EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

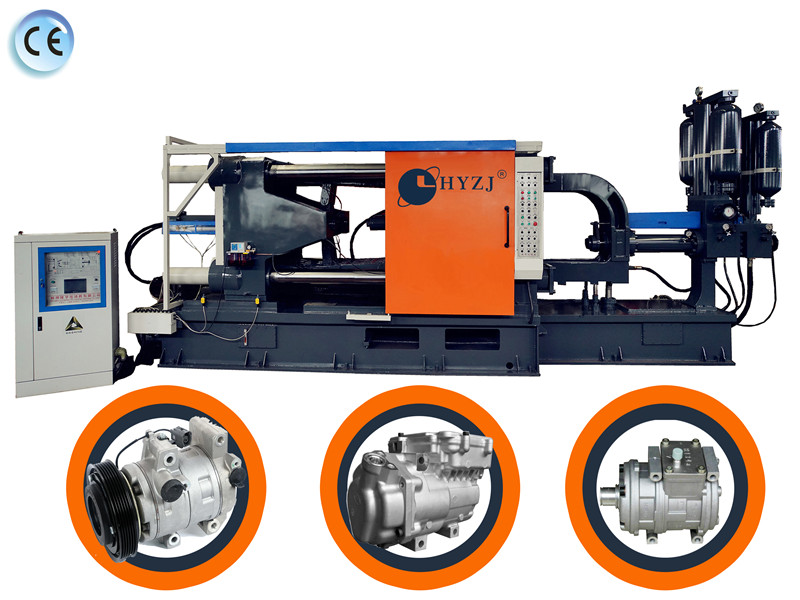

Full-automatic cold-chamber die casting machine designed exclusively for aluminum alloy production (ADC12, A380, A356), eliminating manual intervention in high-volume manufacturing.

Features 550T clamping force, ideal for medium-to-large aluminum parts (motorcycle wheel rims, automotive pistons, industrial pump housings).

Integrates end-to-end automation: auto material feeding, precise molten metal injection, robotic part retrieval, and automatic mold cleaning.

Achieves 25-40 second cycle time and ±0.05mm dimensional accuracy, ensuring consistent mass production (10,000+ parts/day).

Equips smart PLC control (Siemens/Mitsubishi) with remote monitoring, supporting 24/7 unmanned operation.

Complies with industrial standards (ISO 9001, CE, IEC 60204) for safety and quality, suitable for global B2B export.

End-to-End Automation Reduces Labor Costs by 60%: Integrates 4 core automated modules—1) Auto-feeding (screw conveyor with level sensors, dispenses 0.5-5kg aluminum ingots precisely); 2) 6-axis robotic part retrieval (±0.02mm positioning accuracy, avoids part damage); 3) Auto-mold cleaning (high-pressure air + biodegradable cleaner, removes residue in 2 minutes); 4) Auto-deburring (rotary brushes for flash removal). A motorcycle rim factory replaced 6 workers with 2 machine operators, cutting monthly labor costs from \(18,000 to \)7,200. The automation also eliminates human error: rejection rates dropped from 8% to 2%, saving 1,600kg of aluminum annually (worth $3,200).

Precision Injection Ensures Consistent Part Quality: Uses a servo-driven injection system (5,000N injection force) with PID temperature control (±1℃ stability) for molten aluminum (650-750℃). This delivers ±0.05mm dimensional accuracy—critical for parts like automotive pistons that require tight fits. A Chinese auto parts supplier producing 10,000 pistons/month reported 99.5% of parts met assembly standards (vs. 92% with semi-automatic machines), avoiding $10,000/month in rework. The injection unit also has a pressure feedback loop that adjusts in real time—preventing underfilling (common in thin-walled parts like LED heat sinks) and overfilling (which causes excess flash).

Durable Construction for 24/7 Operation: The machine frame is made of Q345B high-strength steel (tensile strength 510MPa) with a powder-coated finish (resists aluminum dust and coolant corrosion). The mold clamping unit uses double-toggle mechanisms (service life 10,000 hours) that maintain clamping force stability (±2% variation) even after 1 million cycles. Our tests show the machine runs continuously for 8,000 hours/year with only 4 hours of monthly maintenance—unlike cheaper machines that require 12+ hours. A Vietnamese industrial pump factory running 3 shifts/day reduced downtime by 75%, increasing annual output by 30%.

