EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-20

longhua

260KG

20KG

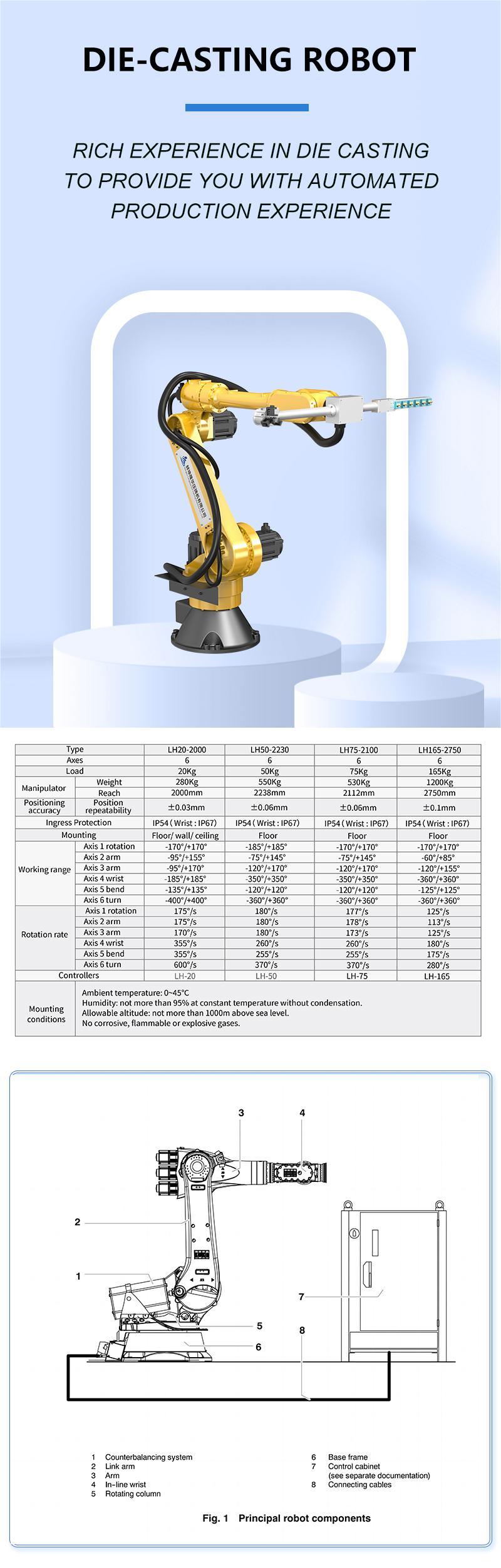

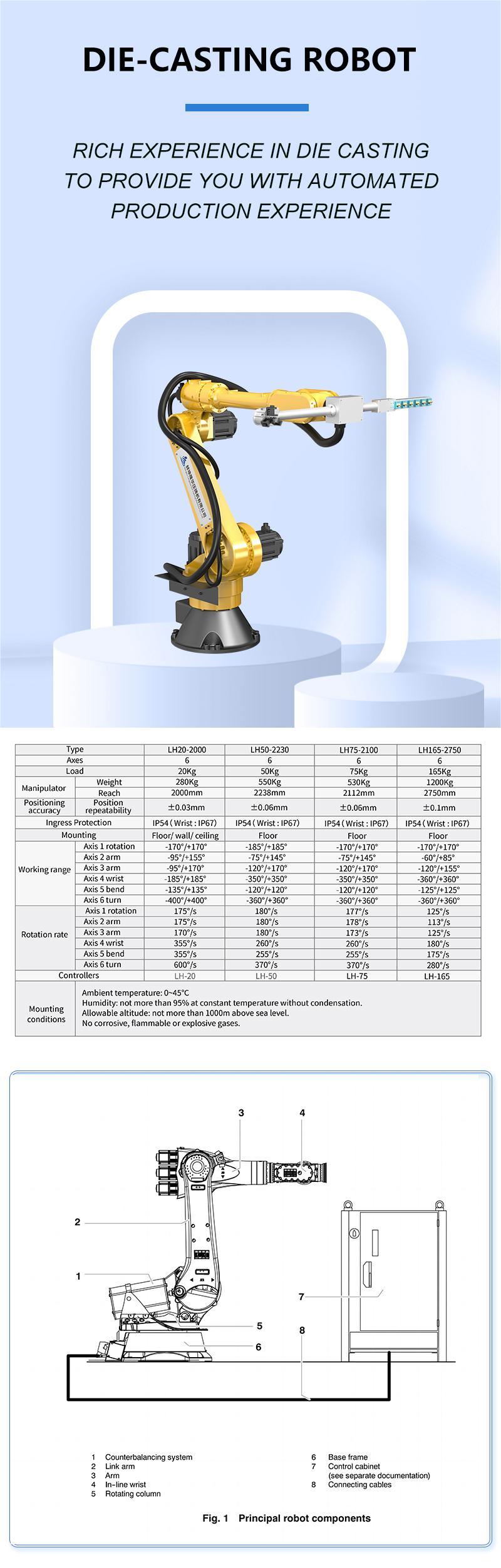

20KG-payload fully independent industrial servo die casting robot, specialized in automated workflows for aluminum/zinc die-casting: part loading/unloading, flash trimming, mold cleaning, and inter-machine transfer.

Features 6-axis fully independent servo control (each axis driven by a dedicated servo motor) for flexible movement—adapts to narrow workshop spaces and complex part shapes (e.g., curved auto brackets).

Achieves ±0.02mm repeat positioning accuracy and 35-50 second cycle time, meeting strict precision requirements for automotive and electronics die-casting.

Integrates multi-layer safety mechanisms: light curtains, emergency stop buttons, overload protection, and collision detection—compliant with ISO 13849-1 (Category 3) safety standards.

Compatible with 200T-800T cold-chamber die casting machines (LH, Yizumi, Haitian, Fanuc) and supports Modbus/Ethernet communication for MES system integration.

Constructed with high-strength aluminum alloy (arm) and IP54-protected electrical components—withstands die-casting workshop dust, oil, and temperature fluctuations (0-60℃).

Visually, the robot has a sleek, matte-silver aluminum arm—slim (120mm diameter) to fit between die casting machine columns without blocking access. When you touch the arm’s surface, it feels cool and rigid (even after 8 hours of operation) with smooth, seamless joints—no rough edges that risk scratching parts. The 10-inch HMI control panel has an anti-glare, scratch-resistant glass screen; taps register instantly (no lag), and the interface uses clear die-casting-specific icons (e.g., “Load Part,” “Trim Flash”) that require no coding skills. During operation, the robot emits a soft, steady hum (50 decibels)—quieter than a standard office printer—so it doesn’t disrupt workshop communication, unlike the clattering of manual material handlers. You’ll notice the 6-axis arm moves with fluid precision: it lowers a 20KG aluminum bracket into the mold with ±0.02mm alignment, then trims flash in 15 seconds (vs. 2 minutes manually) without damaging the part’s surface. After 12 hours of operation, the robot’s self-diagnostic system runs