EMAIL:

sales@longhuamachine.com

TELL/whatsapp:

+86-18905522221  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

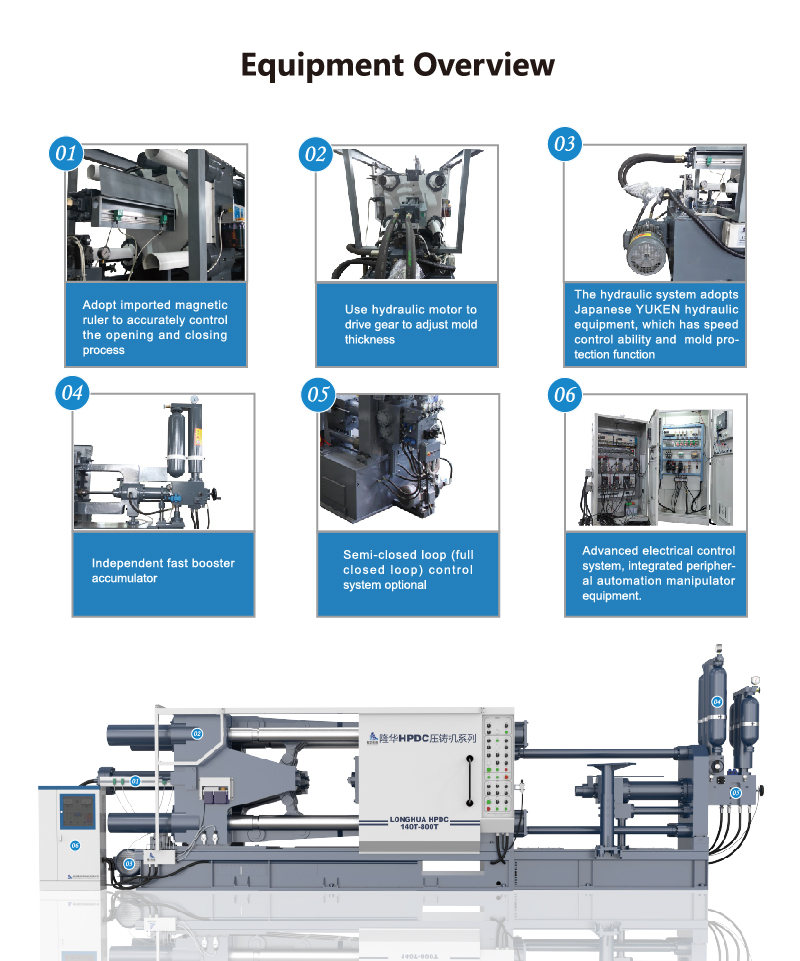

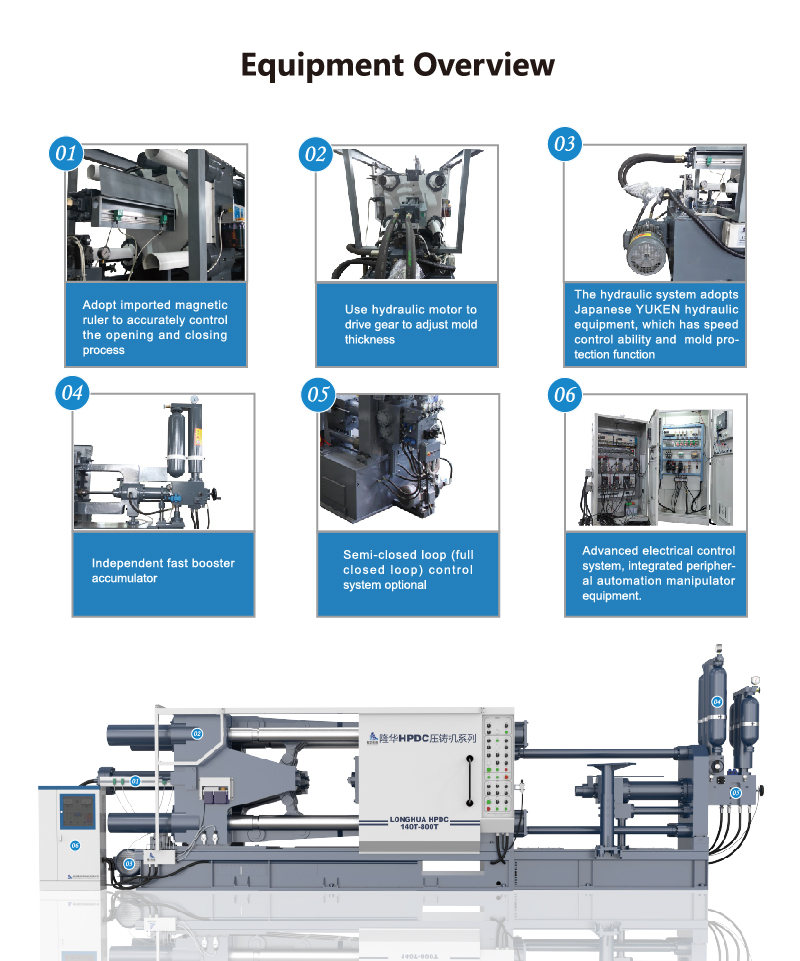

The LH-900T die casting machine is a highly efficient cold chamber die casting machine. It is designed for automotive and motorcycle parts manufacturing.

The machine offers a powerful PLC control system for precise operation. It provides high productivity with minimal downtime.

| Parameter | Value |

| Machine Type | Cold Chamber Die Casting Machine |

| Weight | 6700 kg |

| Warranty | 1 year |

| Video Factory Inspection | Provided |

| Machine Test Report | Provided |

| Core Component | PLC |

| Max Mold Block Thickness | 550 mm |

| Min Mold Block Thickness | 200 mm |

| Ejection Force | 110 kN |

| Ejection Stroke | 80 mm |

| Dimensions (LxWxH) | 5.22 x 1.5 x 2.35 meters |

| Key Selling Point | High production efficiency |

High Production Efficiency

Advanced die casting technology enables continuous casting. This increases production speed and reduces labor costs.

Precision Casting

Ensures accuracy and consistency for applications such as motorcycle parts. Ideal for manufacturers who require high quality and tight tolerances.

Brand New Warranty

This machine is sold as brand new. Both the core components and the entire machine come with a 1-year warranty, giving manufacturers peace of mind.

Full Support

Full support from the manufacturer, including video factory inspections and machine test reports. Engineers provide ongoing after-sales support and maintenance.

Customizable and Versatile