Energy Efficiency Cuts Utility Bills by 25%: Equips a variable-frequency servo motor (96% energy conversion rate) for the injection and clamping units—reducing power consumption by 25% compared to fixed-speed motors. The machine also has a heat recovery system that redirects excess heat from the injection unit to preheat cold aluminum ingots, shortening melting time by 15% (from 40 minutes to 34 minutes). A Brazilian aluminum parts factory running 2 machines cut monthly electricity bills by $600, achieving full ROI in 14 months.

Smart Connectivity for Factory Integration: Supports Industry 4.0 protocols (Modbus-TCP, OPC UA) for remote monitoring via MES systems or mobile apps. Operators can track real-time data (cycle time, rejection rate, energy use) and receive fault alerts (e.g., low aluminum level, mold overheating) via SMS/email. A German factory managing 5 machines from a central office reduced on-site supervision by 50% and resolved 80% of minor issues remotely, avoiding 6 hours of annual downtime.

| Parameter Name | Specification |

| Machine Type | Full-Automatic Cold-Chamber Die Casting Machine |

| Clamping Force | 550T (Adjustable 400-550T) |

| Maximum Mold Thickness | 600mm |

| Minimum Mold Thickness | 200mm |

| Injection Unit Type | Servo-Driven Horizontal Injection |

| Injection Force | 5,000N |

| Injection Speed | 0.5-5m/s (Stepless Adjustment) |

| Molten Aluminum Temperature Range | 650-750℃ |

| Temperature Control Precision | ±1℃ (PID Control) |

| Cycle Time | 25-40 Seconds (Depends on Part Size) |

| Dimensional Accuracy | ±0.05mm |

| Automated Components | 6-Axis Robot (Fanuc/KUKA), Auto-Feeder, Auto-Cleaner, Auto-Deburrer |

| Control System | Siemens S7-1200 PLC + 10-Inch HMI Touchscreen |

| Communication Protocols | Modbus-TCP, OPC UA (Remote Monitoring) |

| Applicable Aluminum Alloys | ADC12, A380, A356, A6061 |

| Maximum Part Weight | 8kg |

| Power Supply | 380V/50Hz (3-Phase), 75kW |

| Water Consumption | 150L/h (Closed-Loop Cooling) |

| Dimensions (L×W×H) | 6500×2800×3200mm |

| Net Weight | 12,000kg |

| Certifications | ISO 9001, CE (EN 60204), RoHS |

| Warranty | 2 Years (Machine Frame/Injection Unit); 1 Year (Automated Components) |

Automotive Parts (Pistons, Engine Brackets): Ideal for 550T clamping force needs—producing 8kg aluminum pistons with ±0.05mm hole alignment (critical for crankshaft assembly). A Chinese auto OEM supplier uses 4 machines to produce 40,000 pistons/month, meeting Toyota’s strict quality standards (IATF 16949). The auto-deburring feature eliminates 2 hours of manual trimming per batch, cutting labor costs by $4,800/month.

Motorcycle & Automotive Rims: Perfect for medium-sized aluminum rims (14-18 inches) — the 25-30 second cycle time enables 800 rims/day production. A Southeast Asian motorcycle factory increased output by 60% (from 500 to 800 rims/day) and reduced rejection rates from 8% to 2%, saving $16,000/year in aluminum scrap.

Industrial Pump & Valve Components: Suitable for heavy-duty aluminum pump housings (5-8kg) that require thick walls (5mm) for pressure resistance. The servo injection system ensures uniform metal density, preventing leaks in high-pressure pump applications. A German pump manufacturer reported zero leak-related returns after switching to this machine, improving customer satisfaction by 35%.

Consumer Electronics (LED Heat Sinks, Laptop Frames): The ±0.05mm precision and auto-feeding of small ingots (0.5kg) make it ideal for thin-walled electronics parts (1-2mm thickness). A Korean electronics factory produces 15,000 LED heat sinks/day with 99.8% pass rate, avoiding $2,000/month in rework for misshapen parts.