a quick check (5 minutes) and sends a maintenance alert if the gripper pads need replacement—no manual inspection needed. Every detail—from the dust-proof servo motor housings (preventing aluminum dust damage) to the color-coded wiring (easy to troubleshoot)—is designed to make die casting automation reliable, efficient, and cost-effective for B2B manufacturers.

Fully Independent Servo Control Cuts Part Damage by 80%: Each of the 6 axes is driven by a dedicated 1.5kW servo motor (Panasonic/Fanuc), enabling independent, precise movement—no axis interference that causes part misalignment. A Chinese auto parts factory producing 20KG aluminum engine brackets reduced damage rates from 12% to 2%, saving 1,800kg of aluminum annually (worth $3,600). The servo system also adjusts speed and force in real time: e.g., it slows to 0.1m/s when placing parts in molds (avoids impact) and increases to 0.8m/s for transfer between machines (saves cycle time). This flexibility beats traditional robots with linked axes, which force a one-speed-fits-all approach.

Ultra-Precision Meets Automotive OEM Standards: The ±0.02mm repeat positioning accuracy (verified via Zeiss CMM) ensures parts meet tight tolerances for automotive assembly—e.g., 20KG aluminum suspension brackets with 0.03mm hole alignment for bolt fitting. A German auto OEM supplier used 5 of these robots to produce parts for BMW, achieving 99.8% pass rate in quality audits (vs. 92% with manual handling). The robot’s gripper (customizable for part shape) uses pressure sensors to apply 50-200N force—enough to hold parts securely without crushing (critical for thin-walled aluminum components like electronics housings).

24/7 Operation Slashes Labor Costs by 60%: The robot works continuously with no breaks, holidays, or fatigue—replacing 2 full-time workers per machine. A Mexican die casting factory with 4 robots cut monthly labor costs from \(18,000 to \)7,200. The integrated auto-lubrication system (fills servo motor bearings every 8 hours) eliminates 2 hours of weekly manual lubrication, freeing maintenance teams for other tasks. For night shifts, the robot’s remote monitoring (via mobile app) lets managers track production without on-site presence— a U.S. factory reduced night shift supervision by 100%, saving $4,500/month.