Suitable for a variety of applications, including the foundry industry. Capable of producing parts of different sizes. With customized options such as aluminum casting, it is ideal for manufacturers with a diverse product line.

Increase Production Speed

The efficient design of this machine ensures faster cycle times, thus increasing overall production output.

Cost Savings

Reduced labor costs due to automation and faster production cycles provide a more cost-effective solution.

Stable Quality

Precise control of the casting process ensures consistent product quality that meets strict industry standards.

Rugged and Durable

Made of high-quality materials, the LH-900T machine is designed for long-term reliable operation in demanding environments.

Flexible Applications

The machine can cast a variety of materials, such as aluminum, to meet different production needs.

Minimum Downtime

The low-maintenance design and excellent after-sales support ensure minimal downtime, keeping production schedules on track.

Auto Parts

Ideal for casting automotive and motorcycle parts, especially those with complex shapes or tight tolerances.

Motorcycle Parts

Ideal for producing high-precision motorcycle parts, ensuring reliability and safety under demanding conditions.

Heavy Machinery

Can be used to cast parts for agricultural and construction machinery, supporting a variety of industrial applications.

Marine Parts

The machine is capable of casting durable parts used in the marine industry, including marine parts.

1. What is the purpose of LH-900T die casting machine?

The LH-900T die casting machine is designed for high-precision casting of automotive and motorcycle parts. It is ideal for producing durable and reliable parts that meet strict quality standards.