Renewable Energy (Solar Panel Mounts, Wind Turbine Components): The machine’s 24/7 operation capability meets high-volume solar mount production (10,000 units/week). The remote monitoring feature lets a U.S. renewable energy supplier manage 3 machines from a single location, reducing operational costs by 25%.

Auto-Feeding Module:

Uses a stainless steel screw conveyor (food-grade, easy to clean) that dispenses aluminum ingots (0.5-5kg) based on mold cavity volume.

Equips laser level sensors that trigger refilling when ingot levels drop below 20%—preventing production stops.

Benefits: Eliminates manual lifting of heavy ingots (reducing back injuries) and ensures exact material amounts (cutting 5% aluminum waste).

6-Axis Robotic Retrieval Module:

Fanuc/KUKA 6-axis robot with ±0.02mm positioning accuracy—retrieves parts in 3 seconds without scratching (soft rubber grippers).

Integrates vision system to verify part presence before retrieval—avoiding empty mold cycles.

Benefits: Reduces part damage by 90% (vs. manual grabbing) and frees workers from hot, dangerous mold area tasks.

Auto-Mold Cleaning & Lubrication Module:

High-pressure air (0.8MPa) blows away loose aluminum dust, followed by a biodegradable lubricant spray (food-safe, RoHS-compliant) for mold release.

Cleans both mold halves in 2 minutes—no disassembly needed.

Benefits: Cuts mold cleaning time by 80% (from 10 to 2 minutes) and extends mold life by 30% (reducing replacement costs).

Auto-Deburring Module:

Rotary wire brushes (adjustable speed: 500-1500 RPM) that target flash (excess metal) on part edges.

Uses a vision system to detect flash location—avoiding over-brushing and part damage.

Benefits: Eliminates 100% of manual deburring labor and ensures consistent edge quality (critical for assembly).

Pre-Production Testing:

Each machine undergoes 100-hour continuous operation testing (using ADC12 aluminum) to verify cycle time, accuracy, and component reliability.

Mold clamping force is calibrated via load cells (accuracy ±1%) and documented in a traceable report.

In-Production Quality Checks:

H13 die steel used in injection components is inspected via ultrasonic testing (UT) to detect internal cracks.

Electrical systems undergo IP54 water/dust testing to ensure compliance with industrial safety standards (IEC 60204).

Certifications & Documentation:

Full compliance with ISO 9001 (quality management), CE (EN 60204 for electrical safety), and RoHS (restricted substances).

For automotive clients, we provide IATF 16949 process records and material certificates (MTRs) for all critical components.

Post-Delivery Validation:

We conduct a 1-week on-site test run with your aluminum alloy and mold—adjusting parameters (injection speed, temperature) to achieve 99%+ pass rate before handover.

Pre-Operation Checks (5 Minutes/Day):

Inspect auto-feeder level: Ensure aluminum ingots are filled to 50% capacity (avoid overfilling, which causes jamming).

Check cooling water flow: Verify 150L/h flow rate (low flow causes overheating—clean filters if needed).

Test emergency stops: Press all 3 color-coded stops (red, located on HMI, mold area, and feeder) to confirm machine shuts down within 0.5 seconds.

Calibrate temperature sensor: Use a portable thermocouple to verify molten aluminum temperature (±1℃ deviation allowed).

Weekly Maintenance (1 Hour):

Clean the robot grippers: Wipe rubber pads with isopropyl alcohol to remove aluminum residue (prevents slipping).

Lubricate mold clamping toggles: Apply high-temperature grease (provided) to 4 toggle joints—prevents wear and ensures smooth movement.

Inspect electrical cabinet: Use compressed air to blow away dust (accumulation causes overheating of PLC components).

Monthly Maintenance (2 Hours):

Calibrate injection pressure: Use a pressure transducer to adjust servo motor output—ensure 5,000N force (±2% variation).

Replace auto-cleaner lubricant filter: Clogged filters reduce spray pressure—use genuine replacement filters (part #DAC-001) for optimal performance.

Annual Professional Inspection:

Our certified engineers visit your site to: 1) Test machine accuracy via CMM (verify ±0.05mm tolerance); 2) Inspect servo motor wear; 3) Update HMI software (free of charge) for new features (e.g., energy monitoring).