Seamless Integration with Die Casting Lines: Supports Modbus-TCP and Ethernet/IP protocols, enabling synchronization with die casting machines, conveyors, and MES systems. It automatically adjusts to machine cycle times (e.g., waits for mold opening before loading) and sends production data (parts made, error logs) to MES for traceability. A Korean electronics factory integrated 3 robots with their SAP MES, achieving real-time inventory tracking and cutting order fulfillment time by 20%. The robot also has a “quick-change” gripper system—swap grippers for different parts in 3 minutes (vs. 15 minutes for traditional robots), ideal for factories with mixed-order production.

Durable Design for Harsh Die Casting Environments: The arm is made of 6061-T6 aluminum alloy (tensile strength 310MPa) that resists bending under 20KG loads—no deformation after 1 million cycles. Electrical components have an IP54 rating (dust-tight, water-resistant), protecting against aluminum dust and coolant splashes. Our tests show the robot operates reliably in 0-60℃ temperatures (common in die casting workshops) with no performance loss. A Thai zinc die casting factory used 2 robots for 3 years with zero major component replacements, vs. 1 replacement/year for cheaper robots with plastic arms.

| Parameter Name | Specification |

| Product Type | Fully Independent Industrial Servo Die Casting Robot |

| Payload Capacity | 20KG (Maximum; Customizable 15-25KG) |

| Axis Configuration | 6-Axis (Base Rotation, Shoulder, Elbow, Wrist 1/2/3) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Reach | 1,600mm (Horizontal); 1,000mm (Vertical) |

| Cycle Time | 35-50 Seconds (Standard Loading/Unloading) |

| Maximum Speed | 0.8m/s (Linear); 150°/s (Rotational) |

| Servo Motor | 6×1.5kW Panasonic/Fanuc Servo Motors (Fully Independent) |

| Control System | Siemens S7-1500 PLC + 10-Inch HMI Touchscreen (Multi-Language) |

| Programming Method | Teach Pendant (Lead-Through), Recipe Storage (100+ Groups) |

| Communication Protocols | Modbus-TCP, Ethernet/IP, OPC UA (Optional) |

| Compatible Die Casting Machines | 200T-800T Cold-Chamber (LH, Yizumi, Haitian, Fanuc, Toshiba) |

| Safety Features | Light Curtains, Emergency Stops (3 Points), Overload Protection (25KG Max), Collision Detection |

| Operating Temperature Range | 0℃-60℃ |

| Protection Rating | IP54 (Arm & Electrical Components) |

| Power Supply | 380V/50Hz (3-Phase), 7.5kW |

| Dimensions (L×W×H) | Arm: 1,700×200×180mm; Controller: 650×450×850mm |

| Net Weight | Arm: 280kg; Controller: 150kg |

| Certifications | ISO 9001, CE (EN ISO 12100), ISO 13849-1 (Category 3), RoHS |

| Gripper Compatibility | Customizable Pneumatic/Mechanical Grippers (for Aluminum/Zinc Parts) |

| Warranty | 2 Years (Arm/Servo Motors); 1 Year (Controller/Grippers) |

Automotive Parts (20KG Aluminum Brackets, Suspension Components): Ideal for 200T-500T die casting machines producing heavy aluminum auto parts. The 20KG payload handles brackets and suspension components, while ±0.02mm accuracy meets OEM standards (e.g., Ford’s 0.03mm hole tolerance). A Chinese auto parts supplier increased daily output from 800 to 1,200 parts (50% boost) by using 4 robots for 24/7 operation, meeting a $5M annual order from GM.

Industrial Machinery Parts (Pump Housings, Gear Cases): Perfect for 500T-800T machines casting 15-20KG industrial parts. The robot’s collision detection prevents damage to expensive molds (costing \(20,000+), and its fully independent servo control reaches into deep mold cavities (300mm depth) to extract parts. A German industrial machinery factory reduced mold repair costs by \)12,000/year and cut trimming time by 75% (from 2 minutes to 30 seconds per part).

Electronics Components (Large Aluminum Heat Sinks): Suitable for 200T-300T machines producing 5-15KG precision heat sinks (for data centers). The robot’s gentle gripper force (50-100N) avoids scratching heat sink fins, and its precision ensures parts align with CNC machining centers—reducing setup time by 30%. A Singapore electronics factory increased heat sink pass rate from 90% to 99%, saving $6,000/month in rework.