2. What are the main features of LH-900T die casting machine?

Main features include high production efficiency, precise casting, customizable functions and one-year warranty. The machine is equipped with advanced PLC control to improve accuracy and consistency.

3. How efficient is LH-900T die casting machine?

Due to the use of advanced die casting technology, the machine has high production efficiency. It is capable of continuous casting, speeding up production and reducing labor costs.

4. Can LH-900T die casting machine be customized?

Yes, LH-900T die casting machine is customizable. It supports a wide range of applications and can cast materials such as aluminum, suitable for a variety of industries.

The LH-900T die casting machine is a highly efficient cold chamber die casting machine. It is designed for automotive and motorcycle parts manufacturing.

The machine offers a powerful PLC control system for precise operation. It provides high productivity with minimal downtime.

| Parameter | Value |

| Machine Type | Cold Chamber Die Casting Machine |

| Weight | 6700 kg |

| Warranty | 1 year |

| Video Factory Inspection | Provided |

| Machine Test Report | Provided |

| Core Component | PLC |

| Max Mold Block Thickness | 550 mm |

| Min Mold Block Thickness | 200 mm |

| Ejection Force | 110 kN |

| Ejection Stroke | 80 mm |

| Dimensions (LxWxH) | 5.22 x 1.5 x 2.35 meters |

| Key Selling Point | High production efficiency |

High Production Efficiency

Advanced die casting technology enables continuous casting. This increases production speed and reduces labor costs.

Precision Casting

Ensures accuracy and consistency for applications such as motorcycle parts. Ideal for manufacturers who require high quality and tight tolerances.

Brand New Warranty

This machine is sold as brand new. Both the core components and the entire machine come with a 1-year warranty, giving manufacturers peace of mind.

Full Support

Full support from the manufacturer, including video factory inspections and machine test reports. Engineers provide ongoing after-sales support and maintenance.

Customizable and Versatile

Suitable for a variety of applications, including the foundry industry. Capable of producing parts of different sizes. With customized options such as aluminum casting, it is ideal for manufacturers with a diverse product line.

Increase Production Speed

The efficient design of this machine ensures faster cycle times, thus increasing overall production output.

Cost Savings

Reduced labor costs due to automation and faster production cycles provide a more cost-effective solution.

Stable Quality

Precise control of the casting process ensures consistent product quality that meets strict industry standards.

Rugged and Durable

Made of high-quality materials, the LH-900T machine is designed for long-term reliable operation in demanding environments.

Flexible Applications

The machine can cast a variety of materials, such as aluminum, to meet different production needs.

Minimum Downtime

The low-maintenance design and excellent after-sales support ensure minimal downtime, keeping production schedules on track.

Auto Parts

Ideal for casting automotive and motorcycle parts, especially those with complex shapes or tight tolerances.

Motorcycle Parts

Ideal for producing high-precision motorcycle parts, ensuring reliability and safety under demanding conditions.

Heavy Machinery

Can be used to cast parts for agricultural and construction machinery, supporting a variety of industrial applications.

Marine Parts

The machine is capable of casting durable parts used in the marine industry, including marine parts.

1. What is the purpose of LH-900T die casting machine?

The LH-900T die casting machine is designed for high-precision casting of automotive and motorcycle parts. It is ideal for producing durable and reliable parts that meet strict quality standards.

2. What are the main features of LH-900T die casting machine?

Main features include high production efficiency, precise casting, customizable functions and one-year warranty. The machine is equipped with advanced PLC control to improve accuracy and consistency.

3. How efficient is LH-900T die casting machine?

Due to the use of advanced die casting technology, the machine has high production efficiency. It is capable of continuous casting, speeding up production and reducing labor costs.

4. Can LH-900T die casting machine be customized?

Yes, LH-900T die casting machine is customizable. It supports a wide range of applications and can cast materials such as aluminum, suitable for a variety of industries.