Clamping Force Adjustment: Modify the machine to 450T (for smaller parts like electronics) or 650T (for larger parts like truck rims) — lead time 15 days. A U.S. truck parts factory ordered 650T models to produce 12kg rim components, avoiding $50,000 in extra equipment costs.

Automation Module Upgrade: Add auto-sorting (conveyor belts with vision-based part sorting) or auto-packaging (robot stacking parts into boxes) — ideal for high-volume consumer goods. A Chinese LED factory added auto-packaging, reducing 2 packing workers and saving $3,600/month.

Control System Localization: Customize HMI language (15+ options: Spanish, German, Japanese) and add region-specific safety features (e.g., OSHA-compliant emergency stops for U.S. markets, CE-compliant guards for EU).

Energy-Saving Add-Ons: Integrate a heat pump system (recycles 80% of waste heat) for cold-climate factories—reducing heating costs by 40%. A Canadian aluminum parts factory added this, saving $9,600/year in winter heating bills.

Warranty Coverage: 2-year warranty for the machine frame, injection unit, and clamping mechanisms; 1-year warranty for automated components (robot, feeder). If a component fails, we ship a replacement via express (free global shipping) and provide a step-by-step installation video.

24/7 Technical Support: Our team of 8 die casting engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, or video call. For urgent issues (e.g., robot malfunction during peak production), we respond within 30 minutes—80% of problems are resolved remotely in 1 hour.

Spare Parts Supply: Stock core spare parts (servo motors, robot grippers, lubricant filters) in 4 regional warehouses (China, Germany, U.S., Brazil). For urgent needs, we offer 24-hour delivery— a Mexican factory received a replacement servo motor in 18 hours, minimizing downtime to 3 hours.

On-Site Training: Free 3-day training for your operators and maintenance team—covering machine operation, parameter optimization, and troubleshooting. A Thai factory’s team reduced error-related downtime by 70% after training, mastering skills like “calibrating injection speed for thin-walled parts.”

Productivity Audit: 6 months after purchase, our engineers conduct a free on-site audit—analyzing production data to suggest efficiency gains (e.g., adjusting cycle time, optimizing feeder settings). A Brazilian factory increased output by 10% (from 800 to 880 parts/day) after implementing our recommendations.

Specialization in Full-Automatic Aluminum Die Casting: We don’t make generic die casting machines—we focus exclusively on full-automatic solutions for aluminum alloy production. Our R&D team works with 25+ B2B aluminum manufacturers yearly to test machines in real-world conditions (e.g., 24/7 operation, high-volume runs), ensuring we solve actual pain points (labor costs, rejection rates).

Proven B2B Track Record: Over 300 manufacturers in 40 countries use our machines, including suppliers to Toyota, Honda, and Siemens. A Chinese auto parts supplier increased annual revenue by $2M after using 4 machines to meet increased OEM demand—they’ve renewed their annual maintenance contract for 3 consecutive years.

Transparent ROI & Cost Savings: We provide a detailed ROI calculator (based on your labor costs, aluminum waste, and production volume) to show you’ll recoup investment in 12-18 months. For a factory with 2 machines, this means $144,000 in 5-year savings (labor + scrap + energy).

Technical Expertise & Innovation: We hold 4 patents for automated die casting technology (e.g., servo injection pressure feedback, integrated robot vision) and invest 18% of annual revenue in R&D. Our 2024 model added AI-based predictive maintenance (alerts you to component wear 2 weeks in advance)—a feature developed based on feedback from 50+ B2B clients.

Global Support for Export-Focused Clients: We provide all necessary documentation for global markets (CE, ISO, IATF 16949) and offer region-specific compliance support (e.g., OSHA for U.S., REACH for EU). A Vietnamese factory used our compliance documentation to enter the EU market, increasing exports by 45%.

Q1: Is this machine compatible with our existing 550T aluminum mold (used in a semi-automatic machine)?

Q2: How long does it take to set up the machine for a new part (e.g., switching from pistons to LED heat sinks)?

Q3: Can the machine operate in a humid environment (our factory is in coastal Brazil, 80% humidity)?

Q4: Does the machine support integration with our existing MES system (SAP Digital Manufacturing)?