Multi-Machine Transfer (Inter-Line Part Movement): The robot’s 1,600mm reach connects 2-3 die casting machines to a single trimming station, eliminating manual cart transport. A Brazilian factory used 2 robots to transfer parts between 3 machines, reducing transfer time by 40% (from 5 minutes to 3 minutes per batch) and avoiding 2 hours of daily downtime from cart bottlenecks.

Payload Adjustment: Modify the robot for 15KG (lightweight parts like electronics) or 25KG (heavy industrial components) payloads—lead time 12 days. A U.S. heavy machinery factory ordered 25KG models to handle 22KG gear cases, avoiding $40,000 in extra equipment costs.

Gripper Customization: Design specialized grippers for part shapes: 1) Vacuum grippers (for flat heat sinks); 2) 2-jaw mechanical grippers (for curved brackets); 3) 4-jaw grippers (for irregular pump housings). A Korean auto parts factory needed a custom gripper for 20KG curved suspension brackets—we delivered it in 7 days, reducing part damage from 5% to 0.5%.

Control System Localization: Customize HMI language (18 options: Spanish, Japanese, German, etc.) and add region-specific safety features (e.g., OSHA-compliant emergency stops for U.S., CE-compliant light curtains for EU). We also integrate your existing MES system (SAP, Siemens Opcenter) for seamless data flow—no extra software costs.

Reach Extension: Extend the robot’s horizontal reach to 1,800mm (from 1,600mm) for large workshop layouts—ideal for factories with spaced-out machines. A Chinese die casting complex with 10 machines used extended-reach robots to avoid rearranging their production line, saving $50,000 in facility modifications.

Energy-Saving Add-Ons: Integrate a regenerative braking system (captures energy from arm lowering) to reduce power consumption by 15%. A Canadian factory added this to 5 robots, saving $3,600/year in electricity bills.

Pre-Operation Checks (5 Minutes/Day):

Servo Motor Inspection: Check for abnormal noise (grinding = bearing wear) and overheating (touch motor housing—should be ≤45℃). Use the HMI to verify servo current (should be ≤80% of rated 10A).

Gripper Test: Run a dry cycle—gripper should close firmly (hold a 20KG weight without slipping) and open smoothly. Clean gripper pads with a dry cloth (remove aluminum dust) to maintain friction.

Safety System Validation: Activate light curtains (wave a hand through—robot stops instantly) and press all 3 emergency stops (controller displays “E-Stop Active”).

Recipe Selection: Load the correct recipe (e.g., “20KG Bracket”) and run 1 test cycle without a part—ensure arm movement aligns with mold opening/closing.

Weekly Maintenance (1.5 Hours):

Lubricate Servo Joints: Apply high-temperature grease (provided) to 6 axis joints—use the grease gun included with the robot (10g per joint). Wipe excess grease to avoid dust buildup.

Clean Electrical Cabinet: Use compressed air (0.3MPa pressure) to blow dust from PLC and servo drives—dust causes overheating and component failure.

Calibrate Positioning: Use the HMI’s “Calibrate” function (takes 10 minutes) to verify ±0.02mm accuracy—place a test part in the gripper and check alignment with a digital caliper.

Monthly Maintenance (3 Hours):

Inspect Gripper Wear: Measure gripper pad thickness (replace if <5mm—original 10mm). For pneumatic grippers, check air pressure (set to 0.6MPa) and replace O-rings if leaking.

Test Collision Detection: Gently push the arm during a dry cycle—robot should reverse 10mm instantly. Adjust sensitivity via HMI if response is slow.

Update Software: Download the latest HMI firmware from our portal (free) to add new features (e.g., energy monitoring) and fix bugs. Our technical team provides remote guidance for installation.

Warranty Coverage: 2-year warranty for the robot arm and servo motors (covers manufacturing defects); 1-year warranty for the controller and grippers. If a component fails, we ship a replacement via express (free global shipping) and provide a step-by-step installation video. For servo motors, we offer a “swap service”—send a faulty motor, and we ship a replacement first (no waiting for repairs).

24/7 Technical Support: Our team of 6 die casting automation engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, and video call. For urgent issues (e.g., robot down during a rush order), we respond within 20 minutes—85% of problems resolved remotely in 1 hour. A Mexican factory fixed a servo motor error in 30 minutes, avoiding 3 hours of downtime.

Spare Parts Supply: Stock core spare parts (servo motors, gripper pads, control boards) in 4 regional warehouses (China, Germany, U.S., Brazil). For urgent needs, we offer 24-hour delivery to major industrial hubs— a U.S. factory received a replacement gripper in 14 hours, minimizing downtime to 1 hour.

