EMAIL:

info@longhuamachine.com

TELL/whatsapp:

+8619305527239  English

English English

English| Availability: | |

|---|---|

| Quantity: | |

LH-HDC-130T

LONGHUA

It utilizes the hot chamber process, where the molten metal is fed directly into the machine's chamber, enabling rapid and consistent casting cycles. This machine is capable of handling various metals, such as zinc and aluminum alloys, and is particularly suitable for manufacturing complex and high - quality metal components in mass production settings. Its robust construction and advanced technology ensure high - efficiency production while maintaining excellent casting quality and dimensional accuracy.

High Pressure Casting

Delivers a maximum clamping force of 130 tons to ensure precise and stable mold closure during the casting process. This high - pressure capability allows for the production of dense, high - quality castings with minimal porosity.

Efficient Metal Melting

Equipped with a high - efficiency melting furnace that maintains metal in a molten state for continuous production. The furnace's advanced heating system ensures uniform temperature distribution and efficient metal melting.

Accurate Metering System

Precisely controls the amount of molten metal injected into the mold cavity, ensuring consistent product quality. The metering system can be adjusted to accommodate different casting sizes and weights.

Fast Cycling

Optimized mechanical and hydraulic systems enable quick cycling times, boosting production efficiency. The machine can operate at high speeds without compromising on casting quality.

Safety Features

Incorporates multiple safety mechanisms, including emergency stop systems, protective guards, and interlocks to protect operators and ensure safe machine operation.

User - Friendly Control Panel

Features an intuitive interface with programmable controls for easy operation and parameter adjustment. The control system allows for the storage of multiple production programs, facilitating quick changeovers between different casting jobs.

Durable Construction

Built with high - strength materials to withstand the rigorous demands of industrial production. The machine's components are precision - engineered for long - term reliability and minimal maintenance.

Custom Mold Adaptability

Can accommodate various mold designs and sizes, making it versatile for different production requirements. The mold change process is streamlined for quick and efficient setup.

Automotive Parts

Produces components such as connectors, brackets, and small - sized structural parts. Ideal for manufacturing intricate automotive components that require high precision and strength.

Electronics

Ideal for manufacturing housings, connectors, and other precision metal parts for electronic devices. The machine's accuracy ensures tight tolerances necessary for electronic components.

Home Appliances

Used to create metal components for appliances like washing machines and refrigerators. It produces durable parts that meet the functional and aesthetic requirements of household appliances.

Hardware Products

Suited for producing locks, hinges, and other metal hardware items. The machine's versatility allows for the efficient production of a wide range of hardware products.

Telecommunications

Creates metal parts for communication equipment and infrastructure. The castings produced are ideal for components that require excellent electrical conductivity and mechanical properties.