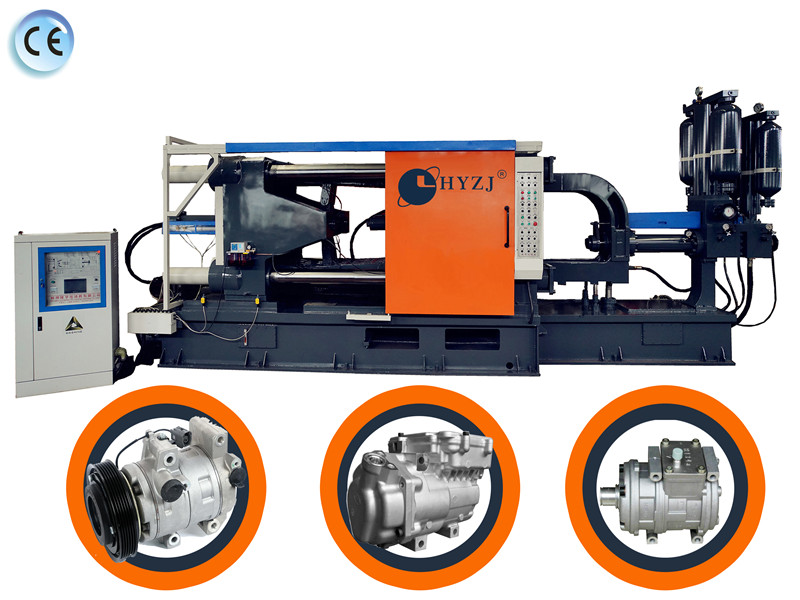

Full-automatic cold-chamber die casting machine designed exclusively for aluminum alloy production (ADC12, A380, A356), eliminating manual intervention in high-volume manufacturing.

Features 550T clamping force, ideal for medium-to-large aluminum parts (motorcycle wheel rims, automotive pistons, industrial pump housings).

Integrates end-to-end automation: auto material feeding, precise molten metal injection, robotic part retrieval, and automatic mold cleaning.

Achieves 25-40 second cycle time and ±0.05mm dimensional accuracy, ensuring consistent mass production (10,000+ parts/day).

Equips smart PLC control (Siemens/Mitsubishi) with remote monitoring, supporting 24/7 unmanned operation.

Complies with industrial standards (ISO 9001, CE, IEC 60204) for safety and quality, suitable for global B2B export.

End-to-End Automation Reduces Labor Costs by 60%: Integrates 4 core automated modules—1) Auto-feeding (screw conveyor with level sensors, dispenses 0.5-5kg aluminum ingots precisely); 2) 6-axis robotic part retrieval (±0.02mm positioning accuracy, avoids part damage); 3) Auto-mold cleaning (high-pressure air + biodegradable cleaner, removes residue in 2 minutes); 4) Auto-deburring (rotary brushes for flash removal). A motorcycle rim factory replaced 6 workers with 2 machine operators, cutting monthly labor costs from \(18,000 to \)7,200. The automation also eliminates human error: rejection rates dropped from 8% to 2%, saving 1,600kg of aluminum annually (worth $3,200).

Precision Injection Ensures Consistent Part Quality: Uses a servo-driven injection system (5,000N injection force) with PID temperature control (±1℃ stability) for molten aluminum (650-750℃). This delivers ±0.05mm dimensional accuracy—critical for parts like automotive pistons that require tight fits. A Chinese auto parts supplier producing 10,000 pistons/month reported 99.5% of parts met assembly standards (vs. 92% with semi-automatic machines), avoiding $10,000/month in rework. The injection unit also has a pressure feedback loop that adjusts in real time—preventing underfilling (common in thin-walled parts like LED heat sinks) and overfilling (which causes excess flash).

Durable Construction for 24/7 Operation: The machine frame is made of Q345B high-strength steel (tensile strength 510MPa) with a powder-coated finish (resists aluminum dust and coolant corrosion). The mold clamping unit uses double-toggle mechanisms (service life 10,000 hours) that maintain clamping force stability (±2% variation) even after 1 million cycles. Our tests show the machine runs continuously for 8,000 hours/year with only 4 hours of monthly maintenance—unlike cheaper machines that require 12+ hours. A Vietnamese industrial pump factory running 3 shifts/day reduced downtime by 75%, increasing annual output by 30%.