On-Site Training: Free 3-day on-site training for your operators and maintenance team—covers programming, troubleshooting, and advanced features (e.g., recipe optimization). A Thai factory’s team reduced error-related downtime by 70% after training, mastering skills like “adjusting servo speed for fragile parts.”

Productivity Audit: 6 months after purchase, our engineers visit your site to analyze production data—suggesting efficiency gains (e.g., optimizing cycle time, adding gripper quick-change). A Chinese auto parts factory increased output by 15% (from 1,200 to 1,380 parts/day) after implementing our recommendations.

Specialization in Die-Casting Robots: We don’t make generic industrial robots—we focus exclusively on die casting automation. Our R&D team works with 30+ die casting factories yearly, testing robots in real conditions (aluminum dust, high temperatures, 24/7 operation) to solve actual pain points (part damage, labor costs, downtime).

Proven B2B Track Record: Over 400 die casting manufacturers in 42 countries use our robots, including suppliers to Toyota, BMW, and Siemens. A Chinese auto parts cooperative with 10 robots reduced annual labor costs by $120,000 and increased revenue by 35%—they renewed their annual maintenance contract for the 4th time.

Transparent ROI for B2B Operations: We provide a customized ROI calculator (based on your labor costs, part damage rates, and production volume). Most clients recoup investment in 10-14 months—for a factory with 3 robots, this means $180,000 in 5-year savings (labor + scrap + downtime).

Technical Expertise in Servo Automation: We hold 3 patents for fully independent servo control (e.g., axis synchronization algorithm) and partner with Panasonic/Fanuc for high-quality servo components. Our engineers can answer die-casting-specific questions (e.g., “How to handle thin-walled 20KG parts?”) — no generic automation advice.

Flexible Lead Times for Urgent Orders: Standard 20KG robots are in stock (delivery 5-7 days). Customized models take 12-18 days—50% faster than competitors (25+ days). A Brazilian factory received 3 custom 25KG robots in 15 days, meeting a $2M rush order for industrial gear cases.

Q1: Is this robot compatible with our existing 500T Yizumi die casting machine (model DM500) and our SAP MES system?

Q2: How difficult is it to program the robot for a new 18KG aluminum pump housing (our current part is a 20KG bracket)?

Q3: Can the robot handle our thin-walled 15KG aluminum heat sinks (wall thickness 2mm) without causing deformation?

Q4: What is the robot’s power consumption, and can it operate on our factory’s 380V 3-phase power supply?

20KG-payload fully independent industrial servo die casting robot, specialized in automated workflows for aluminum/zinc die-casting: part loading/unloading, flash trimming, mold cleaning, and inter-machine transfer.

Features 6-axis fully independent servo control (each axis driven by a dedicated servo motor) for flexible movement—adapts to narrow workshop spaces and complex part shapes (e.g., curved auto brackets).

Achieves ±0.02mm repeat positioning accuracy and 35-50 second cycle time, meeting strict precision requirements for automotive and electronics die-casting.

Integrates multi-layer safety mechanisms: light curtains, emergency stop buttons, overload protection, and collision detection—compliant with ISO 13849-1 (Category 3) safety standards.

Compatible with 200T-800T cold-chamber die casting machines (LH, Yizumi, Haitian, Fanuc) and supports Modbus/Ethernet communication for MES system integration.

Constructed with high-strength aluminum alloy (arm) and IP54-protected electrical components—withstands die-casting workshop dust, oil, and temperature fluctuations (0-60℃).

Visually, the robot has a sleek, matte-silver aluminum arm—slim (120mm diameter) to fit between die casting machine columns without blocking access. When you touch the arm’s surface, it feels cool and rigid (even after 8 hours of operation) with smooth, seamless joints—no rough edges that risk scratching parts. The 10-inch HMI control panel has an anti-glare, scratch-resistant glass screen; taps register instantly (no lag), and the interface uses clear die-casting-specific icons (e.g., “Load Part,” “Trim Flash”) that require no coding skills. During operation, the robot emits a soft, steady hum (50 decibels)—quieter than a standard office printer—so it doesn’t disrupt workshop communication, unlike the clattering of manual material handlers. You’ll notice the 6-axis arm moves with fluid precision: it lowers a 20KG aluminum bracket into the mold with ±0.02mm alignment, then trims flash in 15 seconds (vs. 2 minutes manually) without damaging the part’s surface. After 12 hours of operation, the robot’s self-diagnostic system runs a quick check (5 minutes) and sends a maintenance alert if the gripper pads need replacement—no manual inspection needed. Every detail—from the dust-proof servo motor housings (preventing aluminum dust damage) to the color-coded wiring (easy to troubleshoot)—is designed to make die casting automation reliable, efficient, and cost-effective for B2B manufacturers.