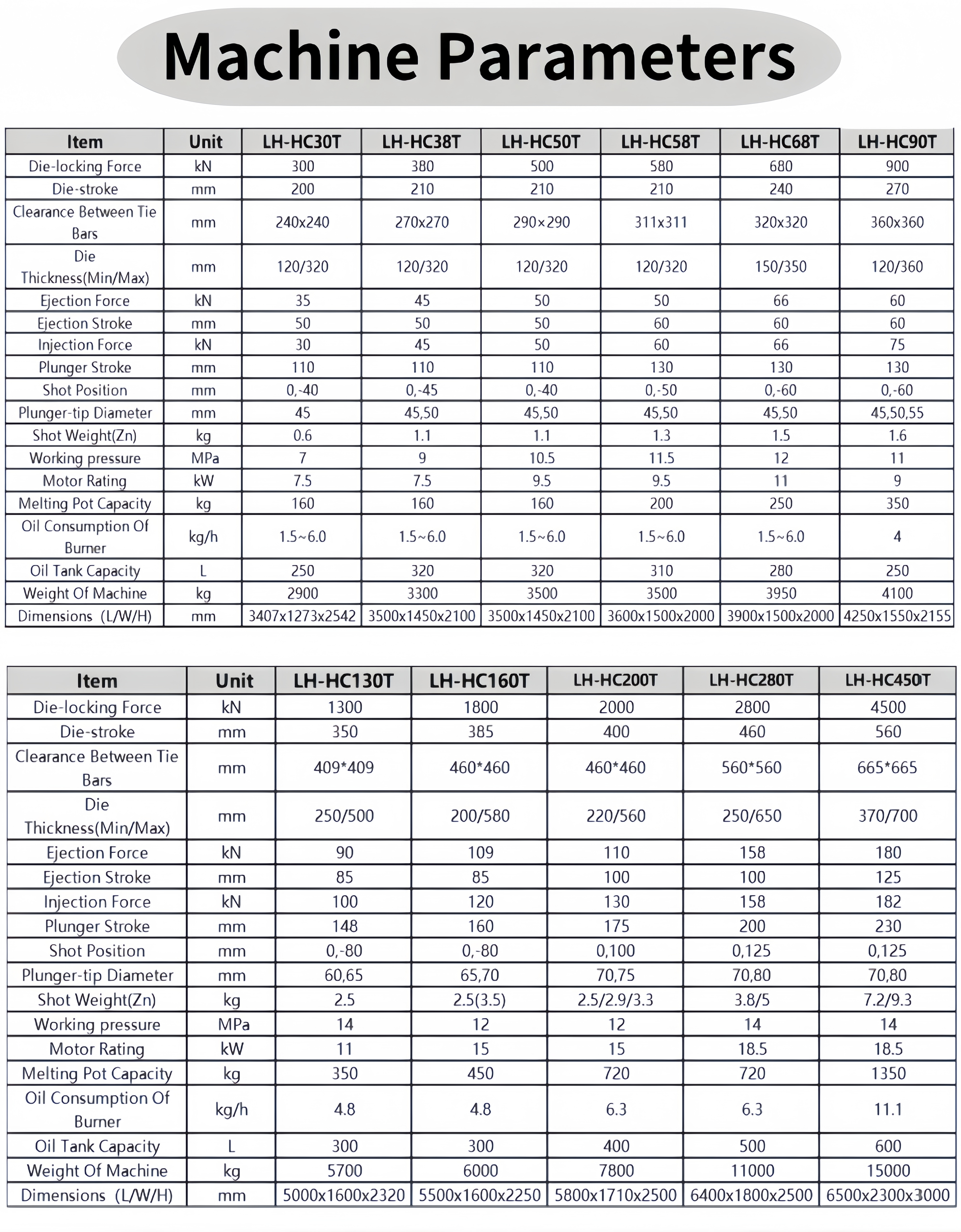

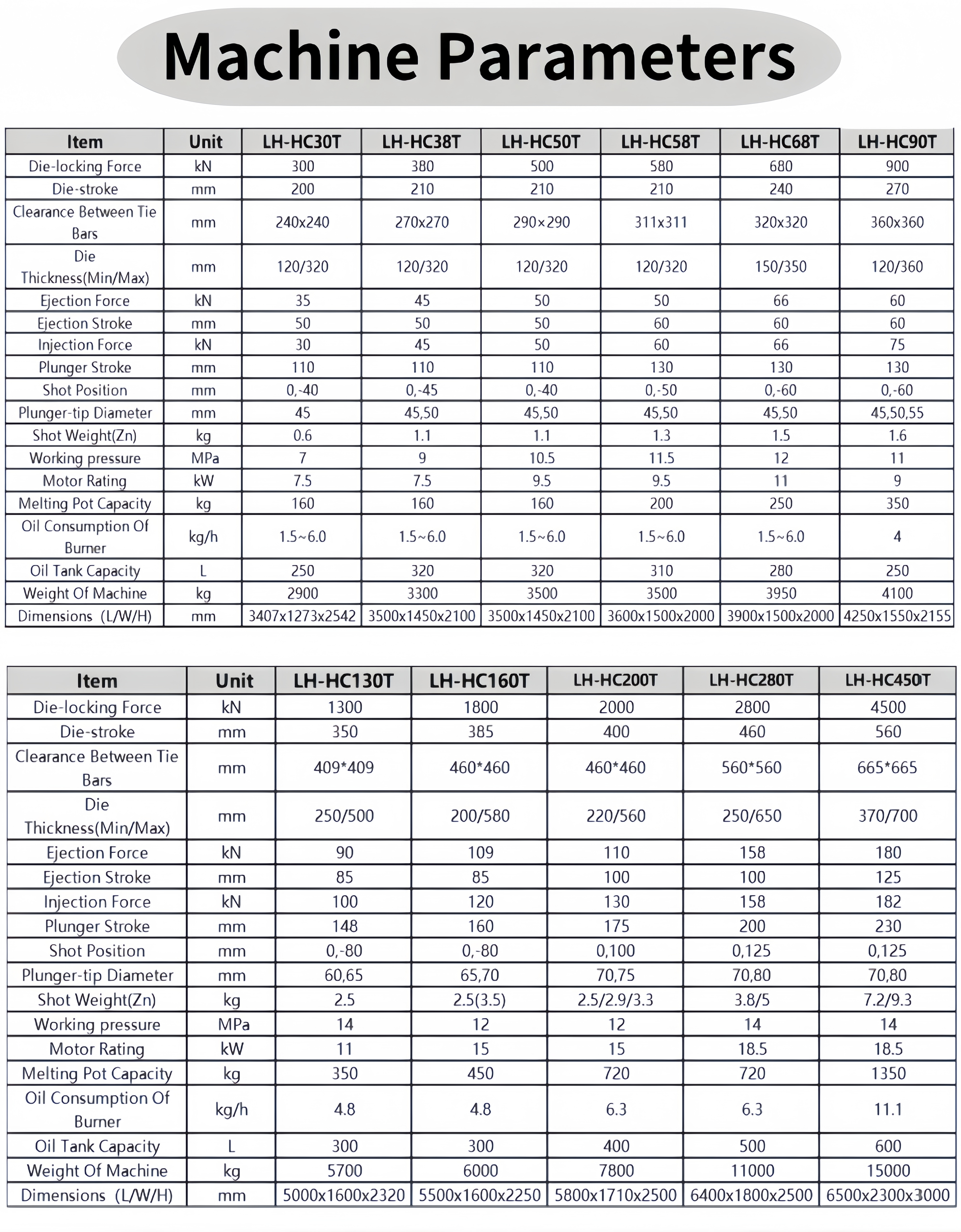

(Due to the continuous progress of science and technology, the picture,parameter configuration, etc. will not be changed without notice)

It utilizes the hot chamber process, where the molten metal is fed directly into the machine's chamber, enabling rapid and consistent casting cycles. This machine is capable of handling various metals, such as zinc and aluminum alloys, and is particularly suitable for manufacturing complex and high - quality metal components in mass production settings. Its robust construction and advanced technology ensure high - efficiency production while maintaining excellent casting quality and dimensional accuracy.

High Pressure Casting

Delivers a maximum clamping force of 130 tons to ensure precise and stable mold closure during the casting process. This high - pressure capability allows for the production of dense, high - quality castings with minimal porosity.

Efficient Metal Melting

Equipped with a high - efficiency melting furnace that maintains metal in a molten state for continuous production. The furnace's advanced heating system ensures uniform temperature distribution and efficient metal melting.

Accurate Metering System

Precisely controls the amount of molten metal injected into the mold cavity, ensuring consistent product quality. The metering system can be adjusted to accommodate different casting sizes and weights.

Fast Cycling

Optimized mechanical and hydraulic systems enable quick cycling times, boosting production efficiency. The machine can operate at high speeds without compromising on casting quality.

Safety Features

Incorporates multiple safety mechanisms, including emergency stop systems, protective guards, and interlocks to protect operators and ensure safe machine operation.