Energy Efficiency Cuts Utility Bills by 25%: Equips a variable-frequency servo motor (96% energy conversion rate) for the injection and clamping units—reducing power consumption by 25% compared to fixed-speed motors. The machine also has a heat recovery system that redirects excess heat from the injection unit to preheat cold aluminum ingots, shortening melting time by 15% (from 40 minutes to 34 minutes). A Brazilian aluminum parts factory running 2 machines cut monthly electricity bills by $600, achieving full ROI in 14 months.

Smart Connectivity for Factory Integration: Supports Industry 4.0 protocols (Modbus-TCP, OPC UA) for remote monitoring via MES systems or mobile apps. Operators can track real-time data (cycle time, rejection rate, energy use) and receive fault alerts (e.g., low aluminum level, mold overheating) via SMS/email. A German factory managing 5 machines from a central office reduced on-site supervision by 50% and resolved 80% of minor issues remotely, avoiding 6 hours of annual downtime.

| Parameter Name | Specification |

| Machine Type | Full-Automatic Cold-Chamber Die Casting Machine |

| Clamping Force | 550T (Adjustable 400-550T) |

| Maximum Mold Thickness | 600mm |

| Minimum Mold Thickness | 200mm |

| Injection Unit Type | Servo-Driven Horizontal Injection |

| Injection Force | 5,000N |

| Injection Speed | 0.5-5m/s (Stepless Adjustment) |

| Molten Aluminum Temperature Range | 650-750℃ |

| Temperature Control Precision | ±1℃ (PID Control) |

| Cycle Time | 25-40 Seconds (Depends on Part Size) |

| Dimensional Accuracy | ±0.05mm |

| Automated Components | 6-Axis Robot (Fanuc/KUKA), Auto-Feeder, Auto-Cleaner, Auto-Deburrer |

| Control System | Siemens S7-1200 PLC + 10-Inch HMI Touchscreen |

| Communication Protocols | Modbus-TCP, OPC UA (Remote Monitoring) |

| Applicable Aluminum Alloys | ADC12, A380, A356, A6061 |

| Maximum Part Weight | 8kg |

| Power Supply | 380V/50Hz (3-Phase), 75kW |

| Water Consumption | 150L/h (Closed-Loop Cooling) |

| Dimensions (L×W×H) | 6500×2800×3200mm |

| Net Weight | 12,000kg |

| Certifications | ISO 9001, CE (EN 60204), RoHS |

| Warranty | 2 Years (Machine Frame/Injection Unit); 1 Year (Automated Components) |

Automotive Parts (Pistons, Engine Brackets): Ideal for 550T clamping force needs—producing 8kg aluminum pistons with ±0.05mm hole alignment (critical for crankshaft assembly). A Chinese auto OEM supplier uses 4 machines to produce 40,000 pistons/month, meeting Toyota’s strict quality standards (IATF 16949). The auto-deburring feature eliminates 2 hours of manual trimming per batch, cutting labor costs by $4,800/month.

Motorcycle & Automotive Rims: Perfect for medium-sized aluminum rims (14-18 inches) — the 25-30 second cycle time enables 800 rims/day production. A Southeast Asian motorcycle factory increased output by 60% (from 500 to 800 rims/day) and reduced rejection rates from 8% to 2%, saving $16,000/year in aluminum scrap.

Industrial Pump & Valve Components: Suitable for heavy-duty aluminum pump housings (5-8kg) that require thick walls (5mm) for pressure resistance. The servo injection system ensures uniform metal density, preventing leaks in high-pressure pump applications. A German pump manufacturer reported zero leak-related returns after switching to this machine, improving customer satisfaction by 35%.

Consumer Electronics (LED Heat Sinks, Laptop Frames): The ±0.05mm precision and auto-feeding of small ingots (0.5kg) make it ideal for thin-walled electronics parts (1-2mm thickness). A Korean electronics factory produces 15,000 LED heat sinks/day with 99.8% pass rate, avoiding $2,000/month in rework for misshapen parts.