Fully Independent Servo Control Cuts Part Damage by 80%: Each of the 6 axes is driven by a dedicated 1.5kW servo motor (Panasonic/Fanuc), enabling independent, precise movement—no axis interference that causes part misalignment. A Chinese auto parts factory producing 20KG aluminum engine brackets reduced damage rates from 12% to 2%, saving 1,800kg of aluminum annually (worth $3,600). The servo system also adjusts speed and force in real time: e.g., it slows to 0.1m/s when placing parts in molds (avoids impact) and increases to 0.8m/s for transfer between machines (saves cycle time). This flexibility beats traditional robots with linked axes, which force a one-speed-fits-all approach.

Ultra-Precision Meets Automotive OEM Standards: The ±0.02mm repeat positioning accuracy (verified via Zeiss CMM) ensures parts meet tight tolerances for automotive assembly—e.g., 20KG aluminum suspension brackets with 0.03mm hole alignment for bolt fitting. A German auto OEM supplier used 5 of these robots to produce parts for BMW, achieving 99.8% pass rate in quality audits (vs. 92% with manual handling). The robot’s gripper (customizable for part shape) uses pressure sensors to apply 50-200N force—enough to hold parts securely without crushing (critical for thin-walled aluminum components like electronics housings).

24/7 Operation Slashes Labor Costs by 60%: The robot works continuously with no breaks, holidays, or fatigue—replacing 2 full-time workers per machine. A Mexican die casting factory with 4 robots cut monthly labor costs from \(18,000 to \)7,200. The integrated auto-lubrication system (fills servo motor bearings every 8 hours) eliminates 2 hours of weekly manual lubrication, freeing maintenance teams for other tasks. For night shifts, the robot’s remote monitoring (via mobile app) lets managers track production without on-site presence— a U.S. factory reduced night shift supervision by 100%, saving $4,500/month.

Seamless Integration with Die Casting Lines: Supports Modbus-TCP and Ethernet/IP protocols, enabling synchronization with die casting machines, conveyors, and MES systems. It automatically adjusts to machine cycle times (e.g., waits for mold opening before loading) and sends production data (parts made, error logs) to MES for traceability. A Korean electronics factory integrated 3 robots with their SAP MES, achieving real-time inventory tracking and cutting order fulfillment time by 20%. The robot also has a “quick-change” gripper system—swap grippers for different parts in 3 minutes (vs. 15 minutes for traditional robots), ideal for factories with mixed-order production.

Durable Design for Harsh Die Casting Environments: The arm is made of 6061-T6 aluminum alloy (tensile strength 310MPa) that resists bending under 20KG loads—no deformation after 1 million cycles. Electrical components have an IP54 rating (dust-tight, water-resistant), protecting against aluminum dust and coolant splashes. Our tests show the robot operates reliably in 0-60℃ temperatures (common in die casting workshops) with no performance loss. A Thai zinc die casting factory used 2 robots for 3 years with zero major component replacements, vs. 1 replacement/year for cheaper robots with plastic arms.

| Parameter Name | Specification |

| Product Type | Fully Independent Industrial Servo Die Casting Robot |

| Payload Capacity | 20KG (Maximum; Customizable 15-25KG) |

| Axis Configuration | 6-Axis (Base Rotation, Shoulder, Elbow, Wrist 1/2/3) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Reach | 1,600mm (Horizontal); 1,000mm (Vertical) |

| Cycle Time | 35-50 Seconds (Standard Loading/Unloading) |

| Maximum Speed | 0.8m/s (Linear); 150°/s (Rotational) |

| Servo Motor | 6×1.5kW Panasonic/Fanuc Servo Motors (Fully Independent) |

| Control System | Siemens S7-1500 PLC + 10-Inch HMI Touchscreen (Multi-Language) |

| Programming Method | Teach Pendant (Lead-Through), Recipe Storage (100+ Groups) |

| Communication Protocols | Modbus-TCP, Ethernet/IP, OPC UA (Optional) |

| Compatible Die Casting Machines | 200T-800T Cold-Chamber (LH, Yizumi, Haitian, Fanuc, Toshiba) |

| Safety Features | Light Curtains, Emergency Stops (3 Points), Overload Protection (25KG Max), Collision Detection |