User - Friendly Control Panel

Features an intuitive interface with programmable controls for easy operation and parameter adjustment. The control system allows for the storage of multiple production programs, facilitating quick changeovers between different casting jobs.

Durable Construction

Built with high - strength materials to withstand the rigorous demands of industrial production. The machine's components are precision - engineered for long - term reliability and minimal maintenance.

Custom Mold Adaptability

Can accommodate various mold designs and sizes, making it versatile for different production requirements. The mold change process is streamlined for quick and efficient setup.

Automotive Parts

Produces components such as connectors, brackets, and small - sized structural parts. Ideal for manufacturing intricate automotive components that require high precision and strength.

Electronics

Ideal for manufacturing housings, connectors, and other precision metal parts for electronic devices. The machine's accuracy ensures tight tolerances necessary for electronic components.

Home Appliances

Used to create metal components for appliances like washing machines and refrigerators. It produces durable parts that meet the functional and aesthetic requirements of household appliances.

Hardware Products

Suited for producing locks, hinges, and other metal hardware items. The machine's versatility allows for the efficient production of a wide range of hardware products.

Telecommunications

Creates metal parts for communication equipment and infrastructure. The castings produced are ideal for components that require excellent electrical conductivity and mechanical properties.

(Due to the continuous progress of science and technology, the picture,parameter configuration, etc. will not be changed without notice)