Renewable Energy (Solar Panel Mounts, Wind Turbine Components): The machine’s 24/7 operation capability meets high-volume solar mount production (10,000 units/week). The remote monitoring feature lets a U.S. renewable energy supplier manage 3 machines from a single location, reducing operational costs by 25%.

Auto-Feeding Module:

Uses a stainless steel screw conveyor (food-grade, easy to clean) that dispenses aluminum ingots (0.5-5kg) based on mold cavity volume.

Equips laser level sensors that trigger refilling when ingot levels drop below 20%—preventing production stops.

Benefits: Eliminates manual lifting of heavy ingots (reducing back injuries) and ensures exact material amounts (cutting 5% aluminum waste).

6-Axis Robotic Retrieval Module:

Fanuc/KUKA 6-axis robot with ±0.02mm positioning accuracy—retrieves parts in 3 seconds without scratching (soft rubber grippers).

Integrates vision system to verify part presence before retrieval—avoiding empty mold cycles.

Benefits: Reduces part damage by 90% (vs. manual grabbing) and frees workers from hot, dangerous mold area tasks.

Auto-Mold Cleaning & Lubrication Module:

High-pressure air (0.8MPa) blows away loose aluminum dust, followed by a biodegradable lubricant spray (food-safe, RoHS-compliant) for mold release.

Cleans both mold halves in 2 minutes—no disassembly needed.

Benefits: Cuts mold cleaning time by 80% (from 10 to 2 minutes) and extends mold life by 30% (reducing replacement costs).

Auto-Deburring Module:

Rotary wire brushes (adjustable speed: 500-1500 RPM) that target flash (excess metal) on part edges.

Uses a vision system to detect flash location—avoiding over-brushing and part damage.

Benefits: Eliminates 100% of manual deburring labor and ensures consistent edge quality (critical for assembly).

Pre-Production Testing:

Each machine undergoes 100-hour continuous operation testing (using ADC12 aluminum) to verify cycle time, accuracy, and component reliability.

Mold clamping force is calibrated via load cells (accuracy ±1%) and documented in a traceable report.

In-Production Quality Checks:

H13 die steel used in injection components is inspected via ultrasonic testing (UT) to detect internal cracks.

Electrical systems undergo IP54 water/dust testing to ensure compliance with industrial safety standards (IEC 60204).

Certifications & Documentation:

Full compliance with ISO 9001 (quality management), CE (EN 60204 for electrical safety), and RoHS (restricted substances).

For automotive clients, we provide IATF 16949 process records and material certificates (MTRs) for all critical components.

Post-Delivery Validation:

We conduct a 1-week on-site test run with your aluminum alloy and mold—adjusting parameters (injection speed, temperature) to achieve 99%+ pass rate before handover.

Pre-Operation Checks (5 Minutes/Day):

Inspect auto-feeder level: Ensure aluminum ingots are filled to 50% capacity (avoid overfilling, which causes jamming).

Check cooling water flow: Verify 150L/h flow rate (low flow causes overheating—clean filters if needed).

Test emergency stops: Press all 3 color-coded stops (red, located on HMI, mold area, and feeder) to confirm machine shuts down within 0.5 seconds.

Calibrate temperature sensor: Use a portable thermocouple to verify molten aluminum temperature (±1℃ deviation allowed).

Weekly Maintenance (1 Hour):

Clean the robot grippers: Wipe rubber pads with isopropyl alcohol to remove aluminum residue (prevents slipping).

Lubricate mold clamping toggles: Apply high-temperature grease (provided) to 4 toggle joints—prevents wear and ensures smooth movement.

Inspect electrical cabinet: Use compressed air to blow away dust (accumulation causes overheating of PLC components).

Monthly Maintenance (2 Hours):

Calibrate injection pressure: Use a pressure transducer to adjust servo motor output—ensure 5,000N force (±2% variation).

Replace auto-cleaner lubricant filter: Clogged filters reduce spray pressure—use genuine replacement filters (part #DAC-001) for optimal performance.

Annual Professional Inspection:

Our certified engineers visit your site to: 1) Test machine accuracy via CMM (verify ±0.05mm tolerance); 2) Inspect servo motor wear; 3) Update HMI software (free of charge) for new features (e.g., energy monitoring).