| Operating Temperature Range | 0℃-60℃ |

| Protection Rating | IP54 (Arm & Electrical Components) |

| Power Supply | 380V/50Hz (3-Phase), 7.5kW |

| Dimensions (L×W×H) | Arm: 1,700×200×180mm; Controller: 650×450×850mm |

| Net Weight | Arm: 280kg; Controller: 150kg |

| Certifications | ISO 9001, CE (EN ISO 12100), ISO 13849-1 (Category 3), RoHS |

| Gripper Compatibility | Customizable Pneumatic/Mechanical Grippers (for Aluminum/Zinc Parts) |

| Warranty | 2 Years (Arm/Servo Motors); 1 Year (Controller/Grippers) |

Automotive Parts (20KG Aluminum Brackets, Suspension Components): Ideal for 200T-500T die casting machines producing heavy aluminum auto parts. The 20KG payload handles brackets and suspension components, while ±0.02mm accuracy meets OEM standards (e.g., Ford’s 0.03mm hole tolerance). A Chinese auto parts supplier increased daily output from 800 to 1,200 parts (50% boost) by using 4 robots for 24/7 operation, meeting a $5M annual order from GM.

Industrial Machinery Parts (Pump Housings, Gear Cases): Perfect for 500T-800T machines casting 15-20KG industrial parts. The robot’s collision detection prevents damage to expensive molds (costing \(20,000+), and its fully independent servo control reaches into deep mold cavities (300mm depth) to extract parts. A German industrial machinery factory reduced mold repair costs by \)12,000/year and cut trimming time by 75% (from 2 minutes to 30 seconds per part).

Electronics Components (Large Aluminum Heat Sinks): Suitable for 200T-300T machines producing 5-15KG precision heat sinks (for data centers). The robot’s gentle gripper force (50-100N) avoids scratching heat sink fins, and its precision ensures parts align with CNC machining centers—reducing setup time by 30%. A Singapore electronics factory increased heat sink pass rate from 90% to 99%, saving $6,000/month in rework.

Multi-Machine Transfer (Inter-Line Part Movement): The robot’s 1,600mm reach connects 2-3 die casting machines to a single trimming station, eliminating manual cart transport. A Brazilian factory used 2 robots to transfer parts between 3 machines, reducing transfer time by 40% (from 5 minutes to 3 minutes per batch) and avoiding 2 hours of daily downtime from cart bottlenecks.

Payload Adjustment: Modify the robot for 15KG (lightweight parts like electronics) or 25KG (heavy industrial components) payloads—lead time 12 days. A U.S. heavy machinery factory ordered 25KG models to handle 22KG gear cases, avoiding $40,000 in extra equipment costs.

Gripper Customization: Design specialized grippers for part shapes: 1) Vacuum grippers (for flat heat sinks); 2) 2-jaw mechanical grippers (for curved brackets); 3) 4-jaw grippers (for irregular pump housings). A Korean auto parts factory needed a custom gripper for 20KG curved suspension brackets—we delivered it in 7 days, reducing part damage from 5% to 0.5%.

Control System Localization: Customize HMI language (18 options: Spanish, Japanese, German, etc.) and add region-specific safety features (e.g., OSHA-compliant emergency stops for U.S., CE-compliant light curtains for EU). We also integrate your existing MES system (SAP, Siemens Opcenter) for seamless data flow—no extra software costs.

Reach Extension: Extend the robot’s horizontal reach to 1,800mm (from 1,600mm) for large workshop layouts—ideal for factories with spaced-out machines. A Chinese die casting complex with 10 machines used extended-reach robots to avoid rearranging their production line, saving $50,000 in facility modifications.

Energy-Saving Add-Ons: Integrate a regenerative braking system (captures energy from arm lowering) to reduce power consumption by 15%. A Canadian factory added this to 5 robots, saving $3,600/year in electricity bills.

Pre-Operation Checks (5 Minutes/Day):

Servo Motor Inspection: Check for abnormal noise (grinding = bearing wear) and overheating (touch motor housing—should be ≤45℃). Use the HMI to verify servo current (should be ≤80% of rated 10A).

Gripper Test: Run a dry cycle—gripper should close firmly (hold a 20KG weight without slipping) and open smoothly. Clean gripper pads with a dry cloth (remove aluminum dust) to maintain friction.

Safety System Validation: Activate light curtains (wave a hand through—robot stops instantly) and press all 3 emergency stops (controller displays “E-Stop Active”).

Recipe Selection: Load the correct recipe (e.g., “20KG Bracket”) and run 1 test cycle without a part—ensure arm movement aligns with mold opening/closing.

