.

Installation Steps:

Align the connector’s flange holes with the pump/pipeline interface—use a straightedge to confirm no misalignment (max allowed: ±0.5mm).

Place the inner gasket on the interface, then the connector body, then the outer O-ring.

Tighten the bolts in a "cross pattern" (e.g., tighten bolt 1 → bolt 3 → bolt 2 → bolt 4) to ensure even pressure. Torque to 35N·m (for DN15-DN50) or 55N·m (for DN65-DN100) using a torque wrench.

Install the dust cover and connect the fluid pipeline; run a pressure test (1.2× rated pressure for 30 minutes) to confirm no leaks.

Daily & Regular Maintenance:

Daily: Visually inspect the connector for leaks (check for fluid stains around the flange) and ensure the dust cover is intact.

Monthly: Wipe the connector with a dry cloth to remove metal dust—do not use water (may cause rust).

Every 6 Months: Re-tighten the bolts (torque to the original value) to compensate for any gasket compression.

Every 12 Months: Replace the gasket and O-ring (even if no leaks are found) to prevent sudden failure—our spare parts kit includes all necessary components.

Customizable Dimensions: We can adjust the flange diameter (up to DN150), hole number (4-8 holes), and bolt size (M8-M16) to match unique die-casting equipment designs. For example, a customer with a custom 5000-ton die-casting machine needed a DN120 connector; we delivered it in 10 working days.

Material Customization: For extreme conditions (e.g., high-corrosion wastewater), we offer Hastelloy C-276 (a super alloy) instead of 316 stainless steel. For low-temperature environments (e.g., cold storage die-casting workshops), we use nitrile rubber gaskets (resists -60℃).

Sealing Customization: For food-grade die-casting (e.g., aluminum cookware), we provide FDA-certified silicone gaskets; for high-pressure systems (up to 25MPa), we use metal-reinforced gaskets.

Labeling Customization: We can laser-etch your company logo or part number on the connector for easy inventory management—no extra cost for orders over 50 units.

Warranty: 3-year warranty for the main body (316 stainless steel) and 1-year warranty for gaskets/bolts. If the connector leaks due to material defects within the warranty period, we replace it for free and cover shipping costs.

Spare Parts Supply: We stock gaskets, bolts, and dust covers in 3 regional warehouses (Shanghai, Guangzhou, Qingdao). For urgent needs, we offer 24-hour delivery to major die-casting hubs (e.g., Suzhou, Dongguan).

Technical Support: Our team of 5 die-casting fluid system engineers provides 24/7 support via phone, WhatsApp, or video call. For on-site issues, we send an engineer to your workshop within 48 hours (for customers in China) or 72 hours (for international customers).

Installation Training: For bulk orders (over 20 units), we offer free on-site training for your maintenance team—covering installation, pressure testing, and troubleshooting—to ensure correct use.

10 Years of Die-Casting Focus: We’ve specialized in fluid connectors for die-casting equipment since 2014, not general industrial connectors. Our team understands the unique challenges (high temperature, metal dust, frequent pressure cycles) of die-casting workshops, so our products are not "one-size-fits-all" but tailored solutions.

Proven Quality: Our connectors have passed 1,000-hour durability tests in simulated die-casting environments (200℃, 16MPa, metal dust exposure) with no leaks or deformation. We also hold ISO 9001 (quality management) and CE (safety) certifications, meeting international standards for die-casting equipment.

Customer-Centric Cases: Over 800 die-casting enterprises (including 5 of the top 10 Chinese automotive die-casting factories) use our connectors. A major customer (producing aluminum alloy wheels) reported that their connector-related downtime dropped by 92% after switching to our product.

Cost-Effective Solutions: We balance quality and price—our 316 stainless steel connectors cost only 15% more than ordinary 304 connectors but last 2x longer, resulting in lower total cost of ownership (TCO) over 5 years.

Flexible Lead Times: Standard connectors are in stock (delivery within 3 working days); custom orders take 7-15 working days—30% faster than industry averages (10-20 days), helping customers reduce emergency downtime.

Q1: Is this connector compatible with my die-casting machine (e.g., Yizumi DM300)?

Q2: What tools do I need for installation?

Q3: How often do I need to replace the gasket?