Clamping Force Adjustment: Modify the machine to 450T (for smaller parts like electronics) or 650T (for larger parts like truck rims) — lead time 15 days. A U.S. truck parts factory ordered 650T models to produce 12kg rim components, avoiding $50,000 in extra equipment costs.

Automation Module Upgrade: Add auto-sorting (conveyor belts with vision-based part sorting) or auto-packaging (robot stacking parts into boxes) — ideal for high-volume consumer goods. A Chinese LED factory added auto-packaging, reducing 2 packing workers and saving $3,600/month.

Control System Localization: Customize HMI language (15+ options: Spanish, German, Japanese) and add region-specific safety features (e.g., OSHA-compliant emergency stops for U.S. markets, CE-compliant guards for EU).

Energy-Saving Add-Ons: Integrate a heat pump system (recycles 80% of waste heat) for cold-climate factories—reducing heating costs by 40%. A Canadian aluminum parts factory added this, saving $9,600/year in winter heating bills.

Warranty Coverage: 2-year warranty for the machine frame, injection unit, and clamping mechanisms; 1-year warranty for automated components (robot, feeder). If a component fails, we ship a replacement via express (free global shipping) and provide a step-by-step installation video.

24/7 Technical Support: Our team of 8 die casting engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, or video call. For urgent issues (e.g., robot malfunction during peak production), we respond within 30 minutes—80% of problems are resolved remotely in 1 hour.

Spare Parts Supply: Stock core spare parts (servo motors, robot grippers, lubricant filters) in 4 regional warehouses (China, Germany, U.S., Brazil). For urgent needs, we offer 24-hour delivery— a Mexican factory received a replacement servo motor in 18 hours, minimizing downtime to 3 hours.

On-Site Training: Free 3-day training for your operators and maintenance team—covering machine operation, parameter optimization, and troubleshooting. A Thai factory’s team reduced error-related downtime by 70% after training, mastering skills like “calibrating injection speed for thin-walled parts.”

Productivity Audit: 6 months after purchase, our engineers conduct a free on-site audit—analyzing production data to suggest efficiency gains (e.g., adjusting cycle time, optimizing feeder settings). A Brazilian factory increased output by 10% (from 800 to 880 parts/day) after implementing our recommendations.

Specialization in Full-Automatic Aluminum Die Casting: We don’t make generic die casting machines—we focus exclusively on full-automatic solutions for aluminum alloy production. Our R&D team works with 25+ B2B aluminum manufacturers yearly to test machines in real-world conditions (e.g., 24/7 operation, high-volume runs), ensuring we solve actual pain points (labor costs, rejection rates).

Proven B2B Track Record: Over 300 manufacturers in 40 countries use our machines, including suppliers to Toyota, Honda, and Siemens. A Chinese auto parts supplier increased annual revenue by $2M after using 4 machines to meet increased OEM demand—they’ve renewed their annual maintenance contract for 3 consecutive years.

Transparent ROI & Cost Savings: We provide a detailed ROI calculator (based on your labor costs, aluminum waste, and production volume) to show you’ll recoup investment in 12-18 months. For a factory with 2 machines, this means $144,000 in 5-year savings (labor + scrap + energy).

Technical Expertise & Innovation: We hold 4 patents for automated die casting technology (e.g., servo injection pressure feedback, integrated robot vision) and invest 18% of annual revenue in R&D. Our 2024 model added AI-based predictive maintenance (alerts you to component wear 2 weeks in advance)—a feature developed based on feedback from 50+ B2B clients.

Global Support for Export-Focused Clients: We provide all necessary documentation for global markets (CE, ISO, IATF 16949) and offer region-specific compliance support (e.g., OSHA for U.S., REACH for EU). A Vietnamese factory used our compliance documentation to enter the EU market, increasing exports by 45%.

Q1: Is this machine compatible with our existing 550T aluminum mold (used in a semi-automatic machine)?

Q2: How long does it take to set up the machine for a new part (e.g., switching from pistons to LED heat sinks)?

Q3: Can the machine operate in a humid environment (our factory is in coastal Brazil, 80% humidity)?

Q4: Does the machine support integration with our existing MES system (SAP Digital Manufacturing)?