Weekly Maintenance (1.5 Hours):

Lubricate Servo Joints: Apply high-temperature grease (provided) to 6 axis joints—use the grease gun included with the robot (10g per joint). Wipe excess grease to avoid dust buildup.

Clean Electrical Cabinet: Use compressed air (0.3MPa pressure) to blow dust from PLC and servo drives—dust causes overheating and component failure.

Calibrate Positioning: Use the HMI’s “Calibrate” function (takes 10 minutes) to verify ±0.02mm accuracy—place a test part in the gripper and check alignment with a digital caliper.

Monthly Maintenance (3 Hours):

Inspect Gripper Wear: Measure gripper pad thickness (replace if <5mm—original 10mm). For pneumatic grippers, check air pressure (set to 0.6MPa) and replace O-rings if leaking.

Test Collision Detection: Gently push the arm during a dry cycle—robot should reverse 10mm instantly. Adjust sensitivity via HMI if response is slow.

Update Software: Download the latest HMI firmware from our portal (free) to add new features (e.g., energy monitoring) and fix bugs. Our technical team provides remote guidance for installation.

Warranty Coverage: 2-year warranty for the robot arm and servo motors (covers manufacturing defects); 1-year warranty for the controller and grippers. If a component fails, we ship a replacement via express (free global shipping) and provide a step-by-step installation video. For servo motors, we offer a “swap service”—send a faulty motor, and we ship a replacement first (no waiting for repairs).

24/7 Technical Support: Our team of 6 die casting automation engineers (10+ years experience) offers round-the-clock help via phone, WhatsApp, and video call. For urgent issues (e.g., robot down during a rush order), we respond within 20 minutes—85% of problems resolved remotely in 1 hour. A Mexican factory fixed a servo motor error in 30 minutes, avoiding 3 hours of downtime.

Spare Parts Supply: Stock core spare parts (servo motors, gripper pads, control boards) in 4 regional warehouses (China, Germany, U.S., Brazil). For urgent needs, we offer 24-hour delivery to major industrial hubs— a U.S. factory received a replacement gripper in 14 hours, minimizing downtime to 1 hour.

On-Site Training: Free 3-day on-site training for your operators and maintenance team—covers programming, troubleshooting, and advanced features (e.g., recipe optimization). A Thai factory’s team reduced error-related downtime by 70% after training, mastering skills like “adjusting servo speed for fragile parts.”

Productivity Audit: 6 months after purchase, our engineers visit your site to analyze production data—suggesting efficiency gains (e.g., optimizing cycle time, adding gripper quick-change). A Chinese auto parts factory increased output by 15% (from 1,200 to 1,380 parts/day) after implementing our recommendations.

Specialization in Die-Casting Robots: We don’t make generic industrial robots—we focus exclusively on die casting automation. Our R&D team works with 30+ die casting factories yearly, testing robots in real conditions (aluminum dust, high temperatures, 24/7 operation) to solve actual pain points (part damage, labor costs, downtime).

Proven B2B Track Record: Over 400 die casting manufacturers in 42 countries use our robots, including suppliers to Toyota, BMW, and Siemens. A Chinese auto parts cooperative with 10 robots reduced annual labor costs by $120,000 and increased revenue by 35%—they renewed their annual maintenance contract for the 4th time.

Transparent ROI for B2B Operations: We provide a customized ROI calculator (based on your labor costs, part damage rates, and production volume). Most clients recoup investment in 10-14 months—for a factory with 3 robots, this means $180,000 in 5-year savings (labor + scrap + downtime).

Technical Expertise in Servo Automation: We hold 3 patents for fully independent servo control (e.g., axis synchronization algorithm) and partner with Panasonic/Fanuc for high-quality servo components. Our engineers can answer die-casting-specific questions (e.g., “How to handle thin-walled 20KG parts?”) — no generic automation advice.

Flexible Lead Times for Urgent Orders: Standard 20KG robots are in stock (delivery 5-7 days). Customized models take 12-18 days—50% faster than competitors (25+ days). A Brazilian factory received 3 custom 25KG robots in 15 days, meeting a $2M rush order for industrial gear cases.

Q1: Is this robot compatible with our existing 500T Yizumi die casting machine (model DM500) and our SAP MES system?

Q2: How difficult is it to program the robot for a new 18KG aluminum pump housing (our current part is a 20KG bracket)?

Q3: Can the robot handle our thin-walled 15KG aluminum heat sinks (wall thickness 2mm) without causing deformation?

Q4: What is the robot’s power consumption, and can it operate on our factory’s 380V 3-phase power supply?